Preparation method of low-specific-surface-area high-oil-absorption-value friction type silicon dioxide

A low specific surface area, silicon dioxide technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of excessive specific surface area, toothpaste viscosity after expansion, etc., to reduce specific surface area, reduce viscosity, The effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

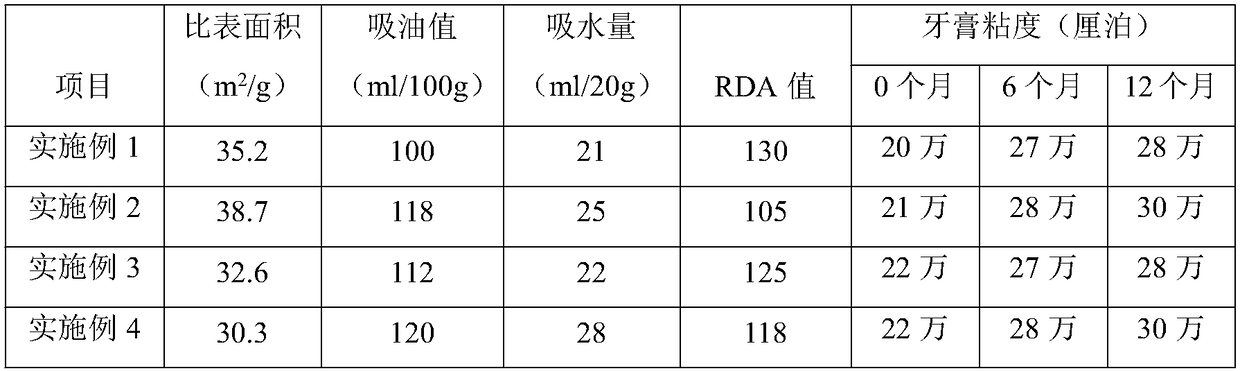

Examples

Embodiment 1

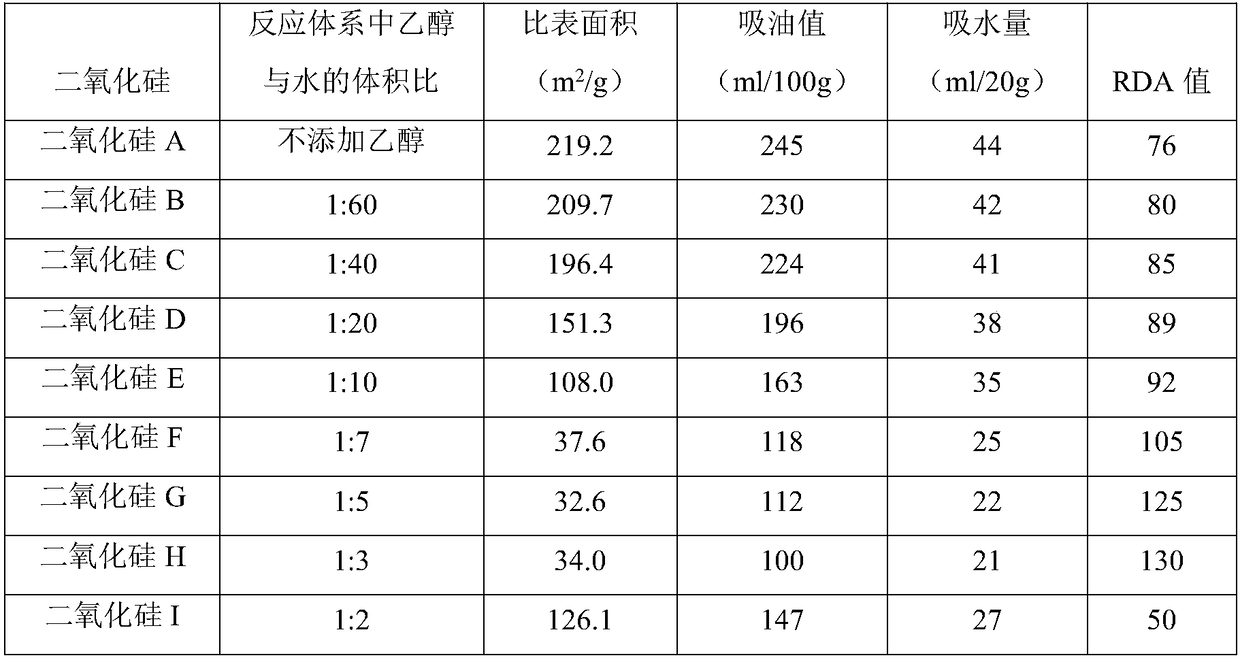

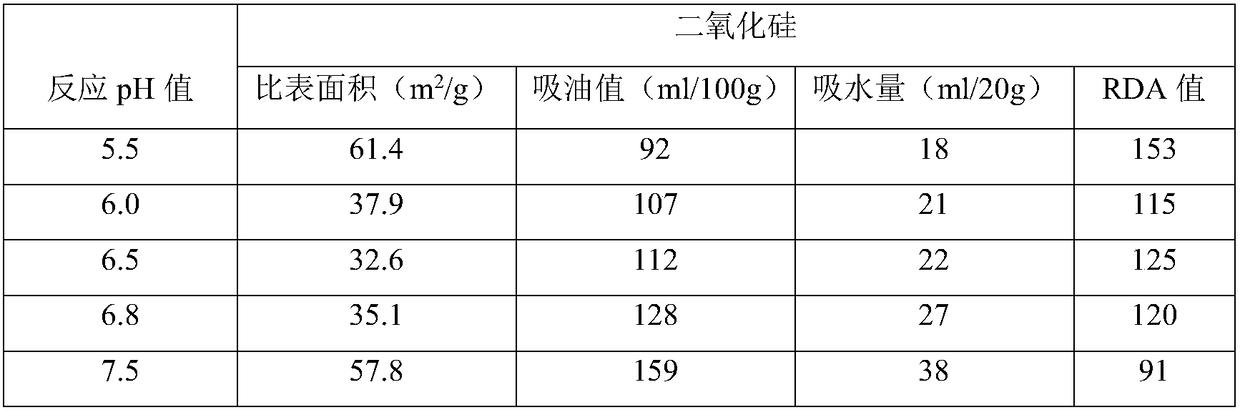

[0024] Example 1. Friction-type silica with low specific surface area and high oil absorption value of the present invention and its preparation

[0025] S1, inject 8m ethanol aqueous solution into the reaction tank 3 , heat up to 60°C, and start stirring;

[0026] S2, drop water glass solution 10m in the reaction tank at the same time 3 Perform parallel flow reaction with sulfuric acid solution, control the titration rate of sulfuric acid solution to control the pH of the reaction process to be 6.0, at the same time, add 1 to 2 m 3 Anhydrous ethanol to keep the volume ratio of ethanol and water in the reaction system at 1:3, and keep the reaction temperature at 60°C. After the water glass solution is added dropwise, stop adding the sulfuric acid solution and continue stirring for 45 minutes;

[0027] S3. Stop stirring and heating, age for 1 hour, press filter and wash the formed silicon dioxide to remove sulfate, dry and pulverize the washed silicon dioxide to obtain fricti...

Embodiment 2

[0033] Example 2. Friction-type silica with low specific surface area and high oil absorption value of the present invention and its preparation

[0034] S1, inject 12m of ethanol aqueous solution into the reaction tank 3 , heat up to 70°C, and start stirring;

