Automobile maintenance tool and using method thereof

A vehicle maintenance and tool technology, applied in vehicle maintenance/repair, manufacturing tools, workbenches, etc., can solve the problems of inconvenient operation, manual adjustment, and inconvenient lateral displacement of the flip frame, and achieves improved efficiency, good maintenance, and good lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

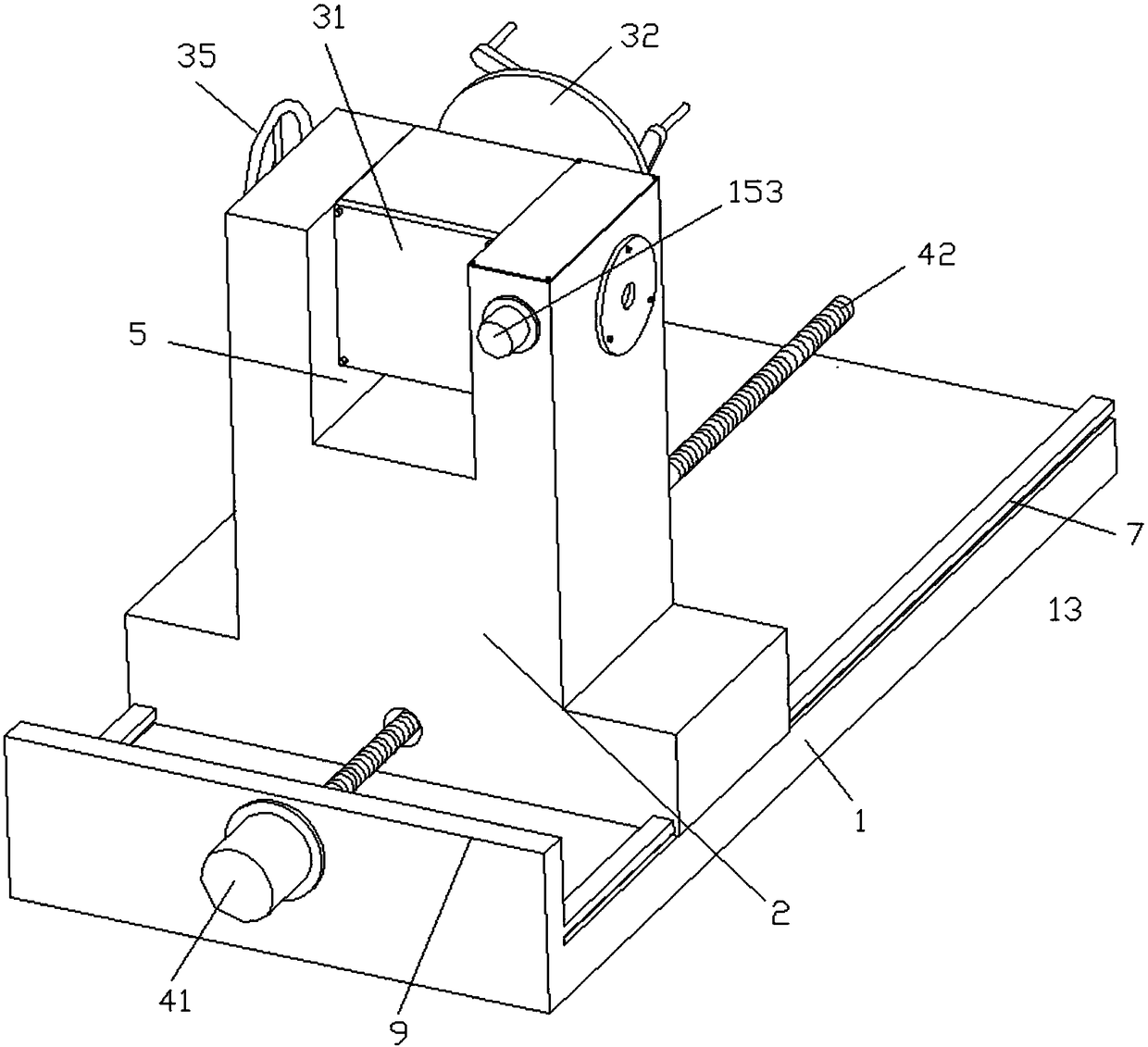

[0032] Such as Figure 1 to Figure 4 As shown, an automobile maintenance tool includes an overturning frame 3, a support 2 and a base 1. The top of the support 2 is provided with a notch 5, and two ends of the overturning frame 3 are connected with a rotating shaft 6 and rotating through the rotating shaft 6. Connected in the gap 5, the rotating shaft 6 is also connected with a rotating mechanism 15 for driving the turning frame 3 to rotate in a vertical plane, the base 1 is provided with a slide rail 7, and the cross section of the slide rail 7 is "T" The bottom of the support 2 is provided with a sliding groove 8 that is matched with the slide rail 7, a positioning plate 9 is provided at one end of the base 1, and a lateral movement mechanism 4 is installed on the positioning plate 9. The support 2 and the lateral movement The mechanism 4 is connected and can move back and forth on the slide rail 7.

