Arc clamping piece applied to one-way valve body

A technology of one-way valve and card, which is applied in the direction of control valve, valve device, function valve type, etc., and can solve problems such as loss of performance and card falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

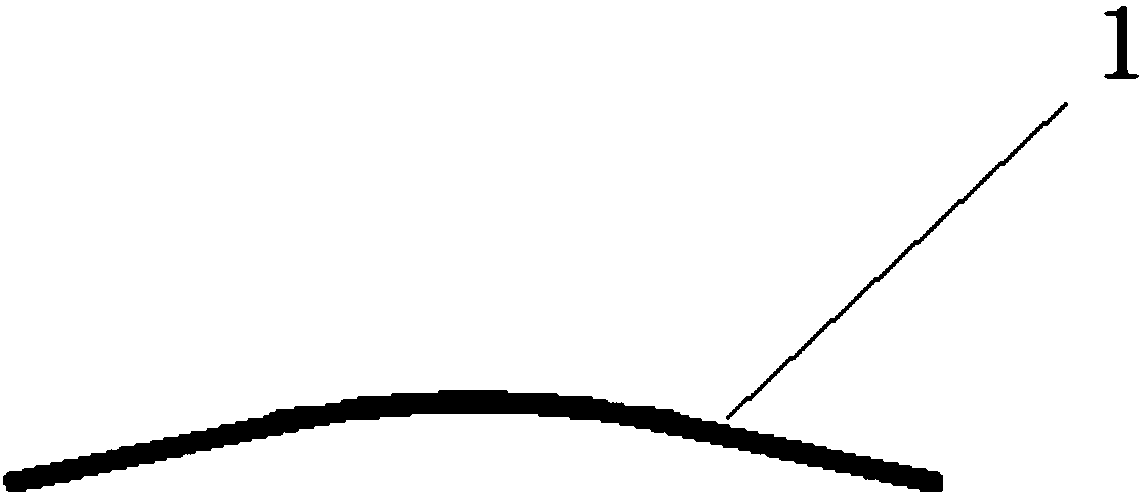

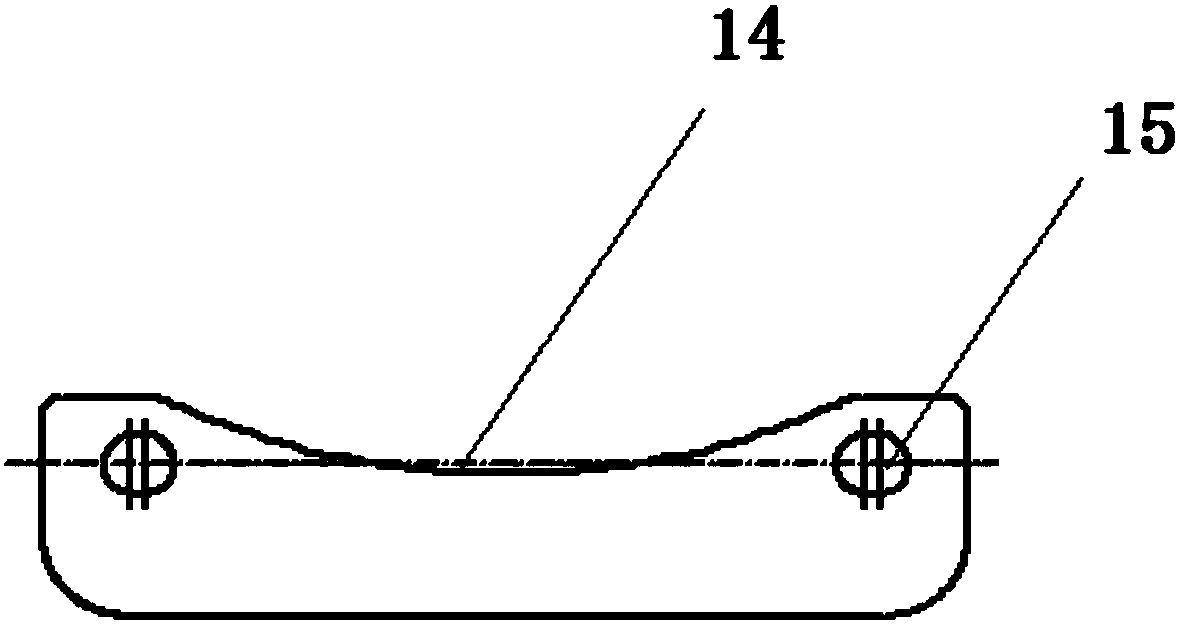

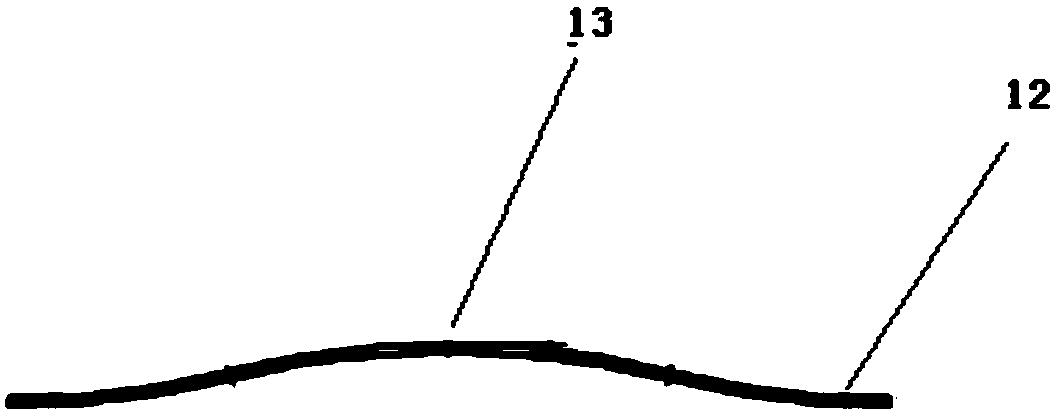

[0015] The arc-shaped card applied to the one-way valve body in this embodiment is installed on the annular valve plate of the one-way valve body, and the arc-shaped card is a thin sheet 1 with a curvature. Both ends of the card are provided with mounting holes 15, and one side of the sheet is an arc-shaped side 14 bent inward.

[0016] The radius of curvature corresponding to the arc where the sheet 1 is located in this embodiment is 50 mm, and the arc height is 4.68 mm. The arc of the arc edge 14 is 43.5 mm, and the height of the arc edge is 4 mm. Cards are made of 65Mn. When installing the thin slice to the annular valve plate, first press the arched part of the thin slice to keep the thin slice in a flat state, and then align the mounting holes 15 at both ends of the thin slice with the pins on the annular valve slice before installing. After being installed in place, due to the elasticity of the 65Mn material, the sheet will naturally arch. The distance between the two...

Embodiment 2

