Rapid printing device for thin films

A printing device and film technology, applied in printing devices, printing, printing machines, etc., can solve the problems of low printing efficiency, cumbersome structure, and single function, and achieve the effects of improving work efficiency, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

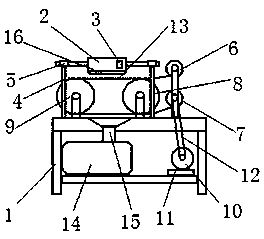

[0015] In order to make those skilled in the art better understand the technical solution of the present invention, the following in conjunction with the attached figure 1 The present invention is further analyzed.

[0016] Such as figure 1 As shown, a fast printing device for film, including: frame 1, printing machine 2, switch 3, support frame 4, height adjustment mechanism 5, feeding group 6, receiving group 7, first transmission wheel 8 , the second transmission wheel 9, motor 10, shockproof pad 11, belt 12, film 13, dryer 14, air duct 15, infrared scanning device 16; frame 1 top side is provided with support frame 4, support frame 4 It is set as a "door"-shaped structure; there are height adjustment mechanisms 5 on both sides of the top of the support frame 4, which are used to adjust the distance between the printing machine 2 and the film 13; It is an ink-type printing machine; the printing machine 2 is provided with a switch 3; the bottom of the printing machine 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com