Small-sized part flattening device

A technology of small size and parts, which is applied in the field of small size parts flattening device, can solve the problems of large volume, high cost and inappropriate small size parts flattening of die forging equipment or devices, and achieve simple structure, low cost, The effect of facilitating multi-process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The small-sized parts flattening device of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

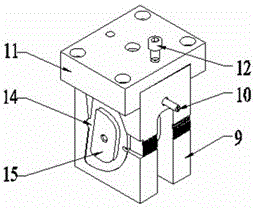

[0028] Such as Figure 1~5 As shown, a small-sized parts flattening device includes a mold 15, an adjustment mechanism, an actuator and a transmission mechanism;

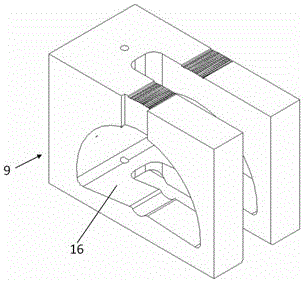

[0029] The adjustment mechanism includes an outer adjustment block 9, an inner adjustment block 14, and a top cover 11 that is arranged above the outer adjustment block 9 and is fixedly connected with the housing 13; the outer adjustment block 9 is a "ㄇ" with a rectangular side wall Type structure, the two side walls form fan-shaped grooves 16, and the lower bottom surface of the upper transverse wall forms a groove that cooperates with the upper end surface of the inner adjustment block 14;

[0030] The inner adjustment block 14 is a "ㄇ" type structure with a fan-shaped side wall, which is installed in the fan-shaped groove 16, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com