A formaldehyde-free non-ironing and wrinkle-resistant finishing process for real silk fabrics

A silk fabric, anti-wrinkle finishing technology, applied in the direction of animal fiber, fiber treatment, textile and papermaking, etc., can solve the problems of complicated finishing process, decreased strength of finishing fabric, easy yellowing, etc., and achieves simple and reliable process, full washability. , the effect of good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A formaldehyde-free non-ironing anti-wrinkle finishing process for real silk fabrics, comprising the following steps:

[0030] 1) Put the real silk fabric 11209 electric spinning into the pre-shrinking machine for pre-shrinking finishing, and the pre-shrinking rate of the pre-shrinking finishing is 3%.

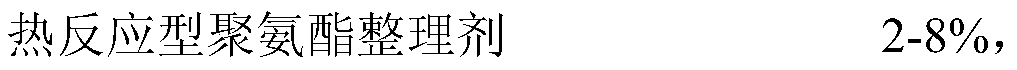

[0031] 2) Polyurethane-organic silicon non-ironing anti-wrinkle finishing solution is composed of the following components in mass percentage:

[0032]

[0033] The configuration of the polyurethane-organic silicon non-iron anti-wrinkle finishing solution: uniformly mix the above-mentioned several reagents according to the stated ratio to obtain the polyurethane-organic silicon non-iron anti-wrinkle finishing solution.

[0034] 3) The polyurethane-organic silicon non-ironing anti-wrinkle finishing liquid is uniformly entered into the silk fabric through the padding process, the padding process is two dipping and two rolling, and the excess rate is 70%;

[0035] 4) A...

Embodiment 2

[0038] A formaldehyde-free non-ironing anti-wrinkle finishing process for real silk fabrics, comprising the following steps:

[0039] 1) Put the real silk fabric 11209 electric spinning into the pre-shrinking machine for pre-shrinking finishing, and the pre-shrinking rate of the pre-shrinking finishing is 3%.

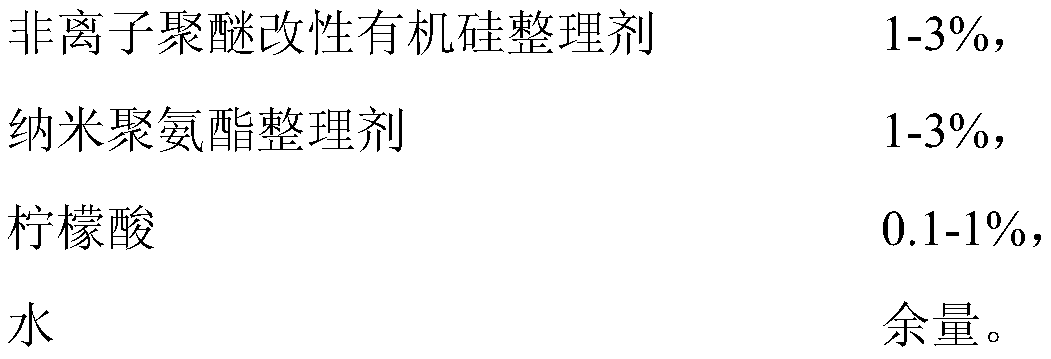

[0040] 2) Polyurethane-organic silicon non-ironing anti-wrinkle finishing solution is composed of the following components in mass percentage:

[0041]

[0042] The configuration of the polyurethane-organic silicon non-iron anti-wrinkle finishing solution: uniformly mix the above-mentioned several reagents according to the stated ratio to obtain the polyurethane-organic silicon non-iron anti-wrinkle finishing solution.

[0043] 3) The polyurethane-organic silicon non-ironing anti-wrinkle finishing liquid is uniformly entered into the silk fabric through the padding process, the padding process is two dipping and two rolling, and the excess rate is 70%;

[0044] 4) A...

Embodiment 3

[0047] A formaldehyde-free non-ironing anti-wrinkle finishing process for real silk fabrics, comprising the following steps:

[0048] 1) Put the real silk fabric 11209 electric spinning into the pre-shrinking machine for pre-shrinking finishing, and the pre-shrinking rate of the pre-shrinking finishing is 3%.

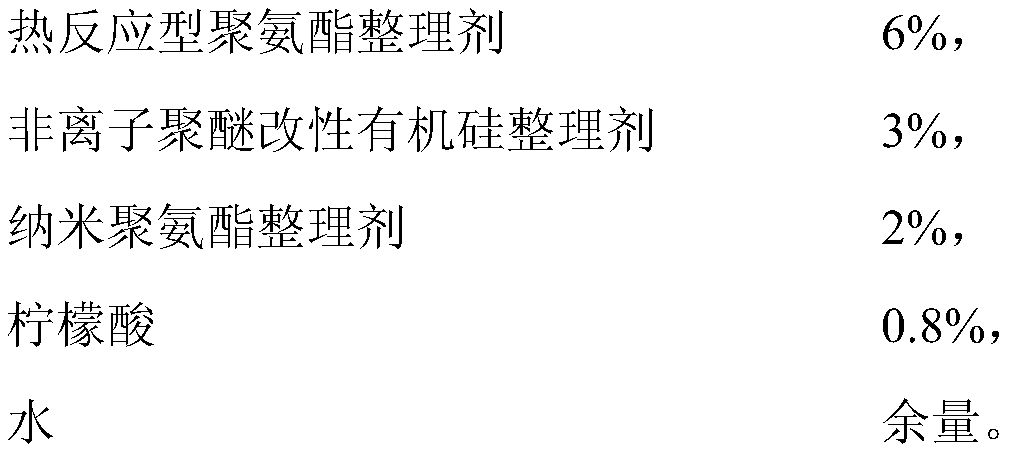

[0049] 2) Polyurethane-organic silicon non-ironing anti-wrinkle finishing solution is composed of the following components in mass percentage:

[0050]

[0051]

[0052] The configuration of the polyurethane-organic silicon non-iron anti-wrinkle finishing solution: uniformly mix the above-mentioned several reagents according to the stated ratio to obtain the polyurethane-organic silicon non-iron anti-wrinkle finishing solution.

[0053] 3) The polyurethane-organic silicon non-ironing anti-wrinkle finishing liquid is uniformly entered into the silk fabric through the padding process, the padding process is two dipping and two rolling, and the excess rate is 70%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com