Medium frequency induction heating coil for steel rail welding head

A technology of induction heating coils and welding heads, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of prolonged disassembly time, difficulty in disassembly of induction heating coils, large differences in shape and size, etc. Realize the effect of normalizing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

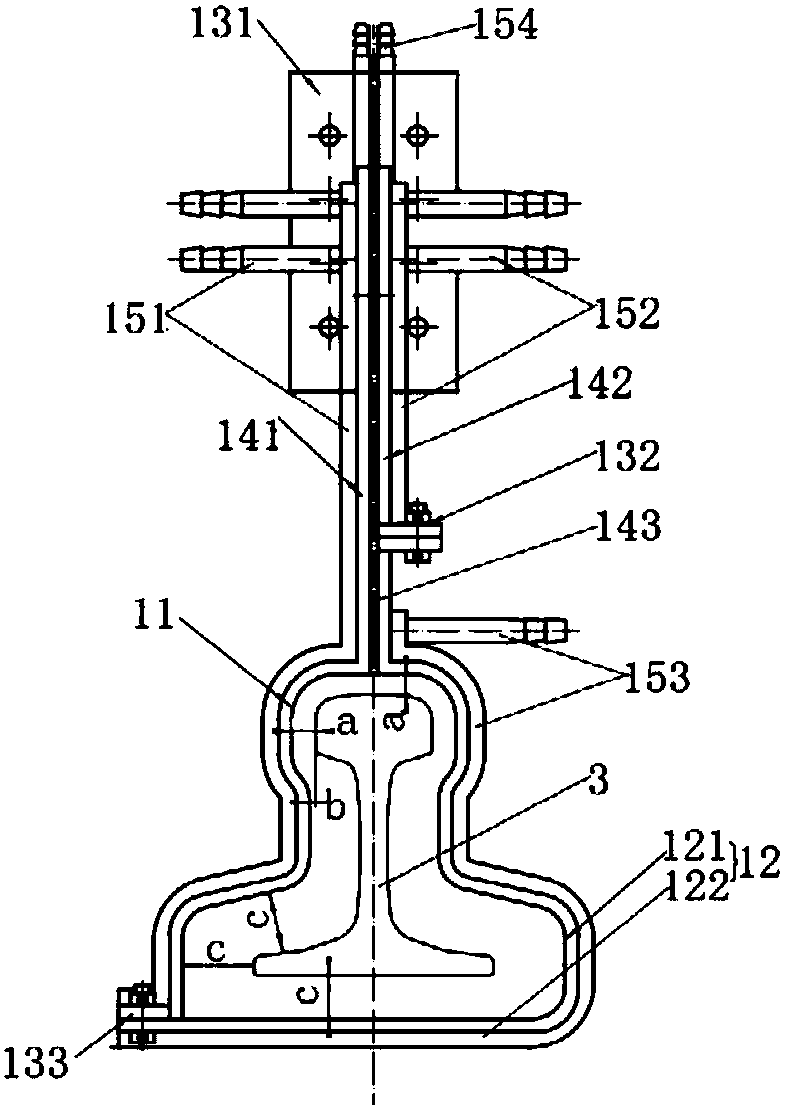

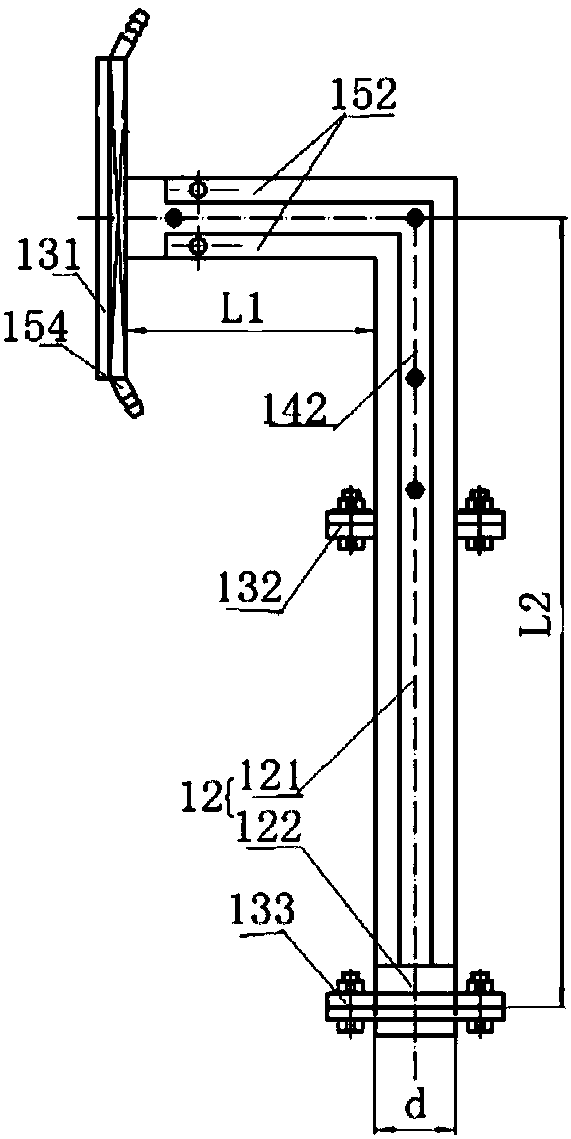

[0023] see figure 1 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

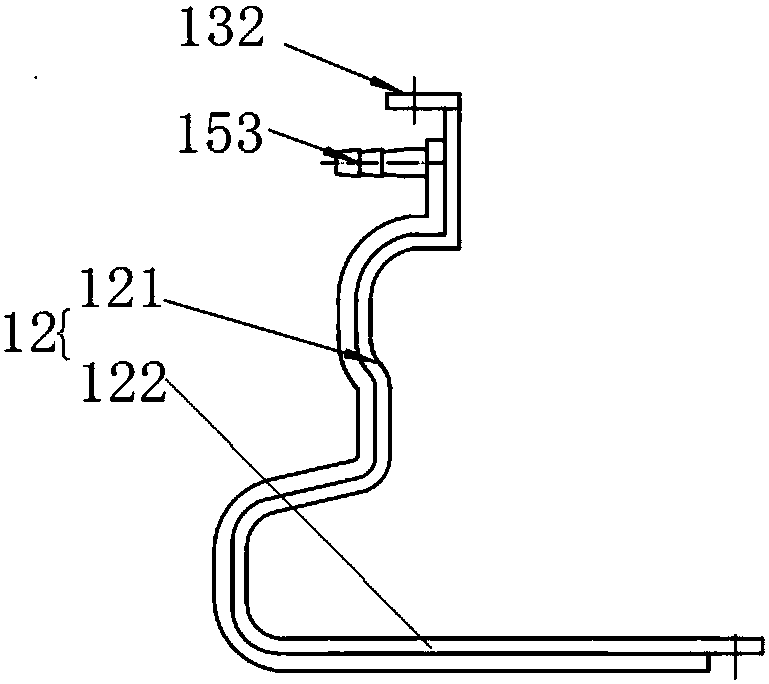

[0024] An intermediate frequency induction heating coil for a rail welding head of the present invention includes a first effective coil 11, a second effective coil 12, a top electrode plate 131, a middle electrode plate 132, a bottom electrode plate 133, a first bus bar 141, a second bus bar Rows 142 and insulating pads 143. The second effective coil 12 is divided into a longitudinal coil 121 and a horizontal coil 122 connected as one.

[0025] The first bus bar 141 is arranged perpendicular to the roadbed where the rails are located. The top of the first bus bar 141 is externally connected to a transformer through a top electrode plate 131, and the bottom of the first bus bar 141 is connected to the top of the first effective coil 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com