Copper tube bending and cutting machine for connecting and installing indoor and outdoor units of air conditioner

An installation and cutting machine technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inaccurate angle control, low work efficiency, high labor intensity, etc., and achieve controllable bending angle and high work efficiency. , automated and precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

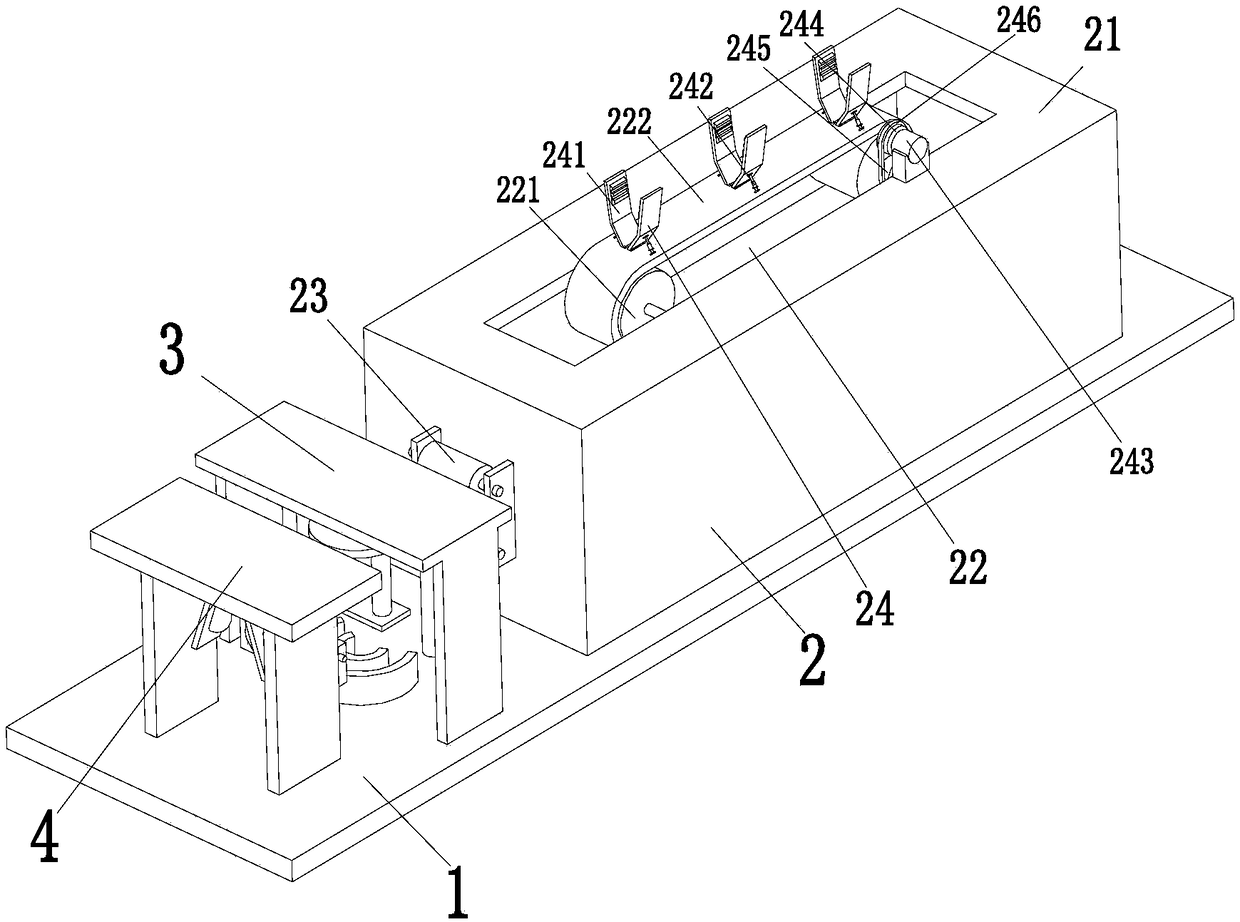

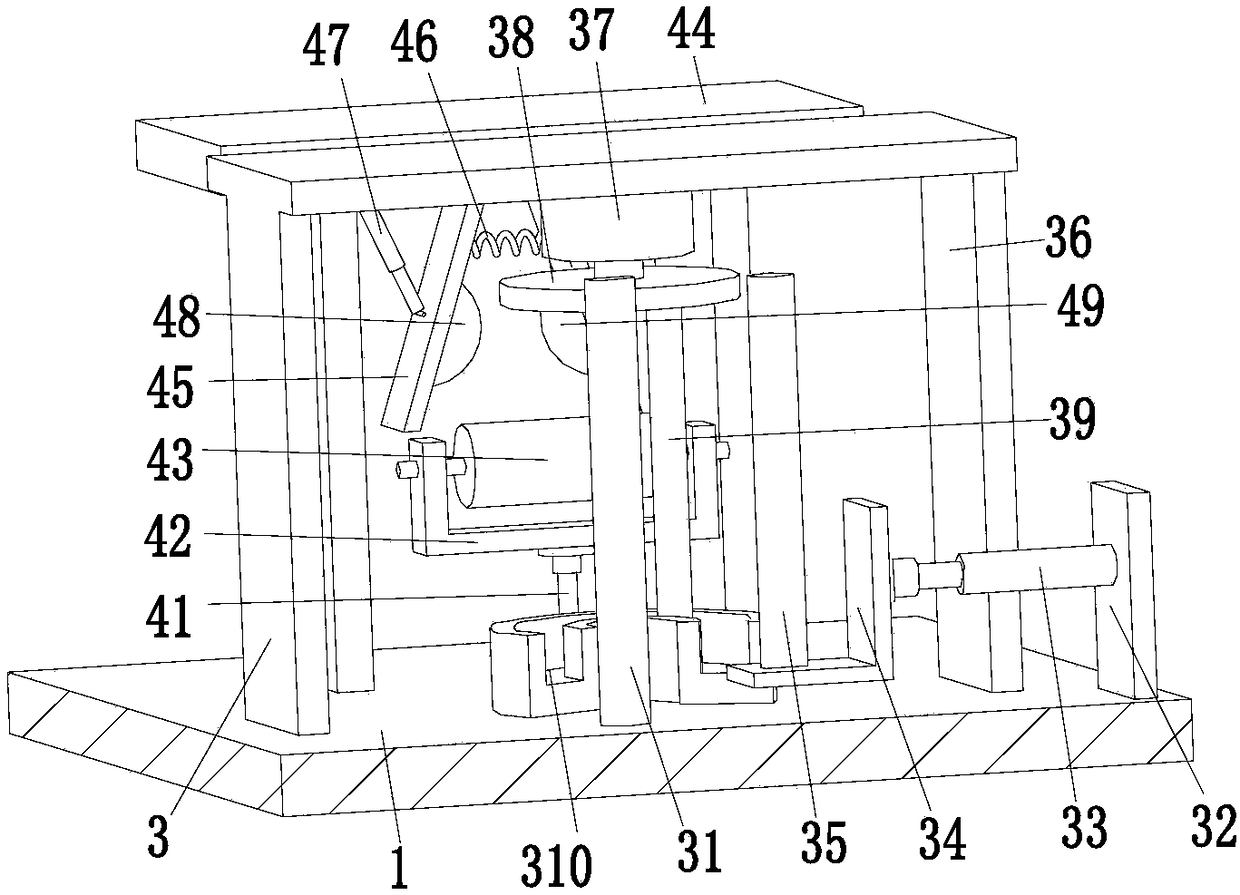

[0015] Such as Figure 1 to Figure 2 As shown, a copper pipe bending and cutting machine for connecting and installing the internal and external hosts of an air conditioner includes a base plate 1, a precise conveying device 2 is installed at the front end of the base plate 1, a controllable bending device 3 is installed in the middle of the base plate 1, and the base plate 1 The rear end is equipped with a cutting device 4, the precise conveying device 2 can transport the copper pipe according to actual needs, the controllable bending device 3 can bend the copper pipe based on the actual situation, and the cutting device 4 can automatically bend the copper pipe Cutting process, precise conveying device 2, controllable bending device 3, and cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com