Rapid on-site vertical lifting bed fence

A lifting bed and in-situ technology, which is applied in the direction of children's beds, children's furniture, household appliances, etc., can solve the problems of poor stability, inconvenient lifting bed fence, etc., and achieve the effect of safe lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

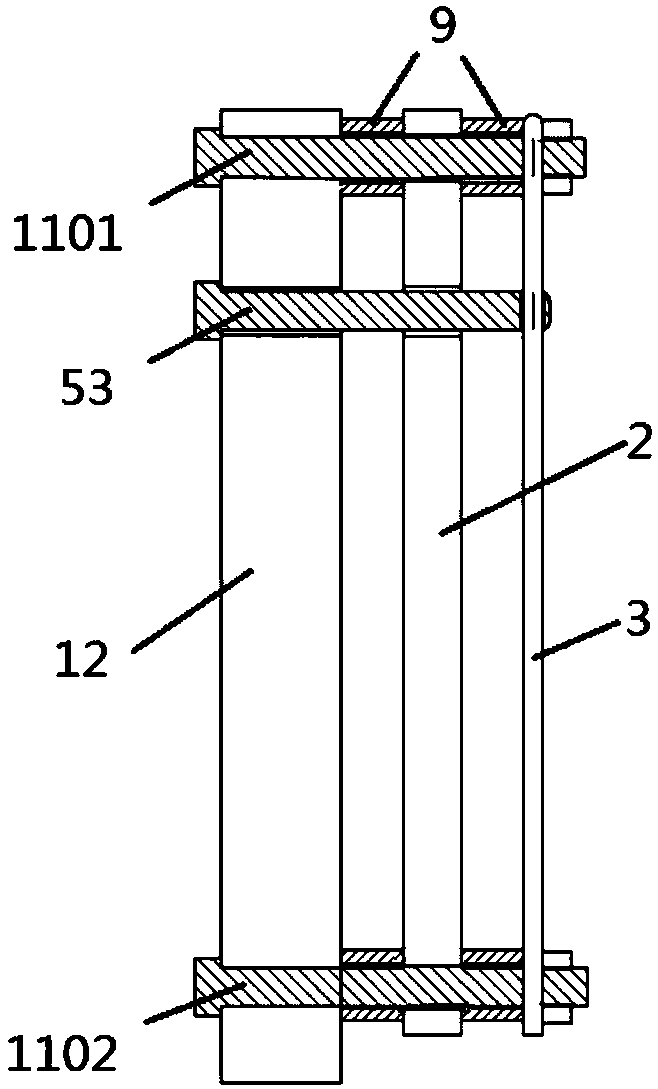

[0101] Such as Figure 13 Up to Embodiment 4 of the present invention shown in Figure 15, the description of the same part as Embodiment 1 in this embodiment is omitted below, and only the structure different from Embodiment 1 is described here;

[0102] The upper fixed rod 1101 and the lower fixed rod 1102 installed on the same column 12 have the same orientation, and each has two mounting holes for installing the main rod 2 and the secondary guide rod 3. The upper and lower ends are respectively installed on the upper fixed rod 1101 and the lower fixed rod 1102 through the mounting holes, and the diameters of the main rod 2 and the secondary guide rod 3 are the same; in this embodiment, no pad 9 is provided;

[0103] The manual switch device 4 includes a rotating handle 44, a rotating shaft and a handle return spring 411. The rotating handle 44 is installed outside the lifting rod 1 through a rotating shaft. On the straight face; the two ends of the handle return spring 411...

Embodiment 5

[0110] Such as Figure 14a and 14b In the illustrated embodiment 5 of the present invention, the description of the same part as the embodiment 4 in the present embodiment is omitted below, and only the structure different from the embodiment 4 is described here;

[0111] The transmission positioning device 6 comprises two steel wire sleeves 64 and two steel wires 63 installed in the two steel wire sleeves;

[0112] Manual switch device 4 comprises: No. 1 switch push rod 45e, slide rail 46, slide block 47, No. 1 switch push block 48e, No. 1 push block groove 49e and first switch housing 410e; Wherein, by upper rectangular half shell and The first switch casing 410e, which is composed of the upper and lower isosceles trapezoidal half shells in the lower part, is installed outside the lifting rod 1, and the left and right two steel wire sleeves 64 pass through the holes at the left and right ends of the first switch casing 410e, so that the two steel wires 63 can enter the firs...

Embodiment 6

[0118] Such as Figure 15a and 15b In the illustrated embodiment 6 of the present invention, the description of the same part as the embodiment 4 in the present embodiment is omitted below, and only the structure different from the embodiment 4 is described here;

[0119] The transmission positioning device 6 comprises two steel wire sleeves 64 and two steel wires 63 installed in the two steel wire sleeves;

[0120]Manual switch device 4 comprises: No. 2 switch push rod 45f, No. 2 switch push block 48f, No. 2 push block groove 49f and second switch shell 410f; The second switch housing 410f is installed outside the lifting rod 1, and the left and right two steel wire sleeves 64 pass through the holes at the left and right ends of the second switch housing 410f, so that the two steel wires 63 can enter the second switch housing 410f; the second switch housing 410f There is No. 2 push block groove 49f in the bottom surface along the symmetrical axis. No. 2 switch push block 48...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com