Non-intrusive temperature monitoring sensor

A monitoring sensor, non-intrusive technology, used in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of high cost and low precision, and achieve reasonable structure, safe and reliable performance, and reduce the risk of electric shock. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

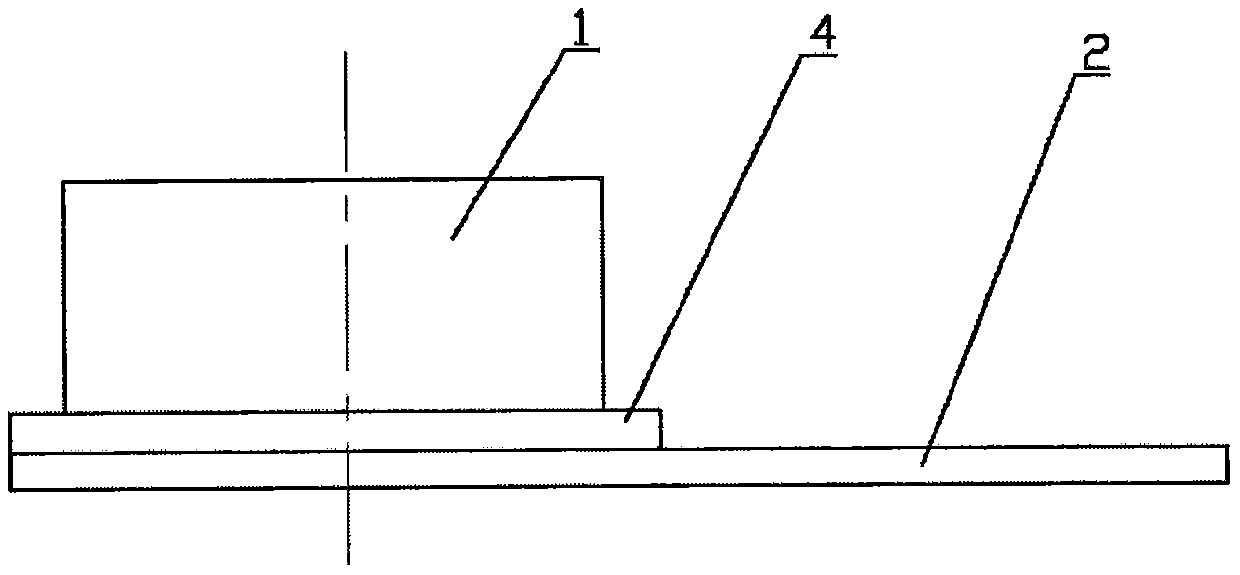

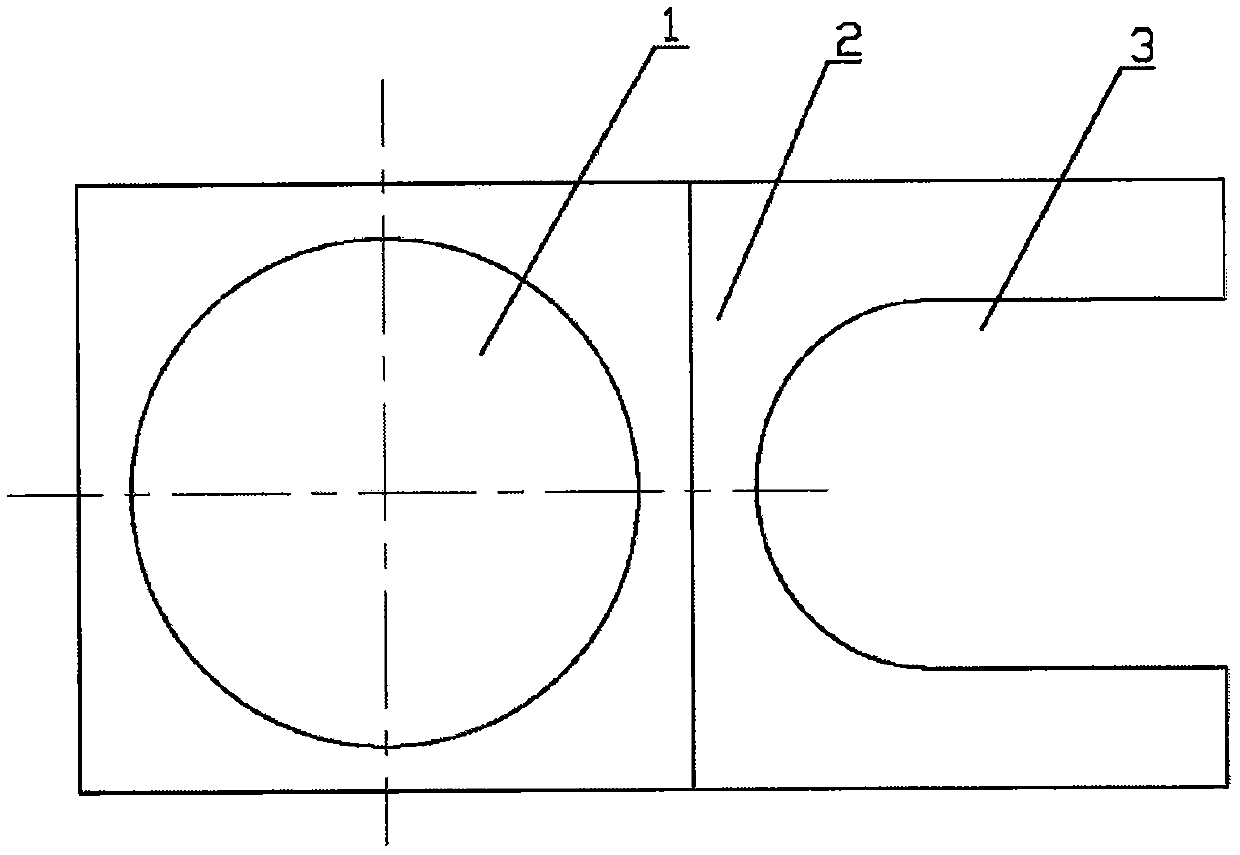

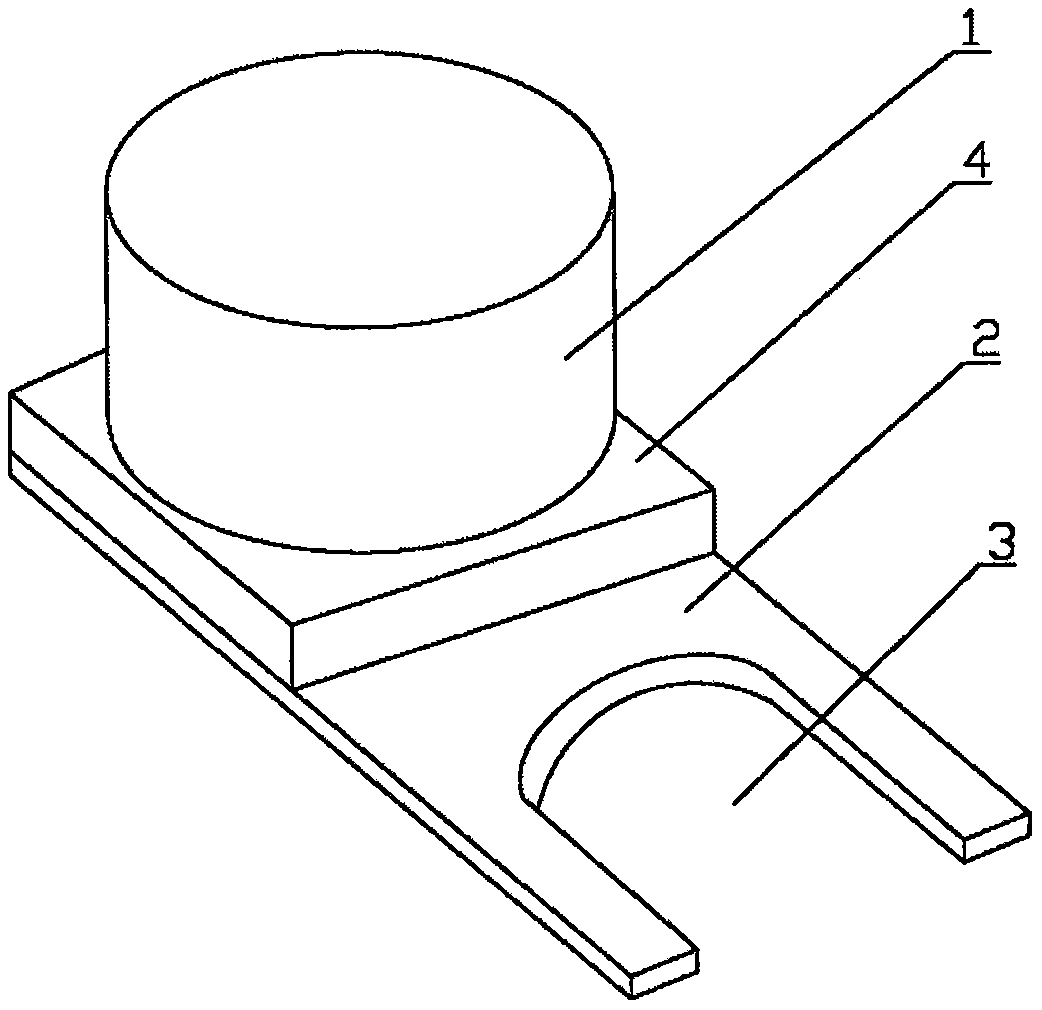

[0022] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of front, back, up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0023] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

[0024] as attached figure 1 , 2 , 3, the temperature monitoring sensor includes an insulating shell 1, a metal temperature sensing base plate 2, a surface acoustic wave temperature monitoring module and an antenna, a groove 3 is arranged at one end of the metal temperature sensing base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com