Method for measuring cyanide in cyanidation tailing slurry

A determination method and cyanide technology, applied in the field of monitoring, can solve the problems of large measurement error, unsuitable soil measurement method, and many interference factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

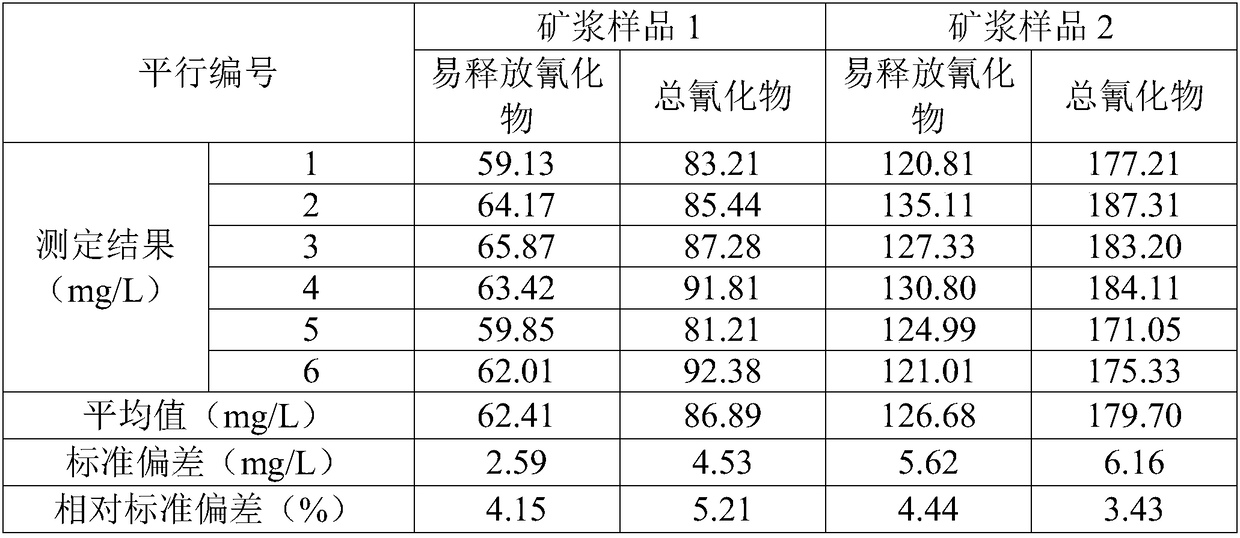

[0031] Take the cyanide tailings slurry of two different gold production enterprises, that is, the pulp sample 1 of one company and the pulp sample 2 of another company, and the pulp sample 1 and the pulp sample 2 of the two companies respectively take six 200mL cyanide tailings pulp , according to the above method for parallel testing, and calculate the standard deviation and relative standard deviation, the results are shown in Table 1:

[0032] Table 1 The accuracy test data of this method

[0033]

[0034] As can be seen from the test results in Table 1, the relative standard deviations of the easy-release cyanide determination of this method are 4.15% and 4.44%, and the relative standard deviations of the total cyanide determination are 5.21% and 3.43%.

