Split-type double-balanced system small-diameter mechanical pushing device

A double-balanced, small-diameter technology, applied in the field of geological exploration, can solve the problems of difficulty in disassembly and assembly, high maintenance costs, complex overall structure of the pusher, immature and stable small-diameter pusher, etc., so as to reduce later maintenance. Cost, convenient disassembly and maintenance, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

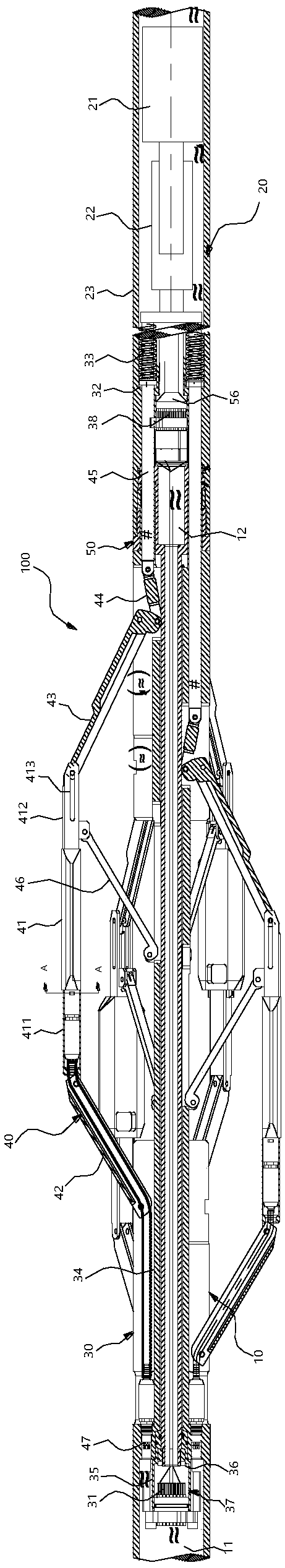

[0030] like figure 1 As shown, the split type double balance system small diameter mechanical pusher 100 according to an embodiment of the present invention generally includes a probe part 10 for contacting the well wall, and a driving part 20 for driving the probe part 10 to advance.

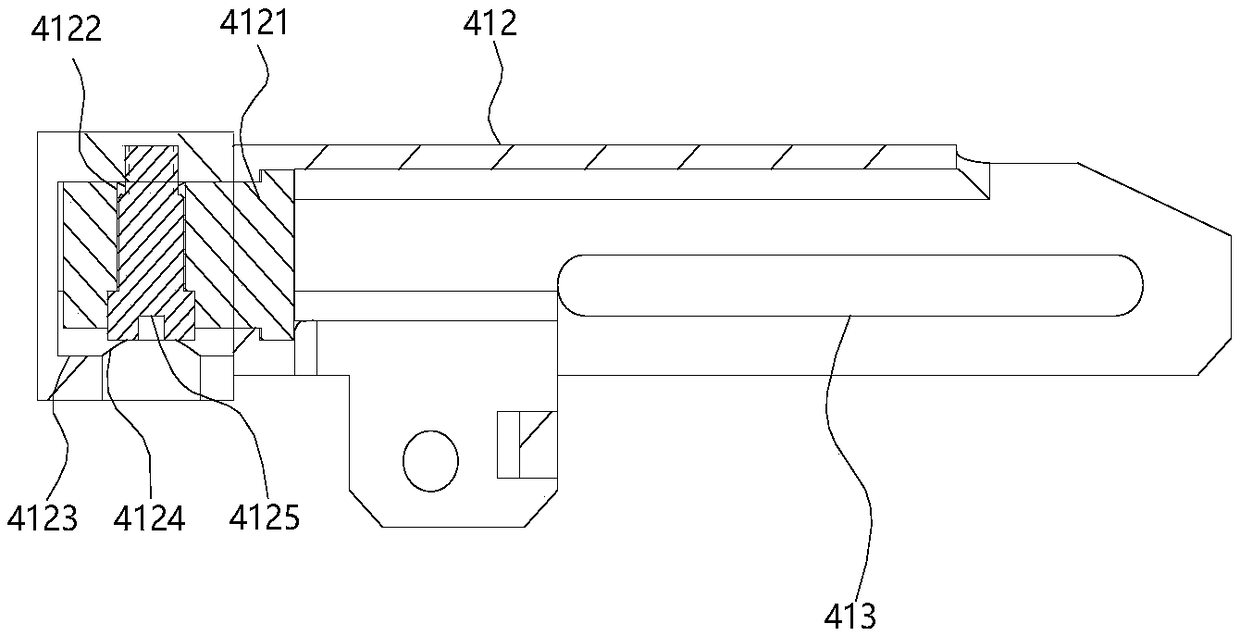

[0031] The probe part 10 includes a cylindrical main base 30, and a plurality of pushing arms 40 are evenly distributed on the outer circumference of the main base 30. Each pushing arm 40 is distributed along the axial direction and can be radially extended into a trapezoidal shape, and the trapezoid is located on the main base. The width of the bottom edge on one side of 30 is greater than the width of the top edge, forming a structure similar to an isosceles trapezoid, and the housing of the main base 30 is provided with accommodating grooves for accommodating each retracted pushing arm 40 .

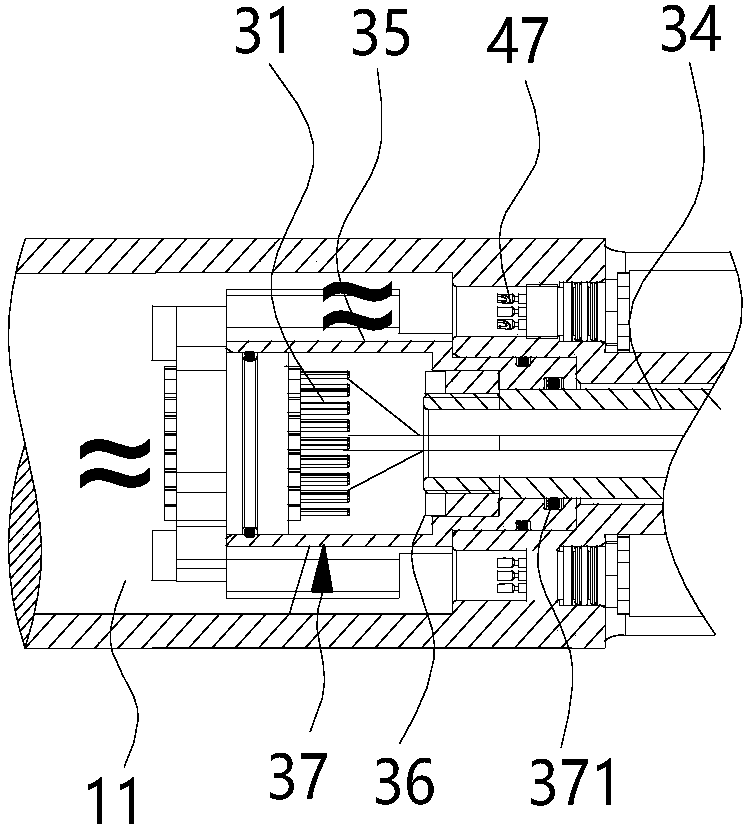

[0032] One end of the main body 30 is provided with a pressure chamber 11 for installing a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com