Method for preparing deodorization type polyacrylic acid series water absorbing resin

A technology of polyacrylic acid series and manufacturing method, which is applied in the direction of coating, etc., and can solve the problems such as deodorizing effect discount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

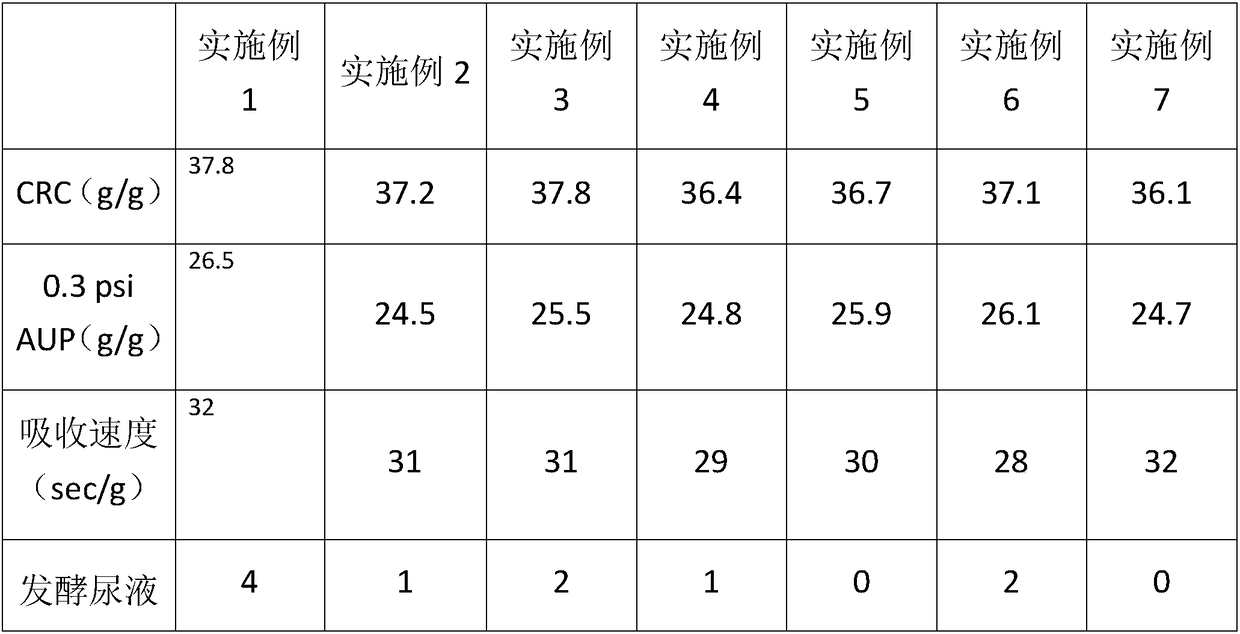

Examples

manufacture example 1

[0137] The acrylic acid / sodium acrylate mixed monomer solution (the molar ratio of acrylic acid / sodium acrylate is 2.2 / 7.8) was transported through pipelines, the monomer concentration of acrylic acid / sodium acrylate was 44.0wt%, and the flow rate of the monomer solution was 8689kg / h. The temperature of the monomer solution is 80-90°C. Polyethylene glycol diacrylate (molecular weight: 522) with a concentration of 11.3 wt% was transported at the branch of the monomer solution pipeline, and the flow rate was 72 kg / h. In addition, the azobisisobutylamidine hydrochloride aqueous solution (flow 50kg / h) and the sodium persulfate aqueous solution (flow 60kg / h) with a concentration of 4wt% were mixed by a delivery pump to form an initiator mixed turbidity. Liquid, and the mixed turbid liquid is transported to the monomer through the branch of the monomer solution pipeline to carry out the polymerization reaction. The reaction solution is sprayed onto the reaction bed to form a monome...

manufacture example 2

[0142] Put 10g of ammonium chloride T and 10g of nonanoyloxybenzenesulfonate (NOBS) in an agate grinding body and grind the ester 100um to obtain powder B

manufacture example 3

[0144] Put 10g of ammonium chloride T and 5g of nonanoyloxybenzenesulfonate (NOBS) in an agate grinding body to grind ester 100um to obtain powder C

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com