Cutting device for rubber

A cutting device and rubber technology, applied in metal processing and other directions, can solve the problems of time-consuming, labor-intensive, high-cost, and achieve the effect of convenient and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

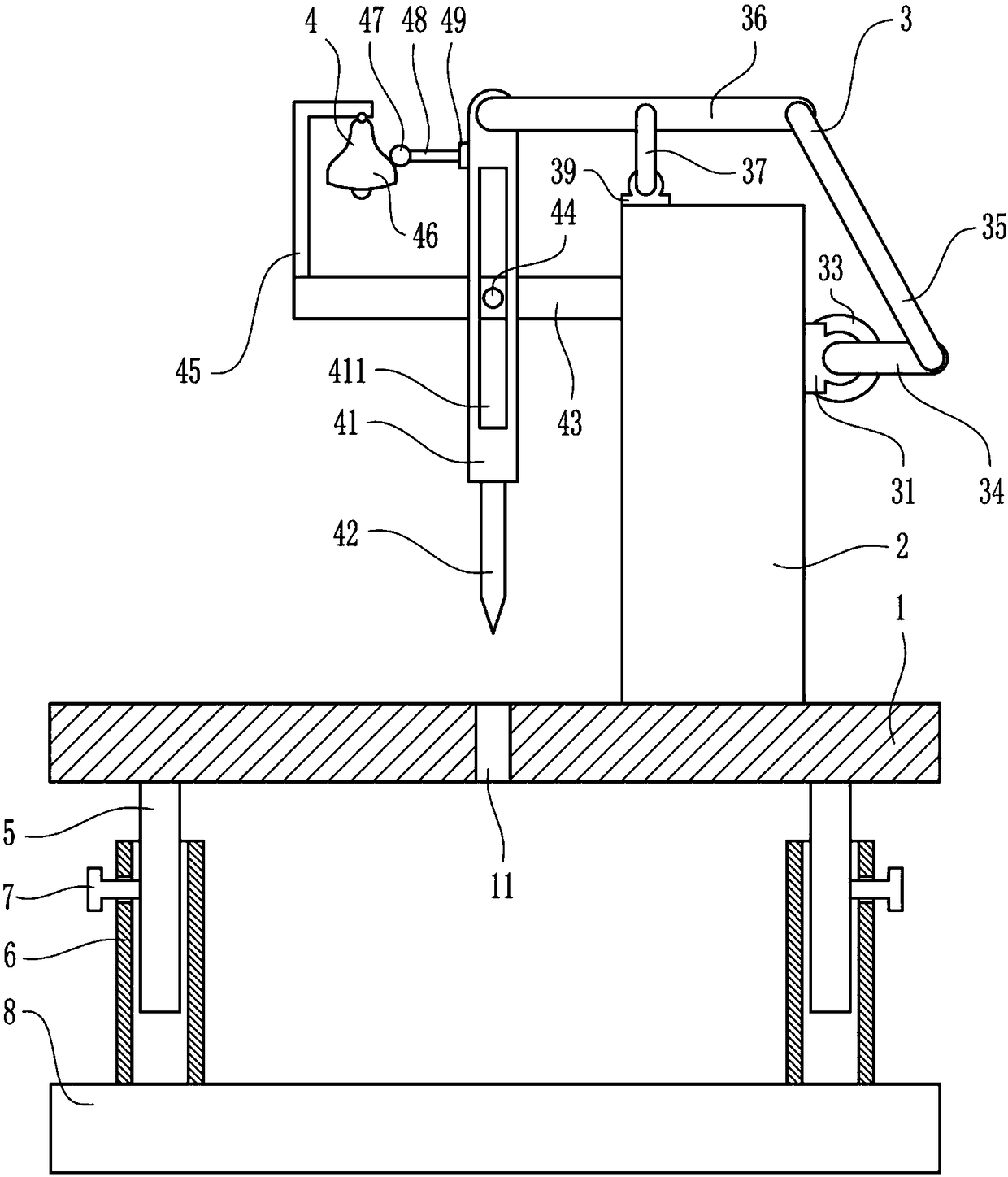

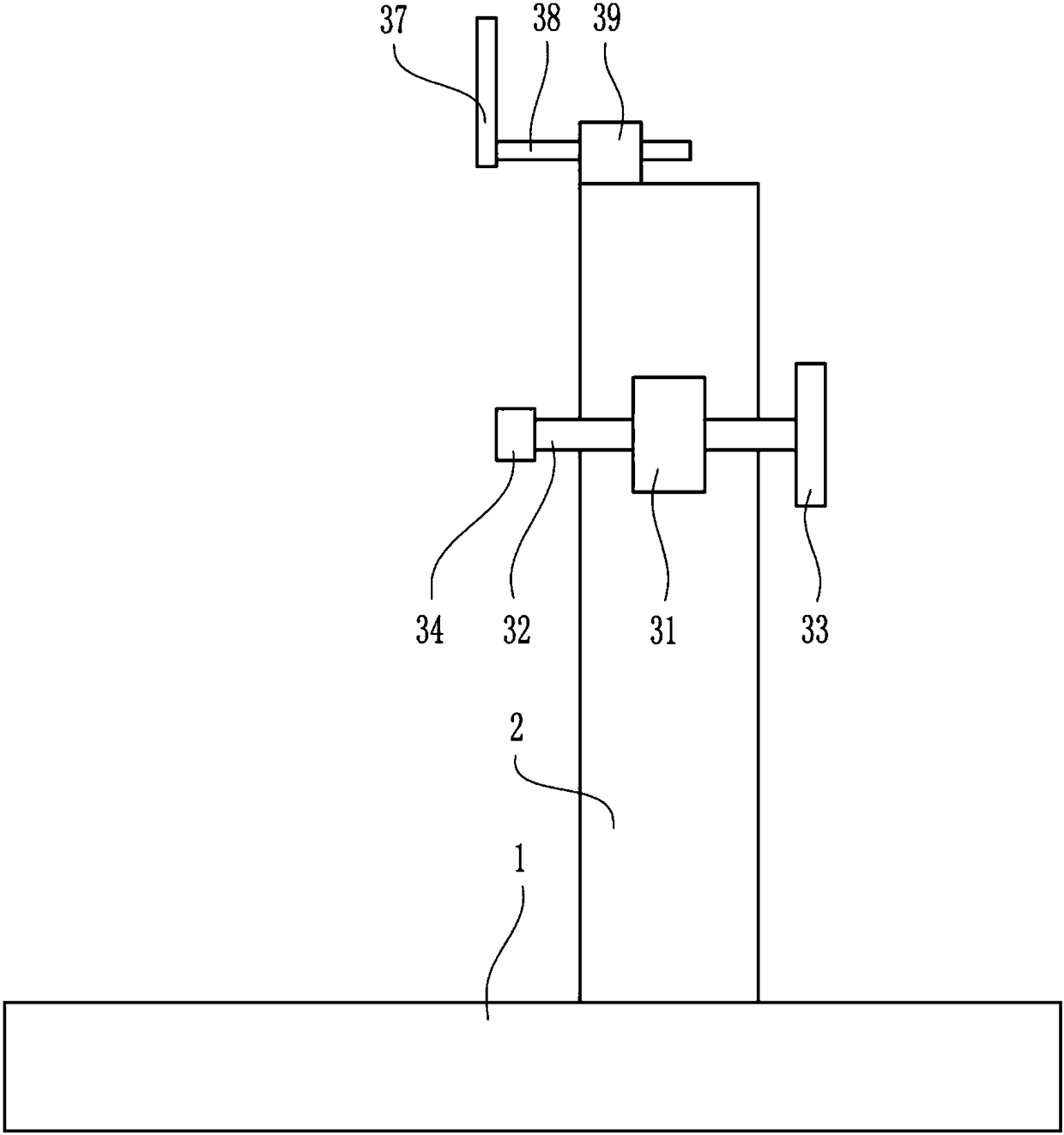

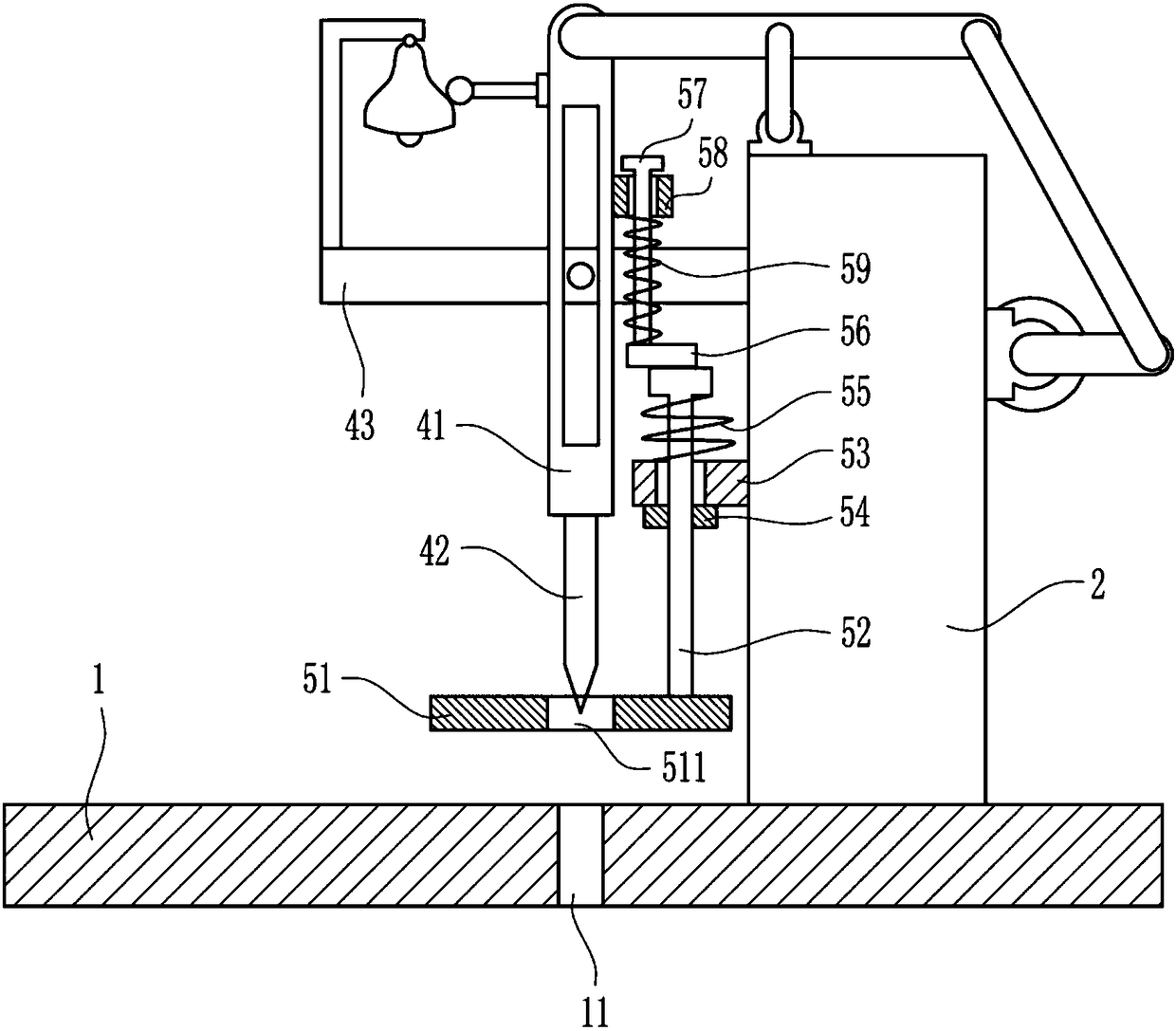

[0032] A cutting device for rubber, such as Figure 1-6 As shown, it includes a workbench 1, a large fixed plate 2, a driving device 3, a cutting device 4, an elevating rod 5, a sleeve 6, a positioning screw 7 and a base 8; the large fixed plate 2 is located above the workbench 1, and the large fixed plate The plate 2 and the worktable 1 are fixedly connected, the large fixed plate 2 is provided with a driving device 3, the cutting device 4 is located on the left side of the large fixed plate 2, the lifting rod 5 is located under the workbench 1, and the lifting rod 5 is connected to the workbench. 