Installation structure of hanging type roof plate

A technology for installing structure and roof, applied in the direction of ceiling, building components, building structure, etc., can solve the problems of low installation accuracy, difficult to adjust welding and fixing, difficult to master, etc., to achieve convenient maintenance and upgrading, high installation flexibility, The effect of improving technical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

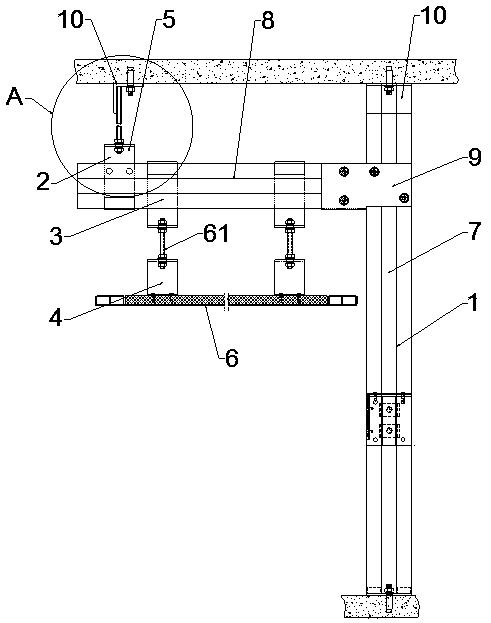

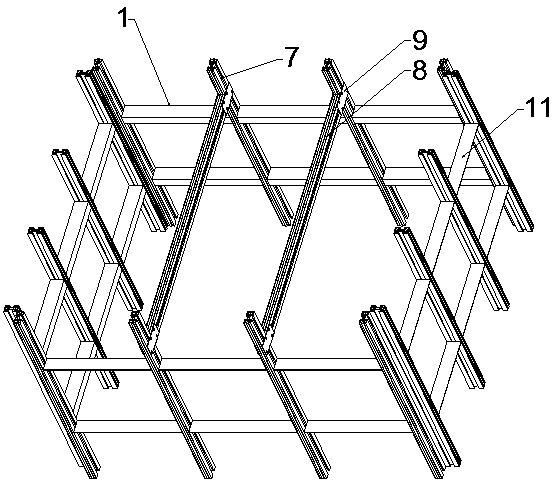

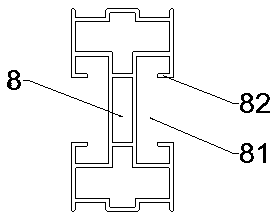

[0022] A hanging roof installation structure, comprising an integral keel frame 1, a roof keel hook 2, a roof hook 3, a roof hanger 4, a hanging component 5 and a hanging roof 6, the overall keel frame 1 includes a wall keel 7, a roof keel 8 and The keel connector 9 between the two is fixed, and the crosspiece 11 is also connected between the wall keels 7. The upper end of the wall keel 7 is connected and fixed with an angle steel 10, and the angle steel 10 is fixed on the top surface of the building by expansion bolts. The side wall of the wall keel 7 is provided with mounting holes, the keel connector 9 is connected in the installation hole of the wall keel 7 by bolts and nuts, the top keel 8 is put into the groove of the keel connector 9, and is fastened by bolts and nuts. On the keel connector 9, the upper end of the top keel 8 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com