Ventilating and pumping device for crankcase

A crankcase ventilation and crankcase technology, which is applied to crankcase ventilation, charging system, adding non-fuel substances to fuel, etc., can solve problems such as air flow rate affecting the opening angle of the throttle valve, low oil replacement efficiency, and no cleaning effect. , to achieve the effect of improving oil replacement efficiency, good atomization effect and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

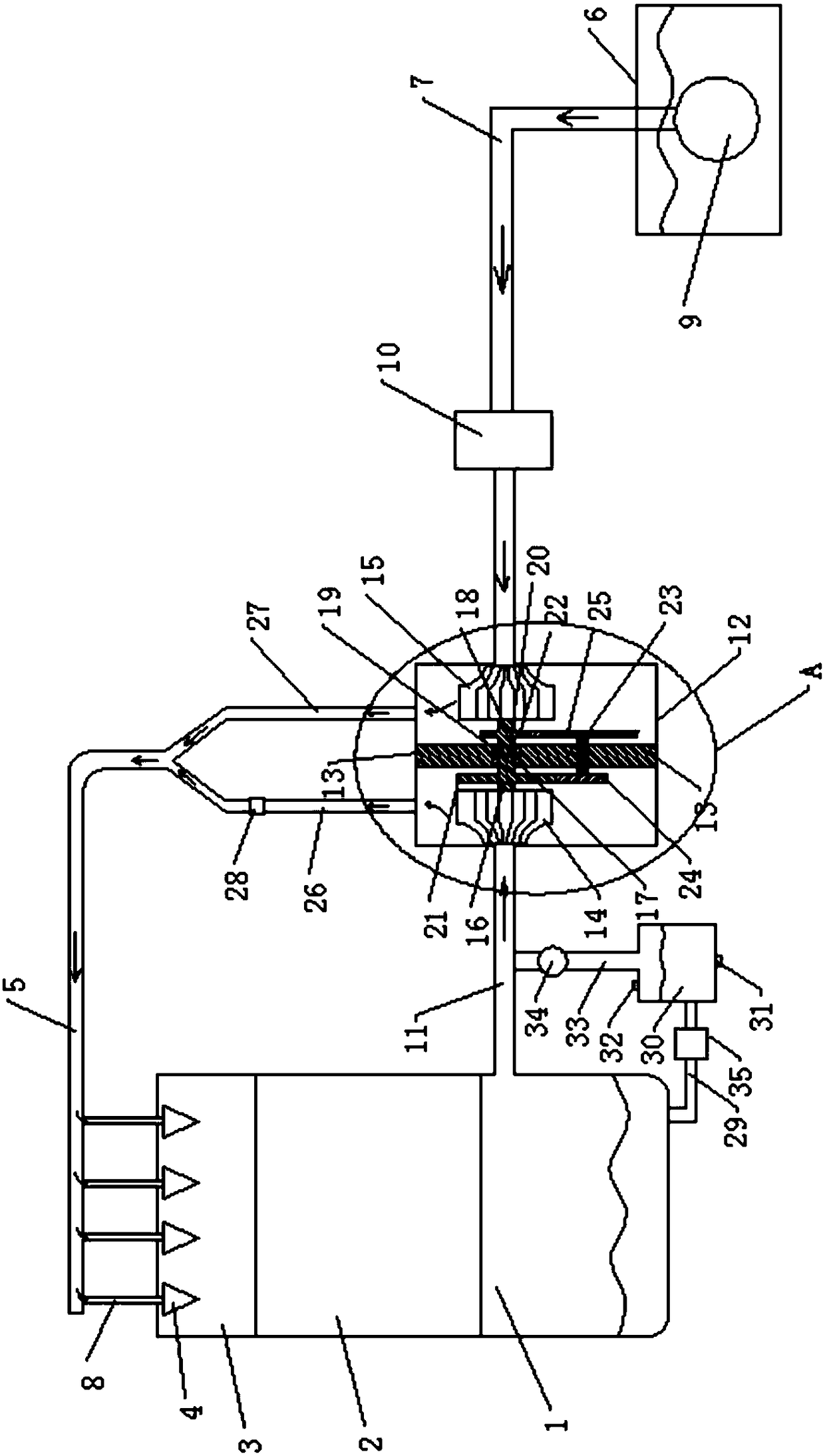

[0023] This embodiment proposes a crankcase ventilation and pumping device, such as figure 1 , 2 , 3, it includes crankcase 1, cylinder block 2, cylinder head 3, fuel injector 4, high-pressure fuel rail 5, fuel tank 6 and fuel delivery pipe 7, and high-pressure fuel rail 5 connects with corresponding cylinders through each connecting branch pipe 8 The fuel injector 4 is sealed and communicated. The fuel injector 4 is installed in the cylinder head 3, and its nozzle extends into the combustion chamber of the cylinder block 2. The cylinder head 3 is installed in the upper part of the cylinder block 2, and the lower part of the cylinder block 2 is installed There is a crankcase 1, the lower end of the oil delivery pipe 7 is in sealing communication with the outlet of the oil pump 9 in the fuel tank 6, the oil delivery pipe 7 is equipped with a pressurizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com