Axial compression slow descending device

An axial and slow-down technology, which is applied in building rescue and life-saving equipment, etc., can solve problems such as sudden change of static friction into sliding friction, reduction of load-bearing capacity of slow-down device, wear of ropes and pressing parts, etc., to achieve increased The effect of maximum static friction, reasonable fit, and strengthening mechanism strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

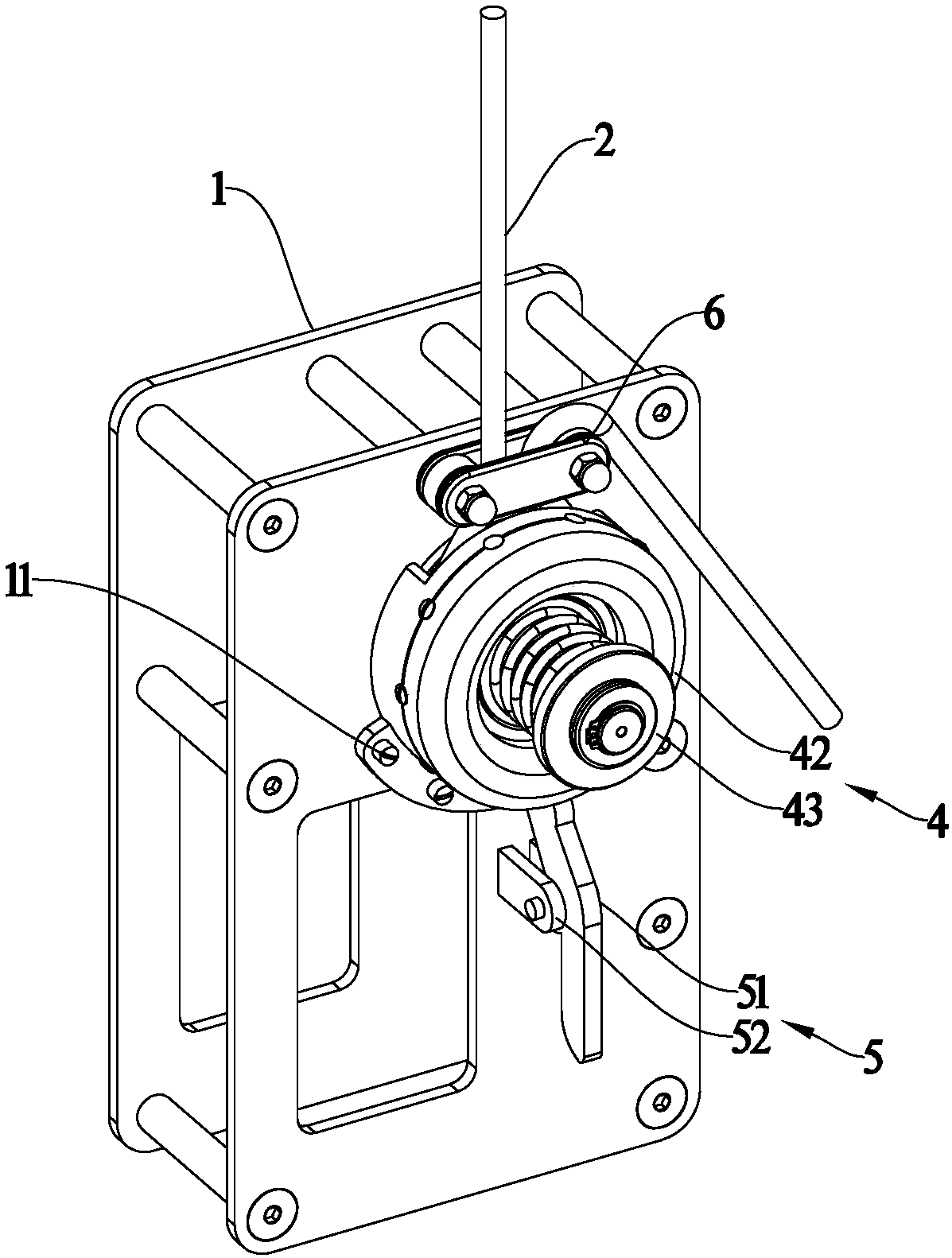

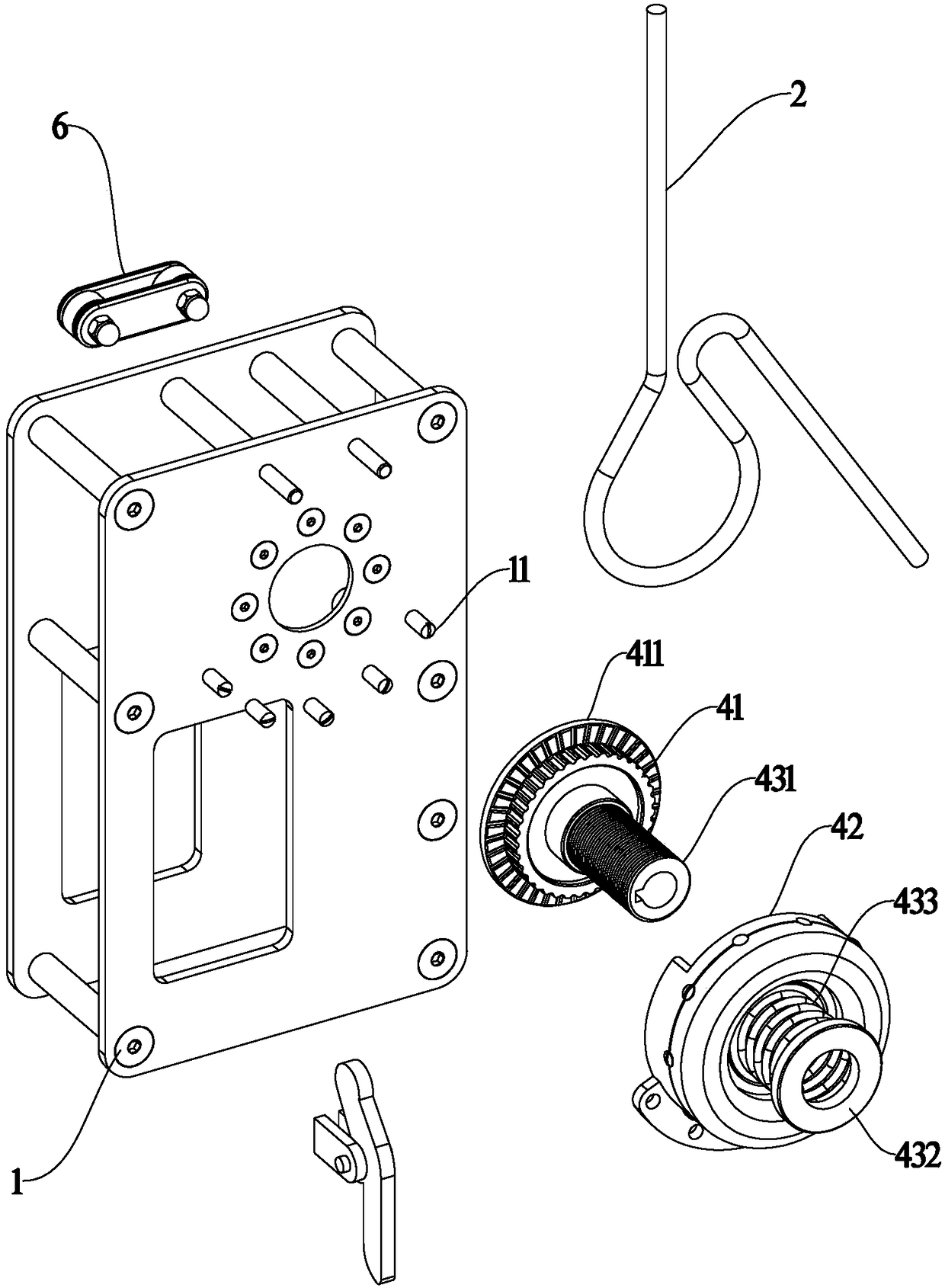

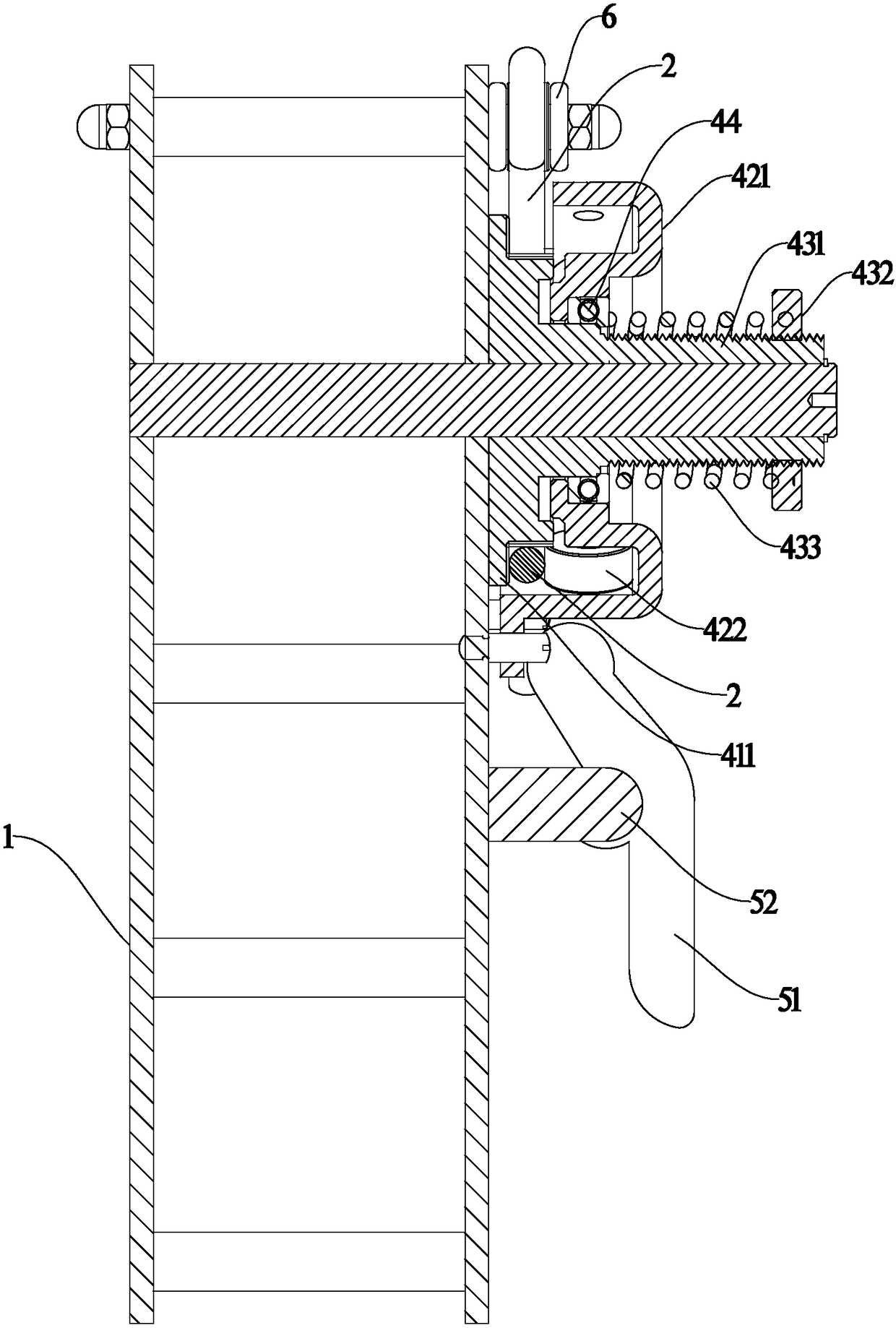

[0028] like Figure 1~6 As shown, a preferred embodiment of the present invention comprises frame 1, rope 2 and axial pressing mechanism 4, and rope 2 passes through axial pressing mechanism 4, and axial pressing mechanism 4 comprises rotating disk 41 and pressing member 42, the turntable 3 is rotatably installed on the frame 1, the bottom peripheral side of the turntable 41 extends out of the support platform 411, the rope 2 surrounds the periphery of the turntable 41 along the circumferential direction of the turntable 41 and is placed on the support platform 411, and the pressing member 42 It includes a pressing shell 421 and a pressing roller 422. The pressing roller 422 is rotatably arranged on the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com