Method for optimizing grain boundary characteristic distribution of 316L austenitic stainless steel

A technology of austenitic stainless steel and characteristic distribution, which is applied in the field of materials, can solve problems such as limiting the application range of the technology, achieve a significant increase in the range, and improve the effect of intergranular corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

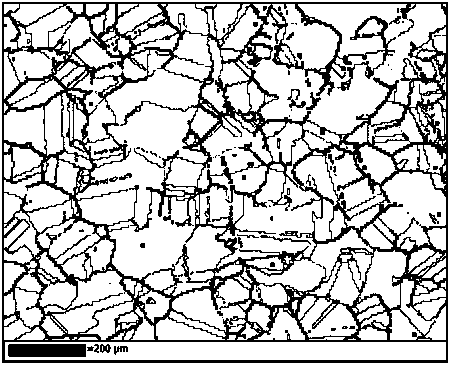

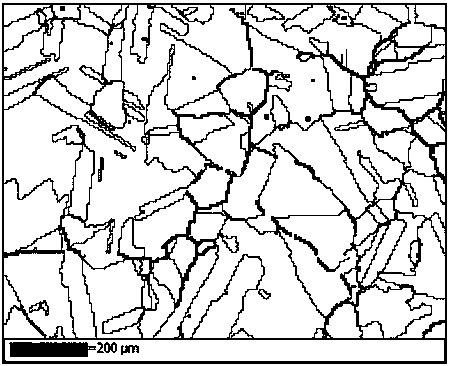

[0018] The material of the component in this example is 316L austenitic stainless steel, and the initial grain boundary structure of the material is as follows: figure 1 As shown, most of its grain boundaries are black large-angle random grain boundaries, and a small part are light-colored low-Σ weight lattice grain boundaries, and the proportion of special grain boundaries is about 70%; according to the deformation heat treatment process described in the patent The grain boundary structure after treatment is as figure 2 As shown, the light-colored low-Σ-heavy lattice grain boundaries were significantly increased and interconnected into low-Σ grain boundary clusters, the proportion of which increased to 85%.

[0019] The specific process steps of this embodiment are:

[0020] Adjust the shape of the 316L stainless steel workpiece, and trim the upper and lower sides to be parallel. Then, solution treatment was performed in a resistance furnace at 1100 °C for 60 minutes. Afte...

Embodiment 2

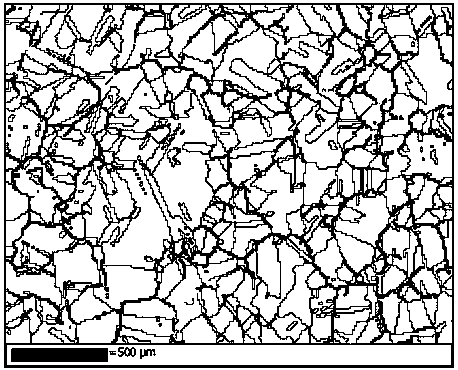

[0022] This example uses the same initial state 316L stainless steel material as Example 1, and its grain boundary structure is the same as Example 1 (such as figure 1 shown). The grain boundary structure treated according to the process described in the patent is as follows: image 3 As shown, the light-colored low-Σ-heavy lattice grain boundaries are significantly increased and interconnected into low-Σ grain boundary clusters, the proportion of which increases to 86%.

[0023] The specific process of this embodiment is:

[0024] After shape trimming, the 316L stainless steel was placed in a resistance furnace at 1100°C for solution treatment for 70 minutes. Take the sample to 1 s -1 The deformation rate was unidirectional compression deformation at room temperature, and the deformation was stopped when the deformation amount reached 5%. The sample was taken out and placed in a resistance furnace at 1100 °C for 100 minutes, and then the material was taken out and water qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com