1 is set as a fixed connection, the lifting rod 5 is slidingly located in the casing 6, and the side wall of the casing 6 is provided with a positioning screw 7, and the positioning screw 7 and the casing 6 are set as threaded connections, and the positioning screw 7 and the lifting rod 5 In contact with each other, the lifting rod 5, the casing 6 and the positioning screw 7 are arr...

Embodiment 2

[0034] A cutting device for rubber, such as Figure 1-6 As shown, it includes a workbench 1, a large fixed plate 2, a driving device 3, a cutting device 4, an elevating rod 5, a sleeve 6, a positioning screw 7 and a base 8; the large fixed plate 2 is located above the workbench 1, and the large fixed plate The plate 2 and the worktable 1 are fixedly connected, the large fixed plate 2 is provided with a driving device 3, the cutting device 4 is located on the left side of the large fixed plate 2, the lifting rod 5 is located under the workbench 1, and the lifting rod 5 is connected to the workbench. 1 is set as a fixed connection, the lifting rod 5 is slidingly located in the casing 6, and the side wall of the casing 6 is provided with a positioning screw 7, and the positioning screw 7 and the casing 6 are set as threaded connections, and the positioning screw 7 and the lifting rod 5 In contact with each other, the lifting rod 5, the casing 6 and the positioning screw 7 are arr...

Embodiment 3

[0037] A cutting device for rubber, such as Figure 1-6 As shown, it includes a workbench 1, a large fixed plate 2, a driving device 3, a cutting device 4, an elevating rod 5, a sleeve 6, a positioning screw 7 and a base 8; the large fixed plate 2 is located above the workbench 1, and the large fixed plate The plate 2 and the worktable 1 are fixedly connected, the large fixed plate 2 is provided with a driving device 3, the cutting device 4 is located on the left side of the large fixed plate 2, the lifting rod 5 is located under the workbench 1, and the lifting rod 5 is connected to the workbench. 1 is set as a fixed connection, the lifting rod 5 is slidingly located in the casing 6, and the side wall of the casing 6 is provided with a positioning screw 7, and the positioning screw 7 and the casing 6 are set as threaded connections, and the positioning screw 7 and the lifting rod 5 In contact with each other, the lifting rod 5, the casing 6 and the positioning screw 7 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com