Embodiment 2

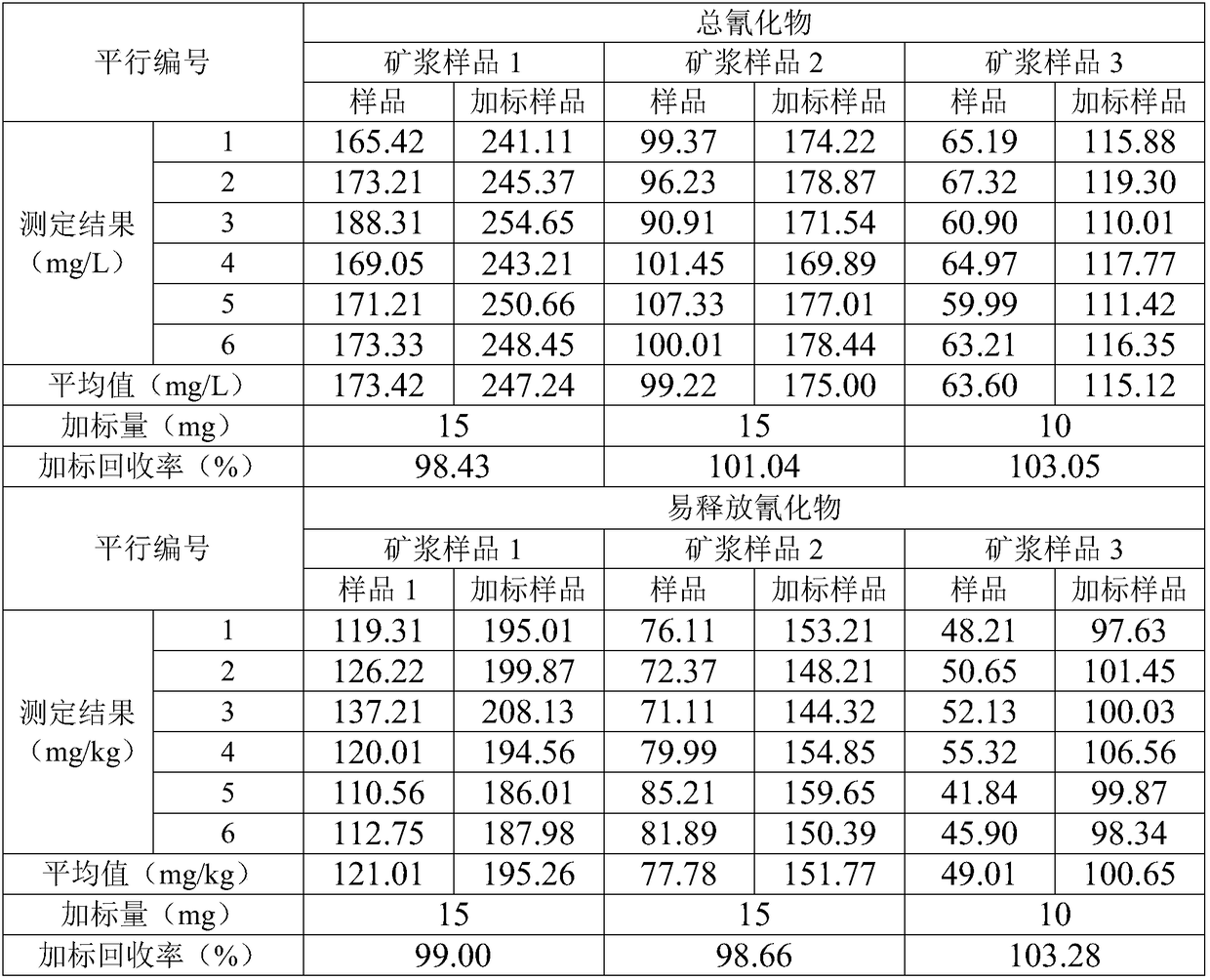

[0036] The cyanide tailings pulp of three different gold production enterprises was taken, that is, the pulp sample 1 of one company, the pulp sample 2 of one company, and the pulp sample 3 of another company, and the pulp sample 1, pulp sample 2 and pulp sample 3 of the three companies were respectively Take 6 parts of 400mL cyanide tailings slurry, and each part of 400mL cyanide tailings slurry is divided into two parts, one of which is tested according to the requirements of the above method, and the other part is added to the standard solution of easy-release cyanide and then carried out according to the above method Determination and calculation of standard addition recovery;

[0037] The cyanide tailings pulp of three different gold production enterprises was taken, that is, the pulp sample 1 of one company, the pulp sample 2 of one company, and the pulp sample 3 of another company, and the pulp sample 1, pulp sample 2 and pulp sample 3 of the three companies were respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com