Method for producing high voltage and high energy of single battery, preparation method and production method of battery pack

A single battery, high-energy technology, applied in the direction of secondary battery manufacturing, battery pack components, electrolyte storage battery manufacturing, etc., can solve the problem of large battery packs, etc., to achieve the effect of increasing the voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

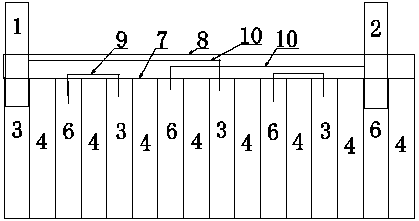

Image

Examples

Embodiment 1

[0043] The preparation method of the plate-type battery pack of the present embodiment comprises the following preparation steps:

[0044] a) Preparation of positive electrode: 95.5% nickel-cobalt lithium manganese oxide (LiNixCoyMn(1-x-y)O2, where x=1 / 5~4 / 5, y=1 / 5~4 / 5) was used as solvent in NMP , 1.6% of conductive carbon, 1.0% of BP-2000 and 2% of polyvinylidene fluoride were mixed and stirred to form the active material layer A slurry, the solid content of the active material layer A slurry was 65%, and 16 μm aluminum foil was used as the positive electrode collector Fluid, and then apply the active material layer slurry on the surface of 16μm aluminum foil to form the active material layer, dry, and then use a roller press to compact the pole piece to make a positive pole piece, and then use a punching machine or film cutting The machine made the large sheet into a positive electrode sheet of a specified size with an aluminum foil current collector.

[0045] b) Preparati...

Embodiment 2

[0050] The preparation method of the plate-type battery pack of the present embodiment comprises the following preparation steps:

[0051] a) Preparation of positive electrode: 95.5% nickel-cobalt lithium manganese oxide (LiNixCoyMn(1-x-y)O2, where x=1 / 5~4 / 5, y=1 / 5~4 / 5) was used as solvent in NMP , 1.6% of conductive carbon, 1.0% of BP-2000 and 2% of polyvinylidene fluoride were mixed and stirred to form the active material layer A slurry, the solid content of the active material layer A slurry was 65%, and 16 μm aluminum foil was used as the positive electrode collector Fluid, and then apply the active material layer slurry on the surface of 16μm aluminum foil to form the active material layer, dry, and then use a roller press to compact the pole piece to make a positive pole piece, and then use a punching machine or film cutting The machine made the large sheet into a positive electrode sheet of a specified size with an aluminum foil current collector.

[0052] b) Preparati...

Embodiment 3

[0057] The preparation method of the plate-type battery pack of the present embodiment comprises the following preparation steps:

[0058] a) Preparation of positive electrode: 95.5% nickel-cobalt lithium manganese oxide (LiNixCoyMn(1-x-y)O2, where x=1 / 5~4 / 5, y=1 / 5~4 / 5) was used as solvent in NMP , 1.6% of conductive carbon, 1.0% of BP-2000 and 2% of polyvinylidene fluoride were mixed and stirred to form the active material layer A slurry, the solid content of the active material layer A slurry was 65%, and 16 μm aluminum foil was used as the positive electrode collector Fluid, and then apply the active material layer slurry on the surface of 16μm aluminum foil to form the active material layer, dry, and then use a roller press to compact the pole piece to make a positive pole piece, and then use a punching machine or film cutting The machine made the large sheet into a positive electrode sheet of a specified size with an aluminum foil current collector.

[0059] b) Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com