[0035] S2, drop water glass solution 10m in the reaction tank at the same time 3 Conduct parallel flow reaction with sulfuric acid solution, control the titration rate of sulfuric acid solution to control the pH of the reaction process to be 6.8, at the same time, add 1 to 2 m 3 Dehydrated ethanol to keep the volume ratio of ethanol and water in the reaction system as 1:7, and keep the reaction temperature at 70°C. After the water glass solution is added dropwise, stop adding the sulfuric acid solution and continue to stir for 60 minutes;

[0036] S3. Stop stirring and heating, age for 1 hour, press filter and wash the formed silicon dioxide to remove sulfate, dry and pulverize the washed silicon dioxide to obtain fr...

Embodiment 3

[0042] Example 3. Friction-type silica with low specific surface area and high oil absorption value of the present invention and its preparation

[0043] S1, inject 10m of ethanol aqueous solution into the reaction tank 3 , heat up to 65°C, and start stirring;

[0044] S2, drop water glass solution 10m in the reaction tank at the same time 3 Perform parallel flow reaction with sulfuric acid solution, control the titration rate of sulfuric acid solution to control the pH of the reaction process to be 6.5, at the same time, add 1 to 2 m 3 Anhydrous ethanol to keep the volume ratio of ethanol and water in the reaction system at 1:5, and keep the reaction temperature at 65°C. After the water glass solution is added dropwise, stop adding the sulfuric acid solution and continue to stir for 50 minutes;

[0045] S3. Stop stirring and heating, age for 1 hour, press filter and wash the formed silicon dioxide to remove sulfate, dry and pulverize the washed silicon dioxide to obtain frict...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com