Multipurpose interlocking valve

A multi-purpose, interlocking technology, applied in the direction of multi-way valves, sliding valves, valve devices, etc., can solve the problems of high quality requirements for personnel and difficult processing angles, and achieve small size, overcome medium penetration and leakage, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

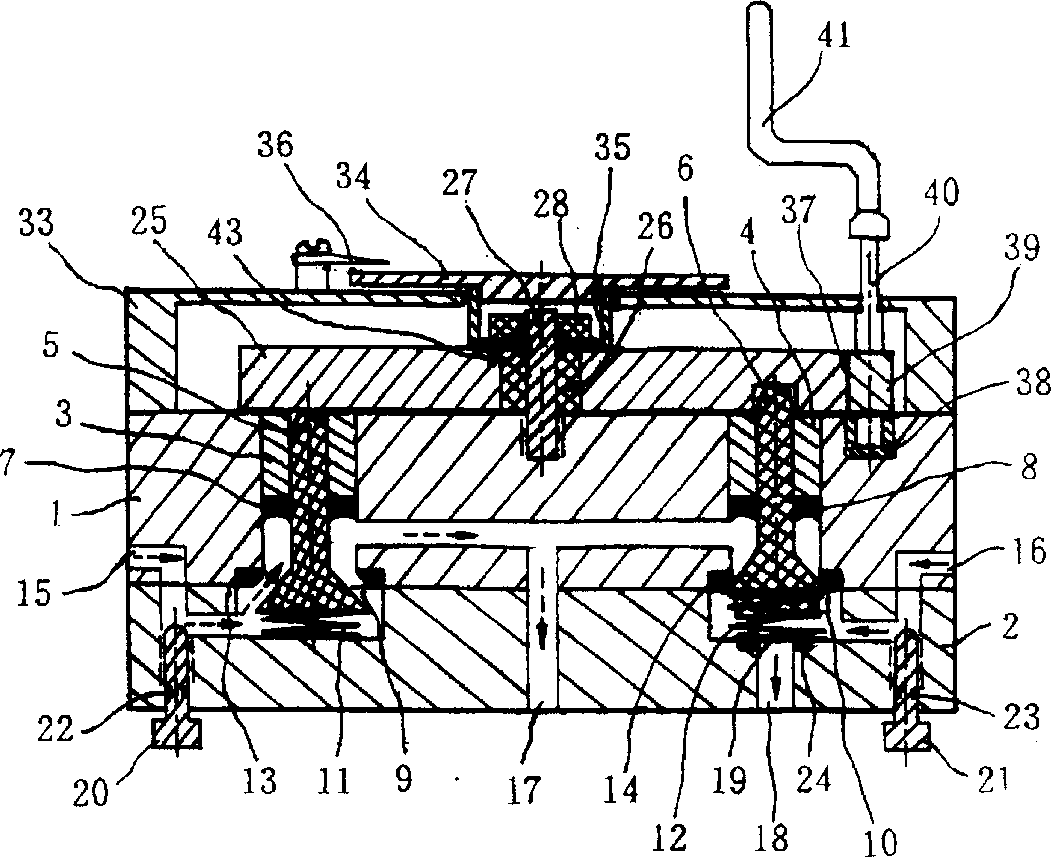

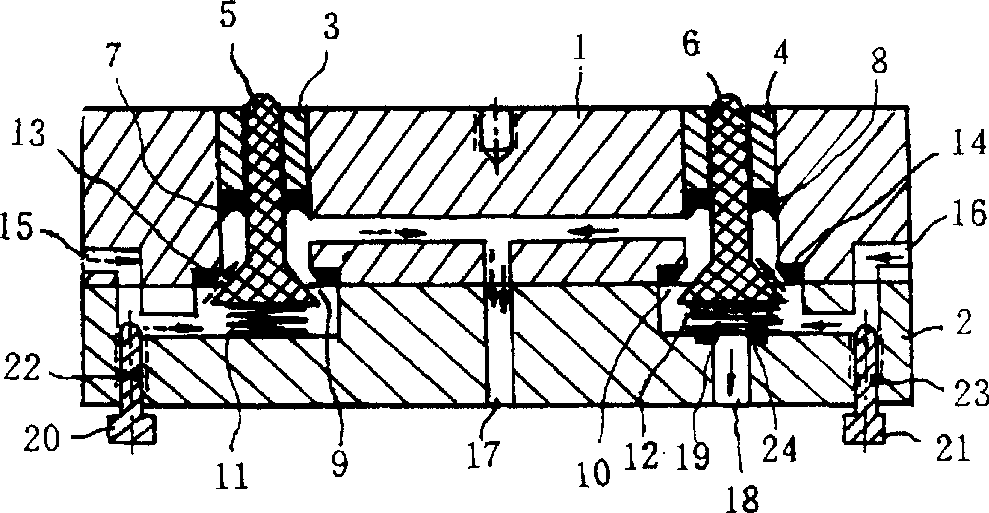

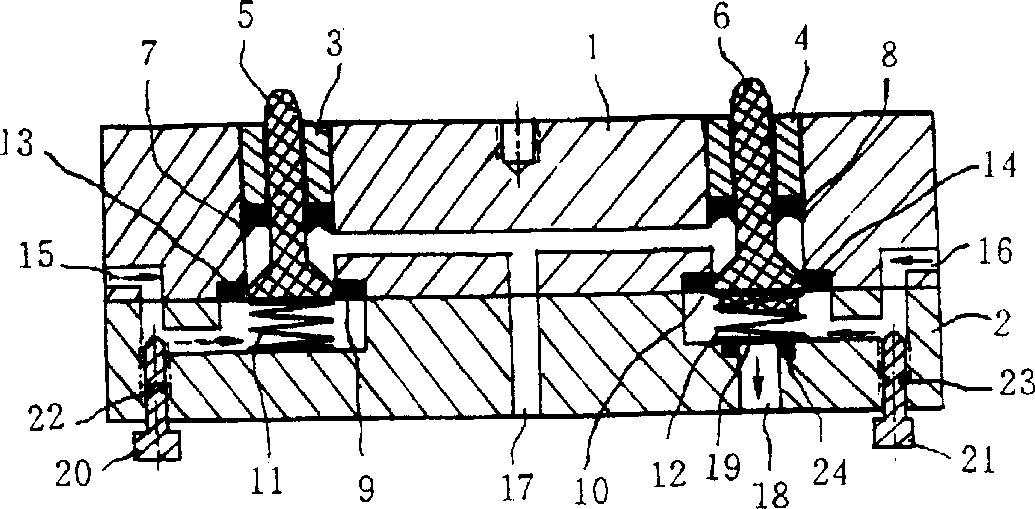

[0036] Multipurpose chain valve of the present invention is shown in accompanying drawing. There is an upper valve body 1, and the lower end of the upper valve body 1 is fixedly connected with the lower valve body 2. There are two shaft sleeves 3, 4 on the upper valve body 1, the shaft sleeves 3, 4 are equipped with up and down sliding cone valve cores 5, 6, and the lower ends of the shaft sleeves 3, 4 have herringbone sealing rings 7, 8. The lower ends of the conical spools 5,6 sliding up and down are connected with the springs 11,12 located in the valve ports 9,10. Valve ports 9 and 10 are provided with sealing seat rings 13 and 14 that are closely matched with the up and down sliding cone spools 5 and 6. Valve ports 9 and 10 have medium inlets 15 and 16 and medium outlets 17 and 18, and valve port 10 has a connected auxiliary valve port 19. Adjusting bolts 20, 21 for controlling the flow rate or pressure of various media are arranged on the channel communicating with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com