Automatic machining device for energy-conservation and emission-reduction vehicle parts

A technology for auto parts and processing devices, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as increased product production costs, low work efficiency, and complex operation processes, and achieve high production efficiency and savings. Cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

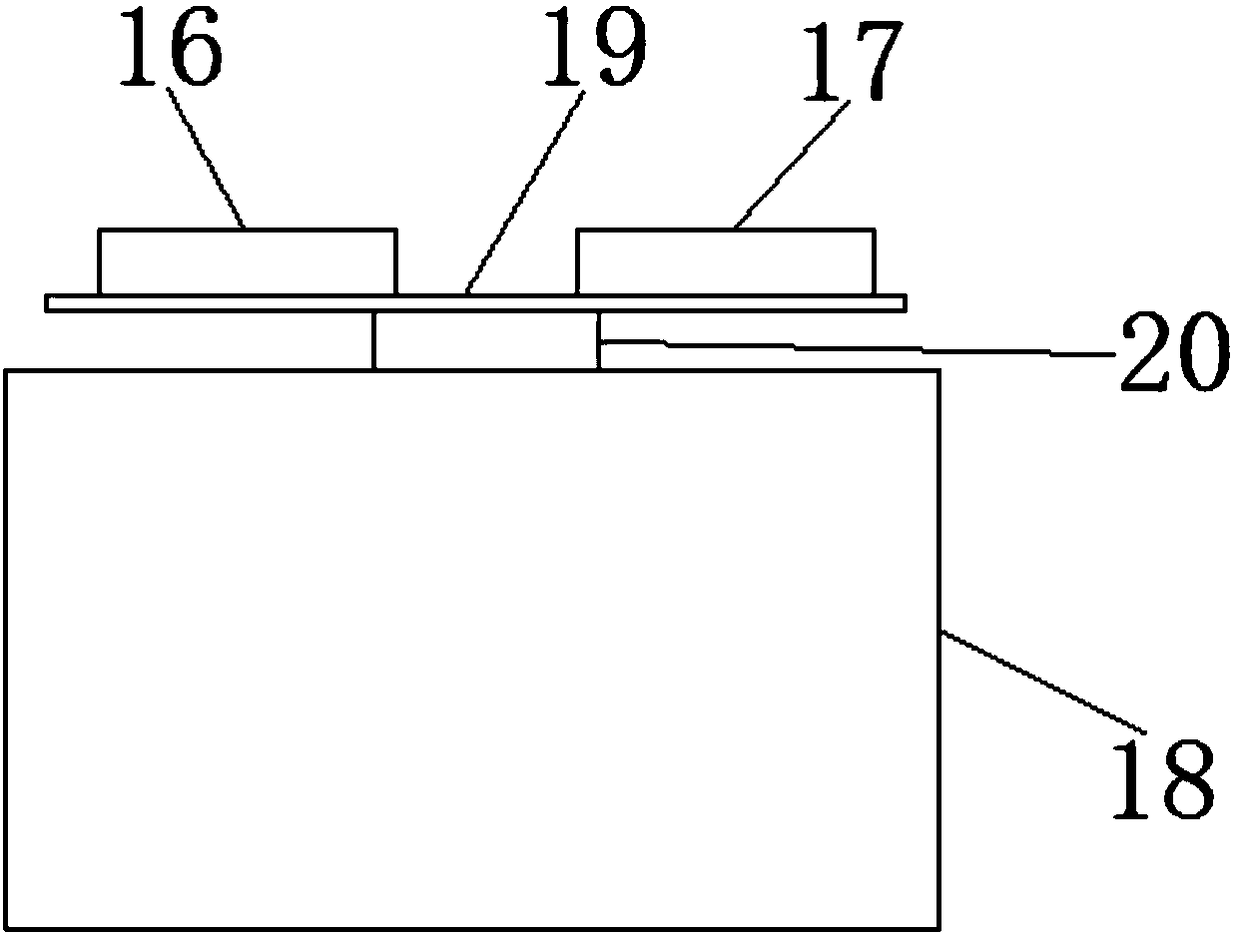

[0027] Such as figure 1 Shown is an automatic processing device for energy-saving and emission-reducing auto parts, which includes a rotating manipulator base, a manipulator 1 arranged on the rotating manipulator base, and mechanical arms 1 respectively arranged around the rotating manipulator base. The first machine tool 2, the second machine tool 3, and the product storage unit, the device also includes an electrical controller. The top of the mechanical arm 1 is provided with a rotary manipulator 4, and the rotary manipulator 4 includes a manipulator rotation mechanism arranged at the top of the robot arm 1 and a first clamping mechanism 5 and a second clamping mechanism 6 respectively arranged on the manipulator rotation mechanism. , blowing and cleaning mechanism 7, after the first clamping mechanism 5 takes off the processed finished product on the first lathe 2, the first lathe 2 is carried out blowing and cleaning by the blowing and cleaning mechanism 7, and then the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com