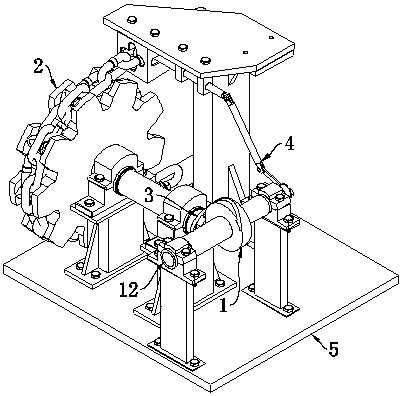

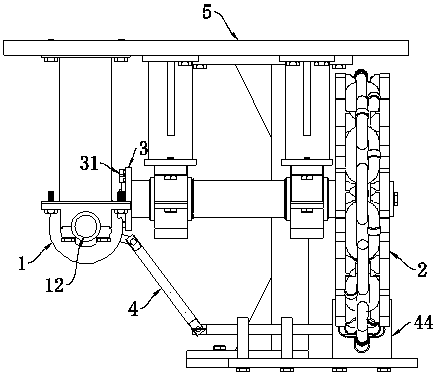

Pass type skip-plating and chain-separating preventing device for circular ring chain continuous hot-dip coating

A round link chain, hot-dip plating technology, applied in hot-dip plating process, transmission device, belt/chain/gear, etc., can solve the problem of difficulty in fully immersing in the joints of chain links, high viscosity of plating solution, poor fluidity, etc. Problems, to achieve the effect of eliminating missing plating, compact structure, and easy equipment maintenance and overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

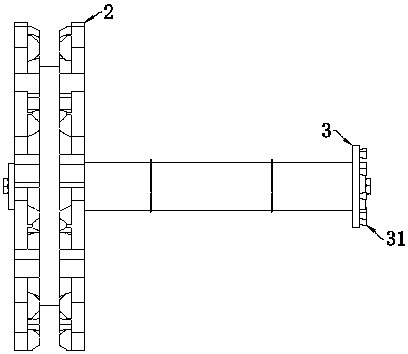

[0039] For zinc-nickel-plating type hot-dip plating operations, due to the relatively poor viscosity of the plating solution and good fluidity, the phase angle of the static section 112 of the profile 11 can be designed to be a quarter cycle or less, and the reverse section 111 The phase angle with the forward rotation section 113 can be appropriately increased to reduce the impact and noise of the device. The forward rotation section 113 is designed so that the angle at the entry end is greater than the angle at the exit end.

Embodiment 3

[0041] For chrome plating or hard chrome plating or diamond plating and other high viscosity hot-dip plating operations, in order to fully immerse the plating solution into the gap of the circular link chain, the phase angle of the static section 112 of the profile line 11 can be designed to be half a cycle And above, so as to ensure that the plating solution has sufficient immersion time, and to a greater extent eliminate the phenomenon of missing plating in the gaps of the circular chain.

[0042] The present invention realizes the through-type ring chain continuous hot-dip coating device by adopting means such as mechanical transmission and mechanism design. It can be easily replaced so that the molding line can adapt to the needs of different viscous plating solutions. At the same time, under the premise of improving the efficiency of the hot-dip plating operation of the circular link chain, it can also obviously prevent the phenomenon of missing plating at the joints of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com