Non-combustible phase change thermal thruster

A technology of phase-change heat and thrust devices, which is applied in the field of power engineering and can solve problems such as environmental pollution, long industrial production chains, and environmental pollution from gunpowder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

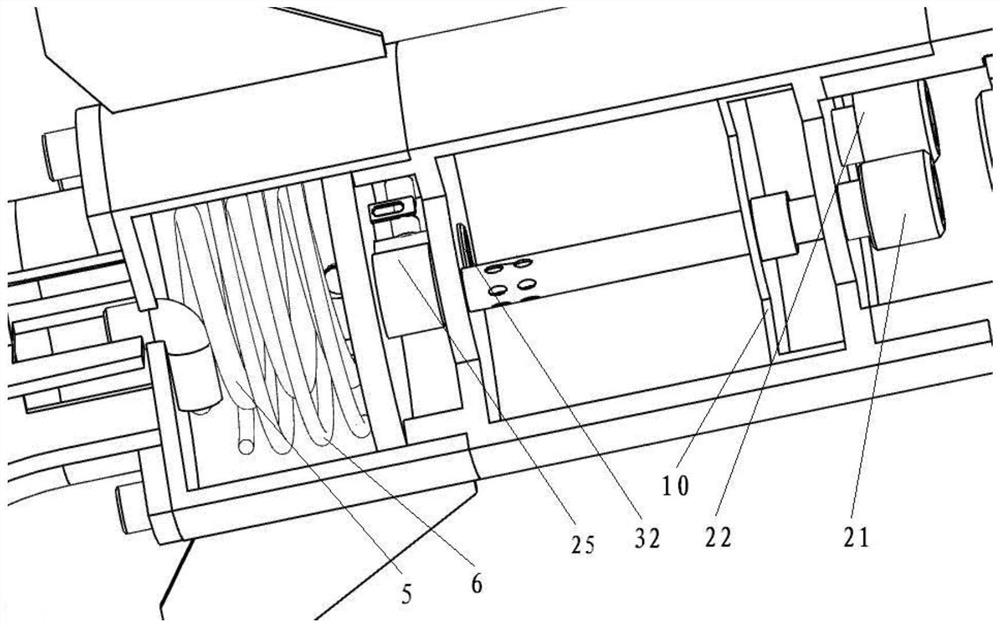

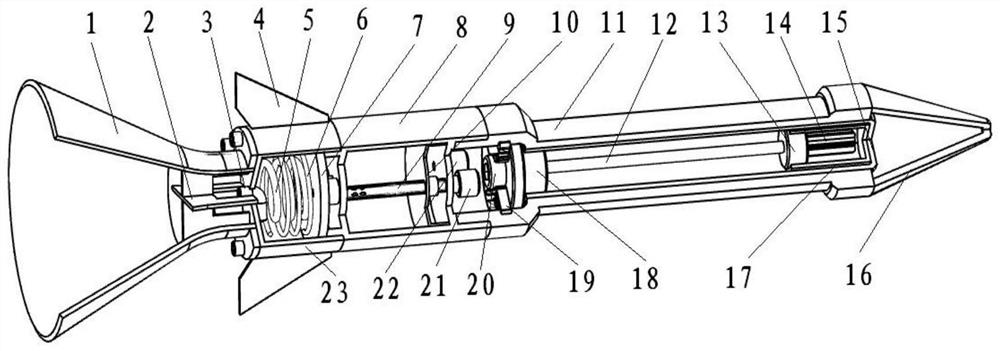

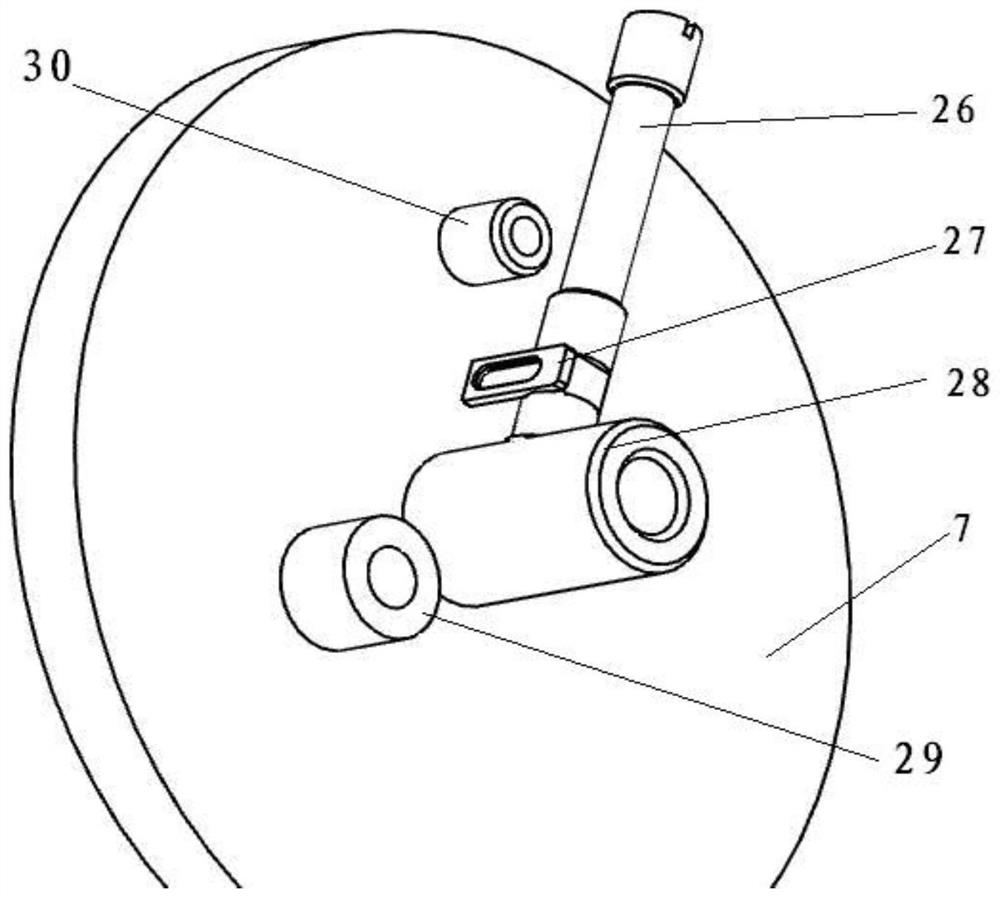

[0045] Such as Figure 1 to Figure 6 As shown, this embodiment includes a nozzle 1, a deflector 2, a spout 3, a tail rudder 4, a spiral tube 5, an electric heating tube 6, a plugging cover 7, a cold cabin 8, a liquid injection pipe 9, a piston 10, and a load cabin 11 , detonator 12, timing device 13, explosive 14, storage cylinder 15, head cover 16, profile 17, tail block 18, retaining ring 19, first screw plug 20, second screw plug 21, third screw plug 22, heat Cabin 23, throttle valve 25, throttle rod 26, reed 27, outlet pipe 28, nozzle 29, electric heating joint 30, sealing ring 31, liquid outlet 32; Figure 4 The feature A of the middle throttle rod is the throttle port A, the feature B is the positioning ring B, and the feature C is the open groove C.

[0046] The nozzle 1 and the hot cabin 23 are connected by anti-loosening screws, the deflector 2 is fixedly connected with the nozzle 1; The load compartment 11 is fixedly connected, and the load compartment 11 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com