Airlock device of aluminum melt degasification tank and degasification tank

A technology of aluminum melt and air lock, which is applied in the field of degassing box, can solve the problems of reducing the effect of degassing, lowering the temperature of furnace chamber, affecting product quality, etc., achieving stability maintenance, large sealing contact area, and simple outer contour Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

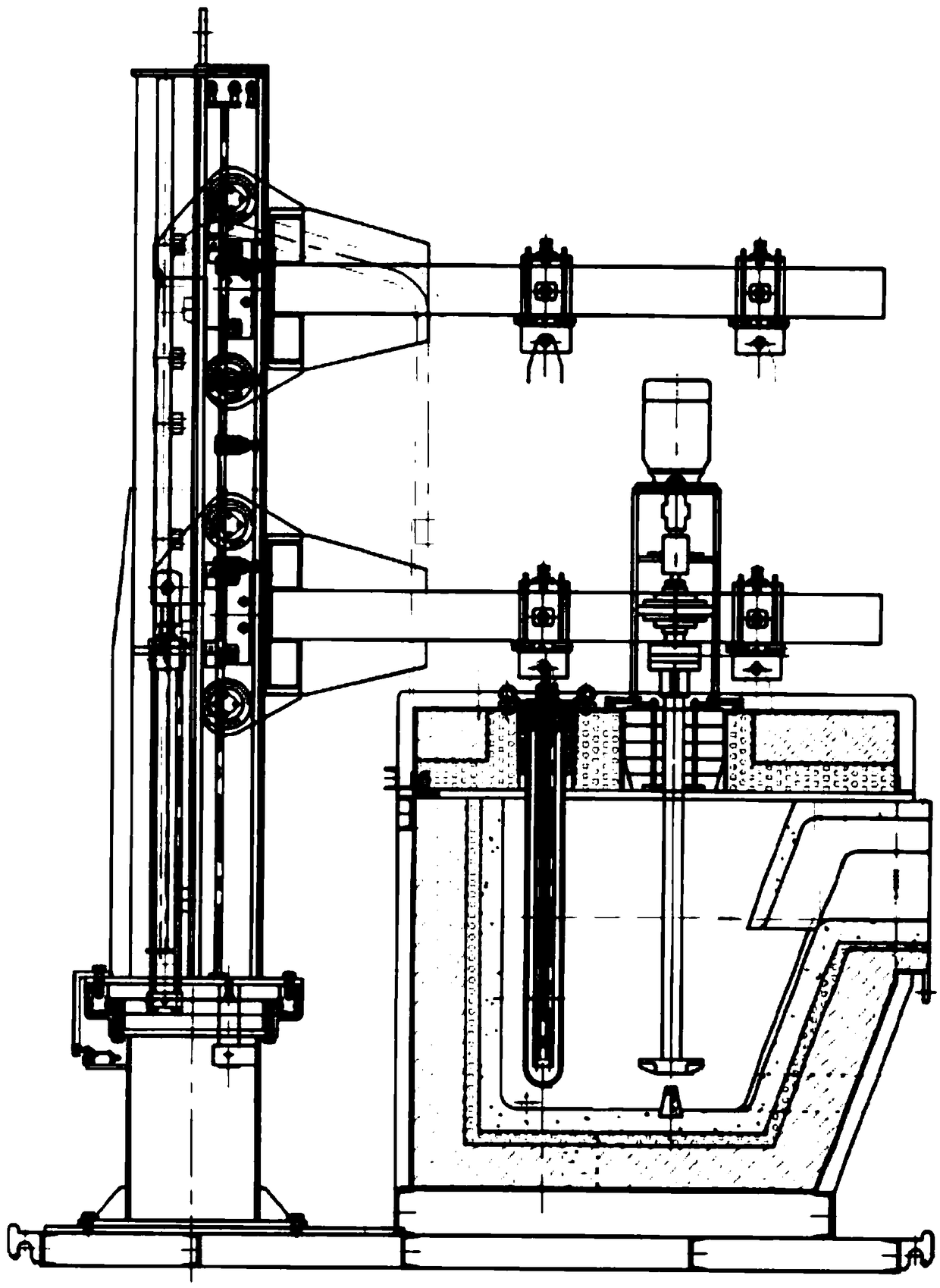