[0018] The arc-shaped card applied to the one-way valve body in this embodiment is installed on the annular valve plate of the one-way valve body, and the arc-shaped card is a thin sheet 1 with a curvature. Both ends of the card are provided with mounting holes 15, and one side of the sheet is an arc-shaped side 14 bent inward.

[0019] The radius of curvature corresponding to the arc of the sheet 1 in this embodiment is 50.1 mm, and the height of the arc is 4.70 mm. The radian of the arc edge 14 is 43.4mm, and the height of the arc edge is 3.95mm. Cards are made of 65Mn.

Embodiment 3

[0021] The arc-shaped card applied to the one-way valve body in this embodiment is installed on the annular valve plate of the one-way valve body, and the arc-shaped card is a thin sheet 1 with a curvature. Both ends of the card are provided with mounting holes 15, and one side of the sheet is an arc-shaped side 14 bent inward.

[0022] The radius of curvature corresponding to the arc of the sheet 1 in this embodiment is 49.9 mm, and the height of the arc is 4.66 mm. The arc of the arc edge 14 is 43.6 mm, and the height of the arc edge is 4.05 mm. Cards are made of 65Mn.

[0023] The arc-shaped cards applied to the one-way valve body in the above three embodiments are made of elastic materials, and the distance between the installation holes at both ends of the arc-shaped card can be adjusted through elastic deformation. Apply external force to make the hole distance larger to complete the installation; remove the external force after installation to make the hole distance s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com