Pretreatment construction device for traffic road maintenance

A technology of road maintenance and construction equipment, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of affecting the use effect of the repaired road surface, reducing the service life, and easy to sag and deform, so as to reduce the construction difficulty, use for a long time, and not easily collapse. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

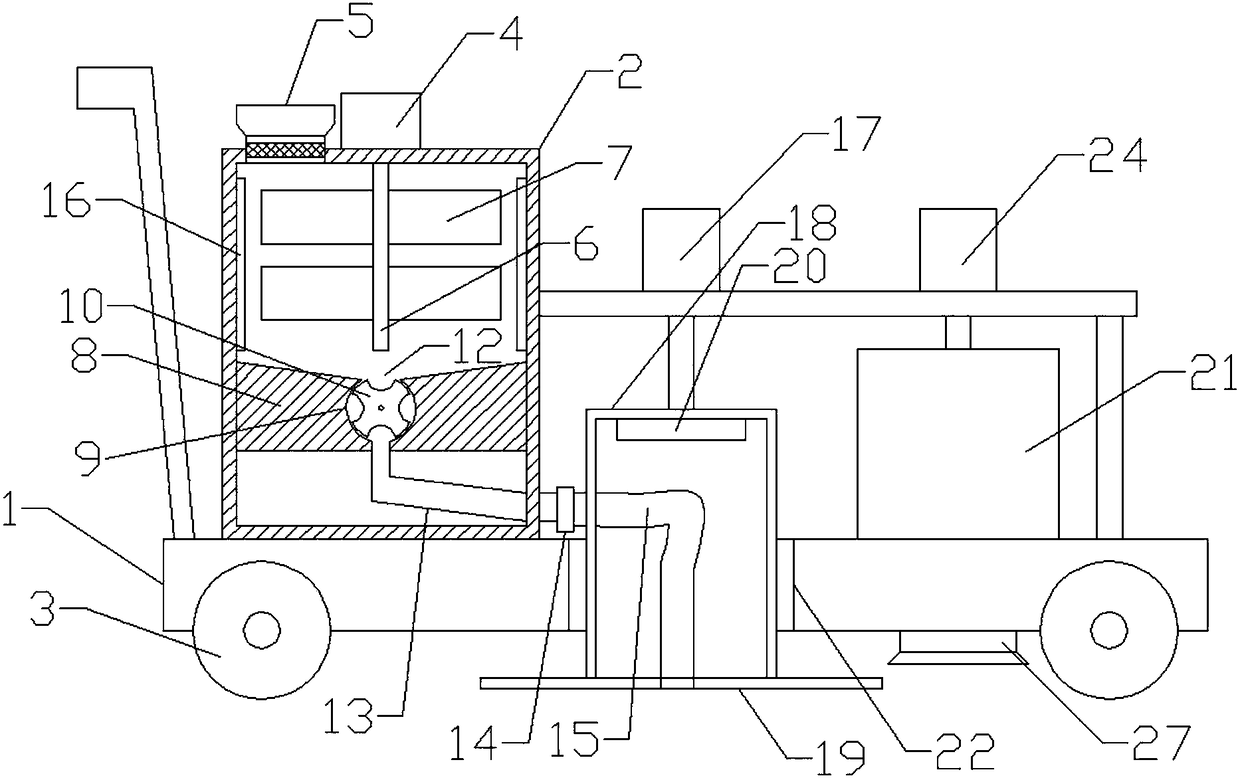

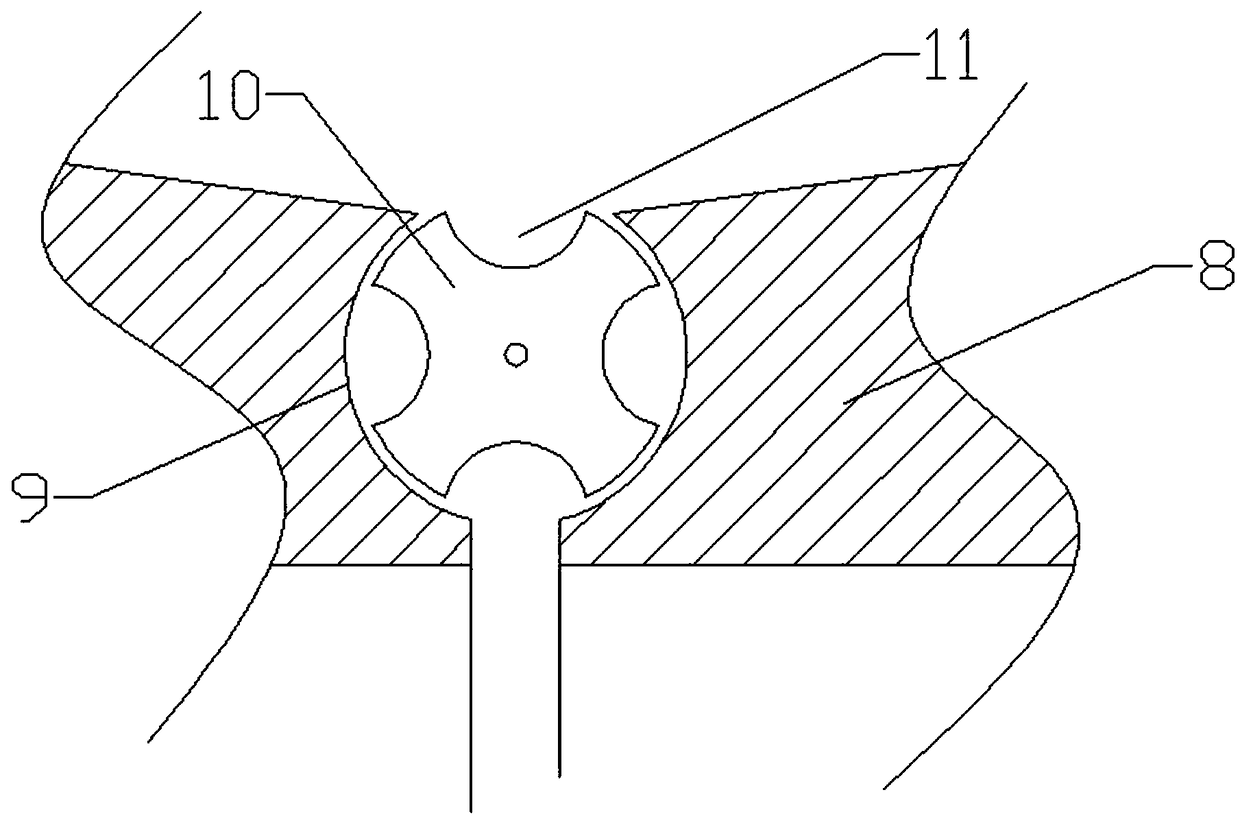

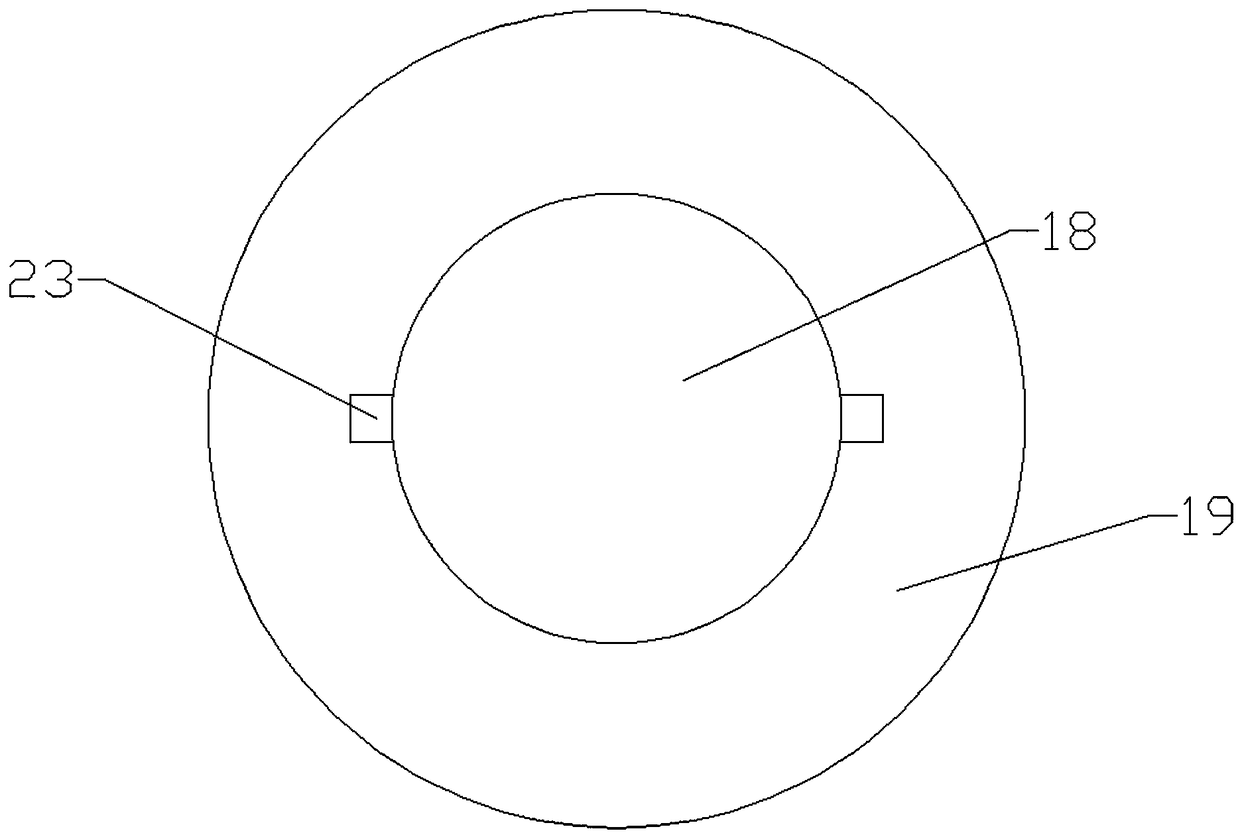

[0018] Please refer to the figure, in the embodiment of the present invention, a construction device for pretreatment of traffic road maintenance includes a base 1, a heating box 2, a roller 3, a stirring motor 4 and a feed port 5; the roller 3 is installed on the base 1 The lower side of the device makes it easy to move, the heating box 2 is fixedly installed on the base 1, the stirring motor 4 is fixed on the top of the heating box 2, and the top of the heating box 2 is also connected with a feed port 5 with a filter for The raw material is loaded into the base 1; the output shaft of the stirring motor 4 extends vertically downwards into the heating box 2, and a vertical stirring shaft 6 is fixedly connected to the lower end of the output shaft of the stirring motor 4, and the stirring shaft 6 A plurality of stirring blades 7 are fixedly installed on the side wall of the heating box 2, and the internal asphalt raw materials are stirred by the stirring blades 7, which is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com