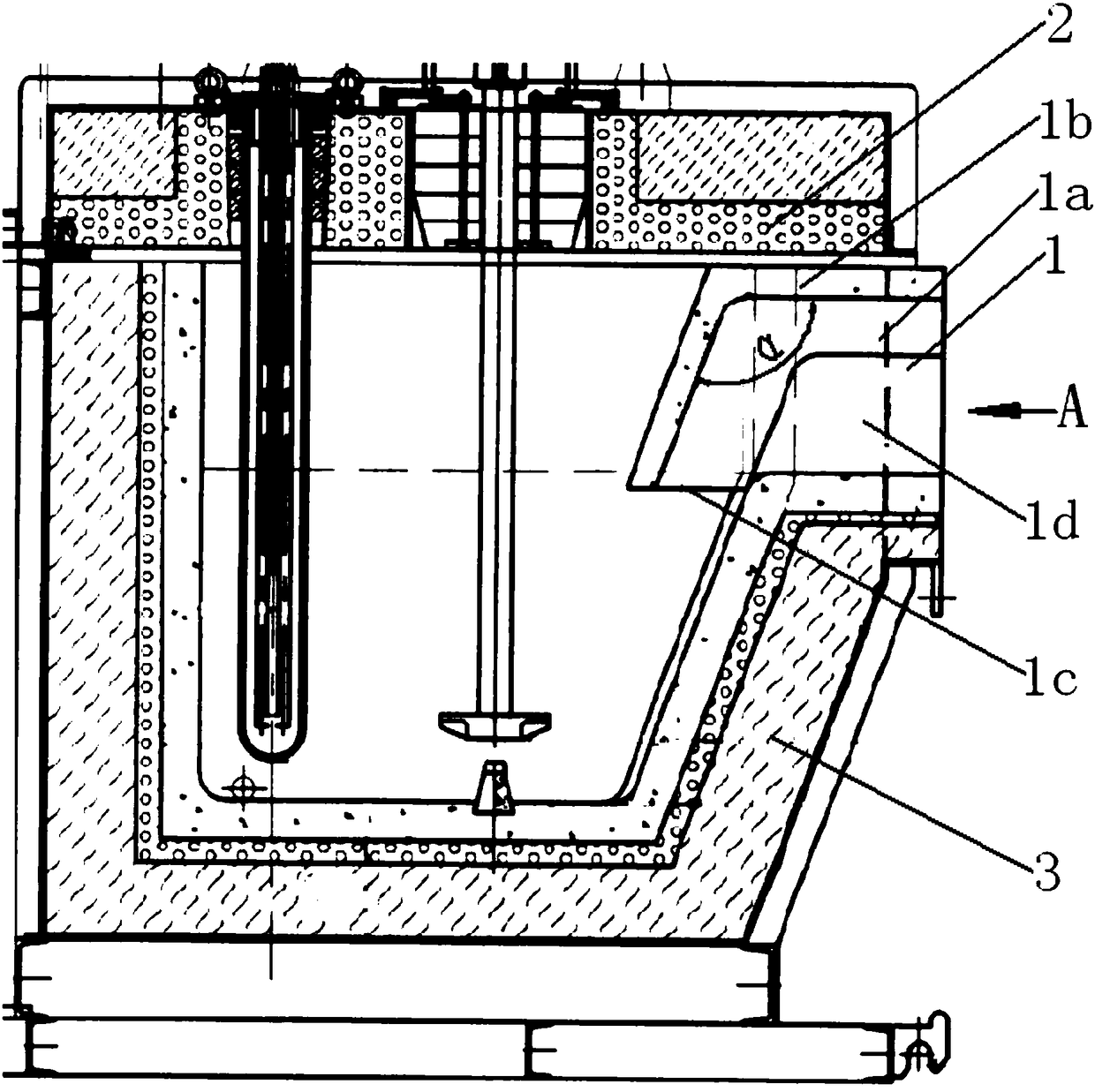

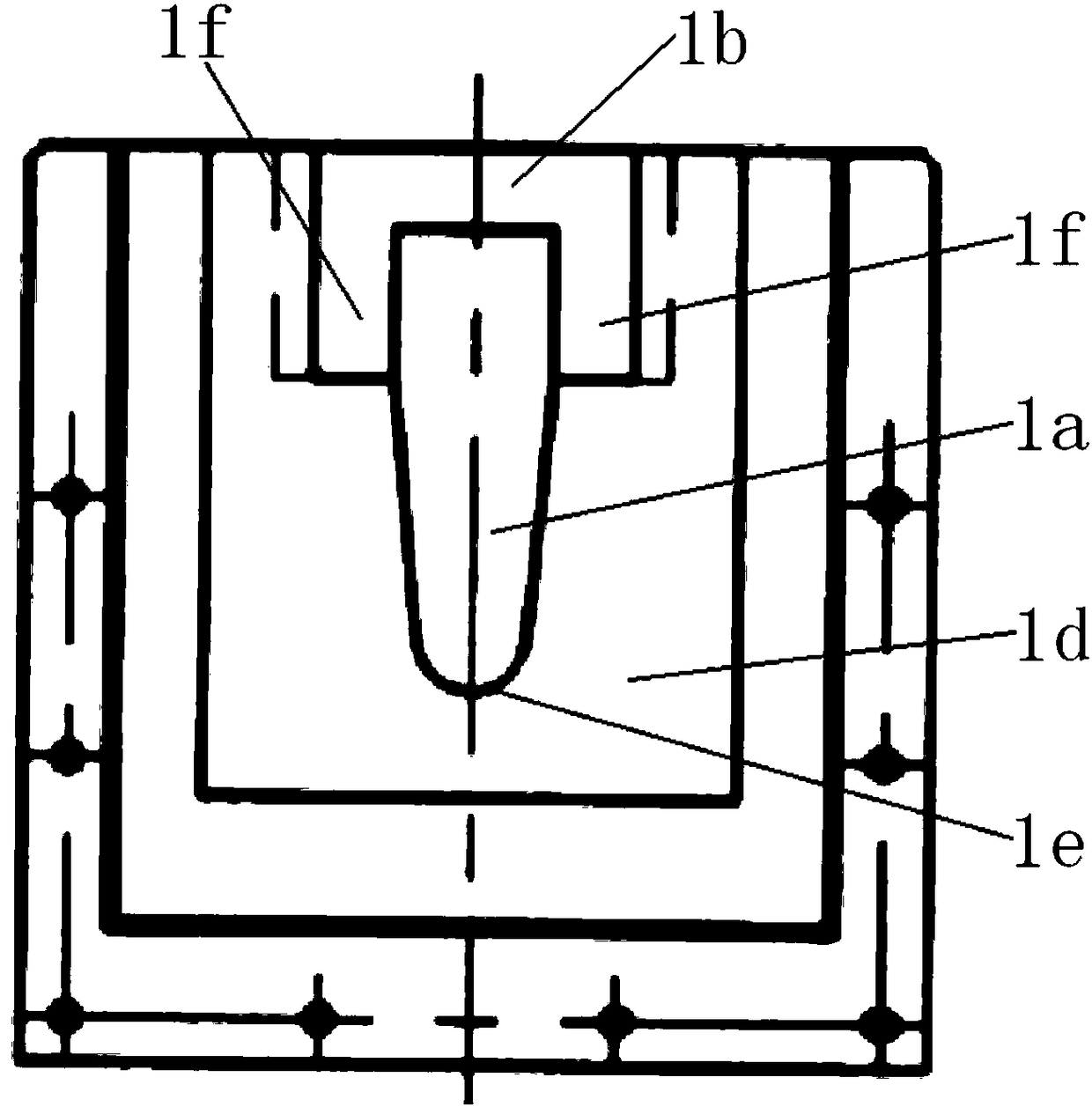

[0031] In order to achieve the purpose of the present invention, an air lock device for an aluminum melt degassing box includes: an air lock 1, the air lock 1 is composed of a partition wall 1b, an upper channel 1a, and an aluminum inlet chamber 1d; the partition wall 1b is located in the box The boundary between the cover 2 and the box body 3 is composed of a horizontal wall 1ba and an inclined wall 1bb; the upper channel 1a is arranged in parallel in the inner space formed by the partition wall 1b, and the upper channel 1a extends along the partition wall 1b, and the upper channel 1a is at the lowest point It has a horizontal lower port 1c, and the lower port 1c is inserted below the liquid level 5 in the tank 3; the aluminum inlet chamber 1d communicates with the upper channel 1a by means of a communication port, and the height of the communication port is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com