Filter system with server function and working method thereof

A filtration system and filtration chamber technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve problems such as influence, time-consuming and laborious, errors, etc., to ensure effectiveness, ensure filter press quality, and save manual monitoring. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

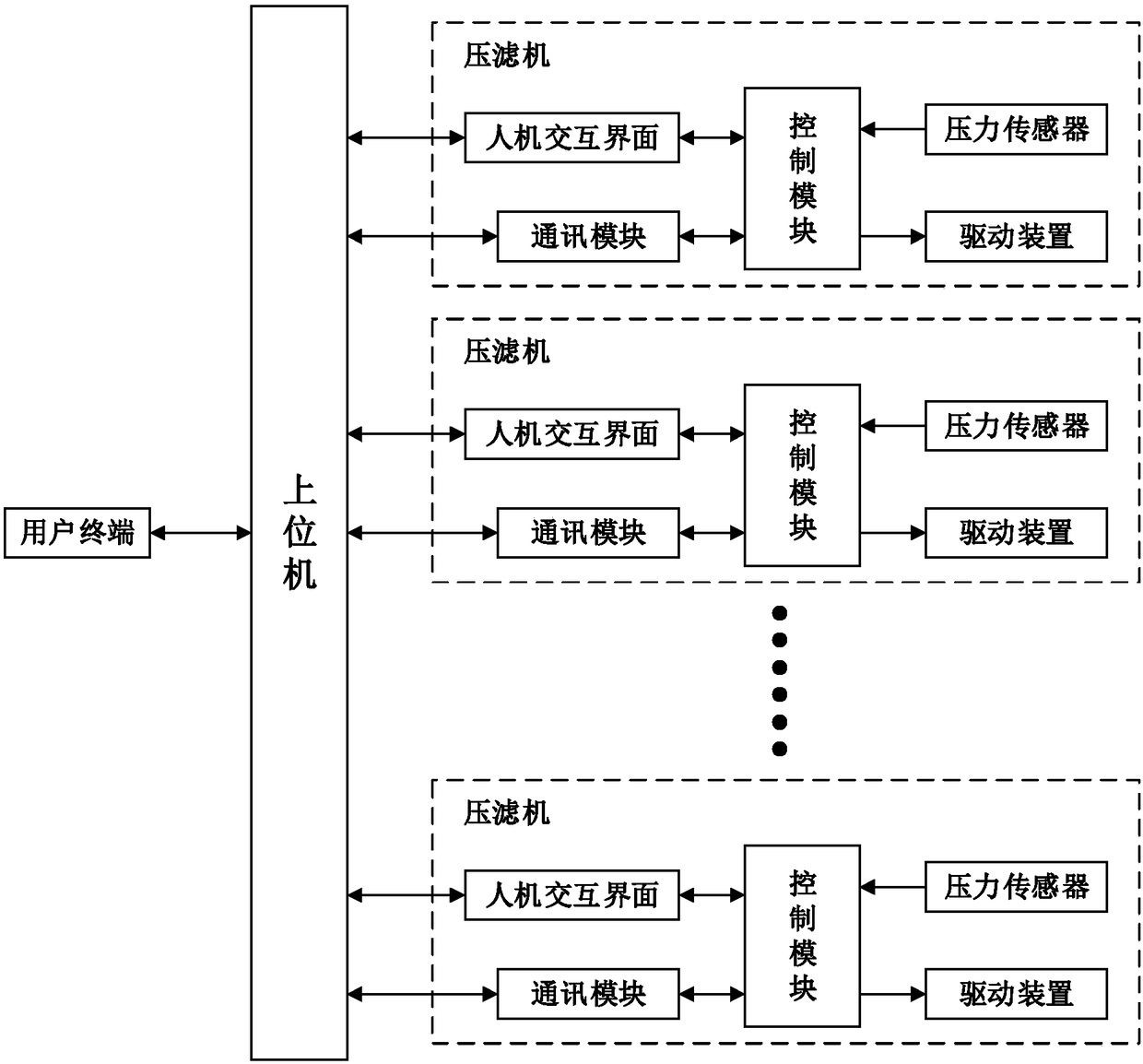

[0023] figure 1 is a functional block diagram of the filtration system of the present invention.

[0024] Such as figure 1 As shown, the present embodiment 1 provides a filtering system, including: a host computer and at least one filter press; wherein the filter press includes a control module, and the control module is suitable for collecting operating parameters of the filter press, And send the collected operating parameter data to the upper computer; the upper computer is suitable for storing the normal operating parameters of the filter press, and compares the received operating parameters according to the normal operating parameters; if the upper computer judges the received operating parameters If it is normal, save the operating parameters; if the host computer judges that the received operating parameters are abnormal, it will send the alarm information to the user terminal and / or the human-computer interaction interface connected to the control module in the corres...

Embodiment 2

[0048] On the basis of Embodiment 1, this Embodiment 2 provides a working method of a filtration system, including: a host computer and at least one filter press; wherein the filter press includes a control module, and the control module is suitable for Collecting the operating parameters of the filter press, and sending the collected operating parameter data to the host computer; the host computer is suitable for storing the normal operating parameters of the filter press, and comparing the received operating parameters according to the normal operating parameters; if If the upper computer judges that the received operating parameters are normal, it will save the operating parameters; if the upper computer judges that the received operating parameters are abnormal, it will send an alarm message to the user terminal and / or the human-machine connected to the control module in the corresponding filter press user-interface.

[0049] The filtering system in this embodiment has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com