Rotor vertical fixing device and rotor vertical fixing method

A fixing method and a technology of a fixing device, which are applied in the direction of adjusting/balancing the rotor, etc., can solve problems such as easily damaged bearing inner rings and bearing stop fitting surfaces, affecting bearing assembly quality, scrapping of bearings and rotating shafts, etc., and achieve simple structure and improved Reliability and accuracy, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

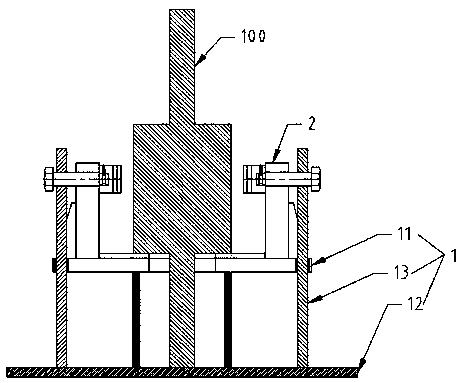

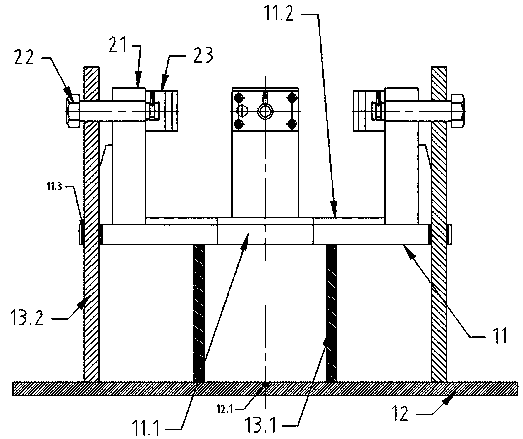

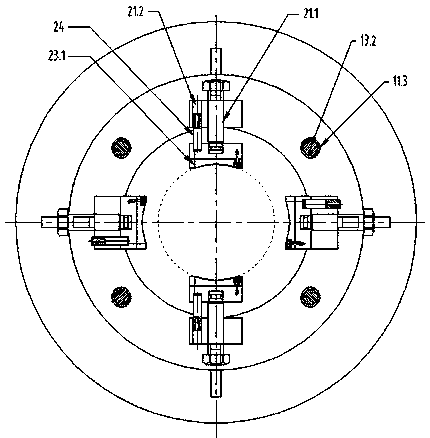

[0030] Attached below Figure 1~3 Embodiments of the present invention are described in detail.

[0031] The rotor vertical fixing device includes a support table 1 and a clamping assembly 2 arranged on the support table 1. The rotor 100 stands on the support table 1, and the clamping assembly 2 clamps the rotor 100. It is characterized in that the support table 1 includes an upper support plate 11 for supporting the weight of the rotor 100, a bottom plate 12 located directly below the upper support plate 11 and having a larger area than the upper support plate 11, and a support adjustment assembly 13 that can drive the upper support plate 11 to move up and down, the support adjustment assembly 13 Fixed on the base plate 12 to support the upper support plate 11, the center of the upper support plate 11 has a through hole 11.1 with a diameter smaller than the maximum diameter of the rotor 100, the rotating shaft of the rotor 100 passes through the through hole 11.1, and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com