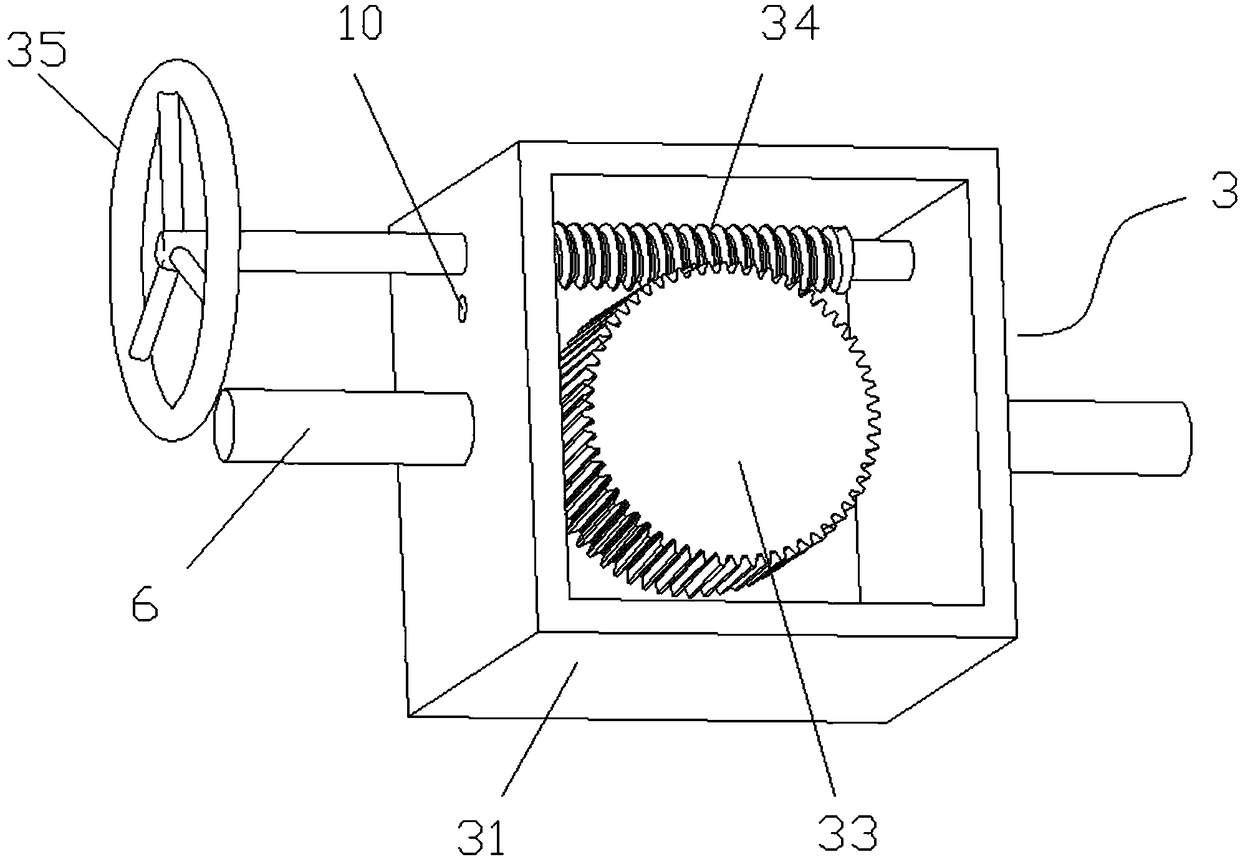

[0033] In this embodiment, the turning frame 3 includes a turning box 31, a ...

Embodiment 2

[0040] Such as Figure 5 with Image 6 As shown, an automobile maintenance tool includes an overturning frame 3, a support 2 and a base 1. The top of the support 2 is provided with a notch 5, and two ends of the overturning frame 3 are connected with a rotating shaft 6 and rotating through the rotating shaft 6. Connected in the gap 5, the rotating shaft 6 is also connected with a rotating mechanism 15 for driving the turning frame 3 to rotate in a vertical plane, the base 1 is provided with a slide rail 7, and the cross section of the slide rail 7 is "T" The bottom of the support 2 is provided with a sliding groove 8 that is matched with the slide rail 7, a positioning plate 9 is provided at one end of the base 1, and a lateral movement mechanism 4 is installed on the positioning plate 9. The support 2 and the lateral movement The mechanism 4 is connected and can move back and forth on the slide rail 7.

[0041] In this embodiment, the turning frame 3 includes a turning box 31, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com