Cell module mounting and fixing structure

A fixed structure and cell module technology, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of low charging efficiency, restricting the promotion and use of pure electric vehicles, and can not be solved, so as to achieve high support strength , compact structure, novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

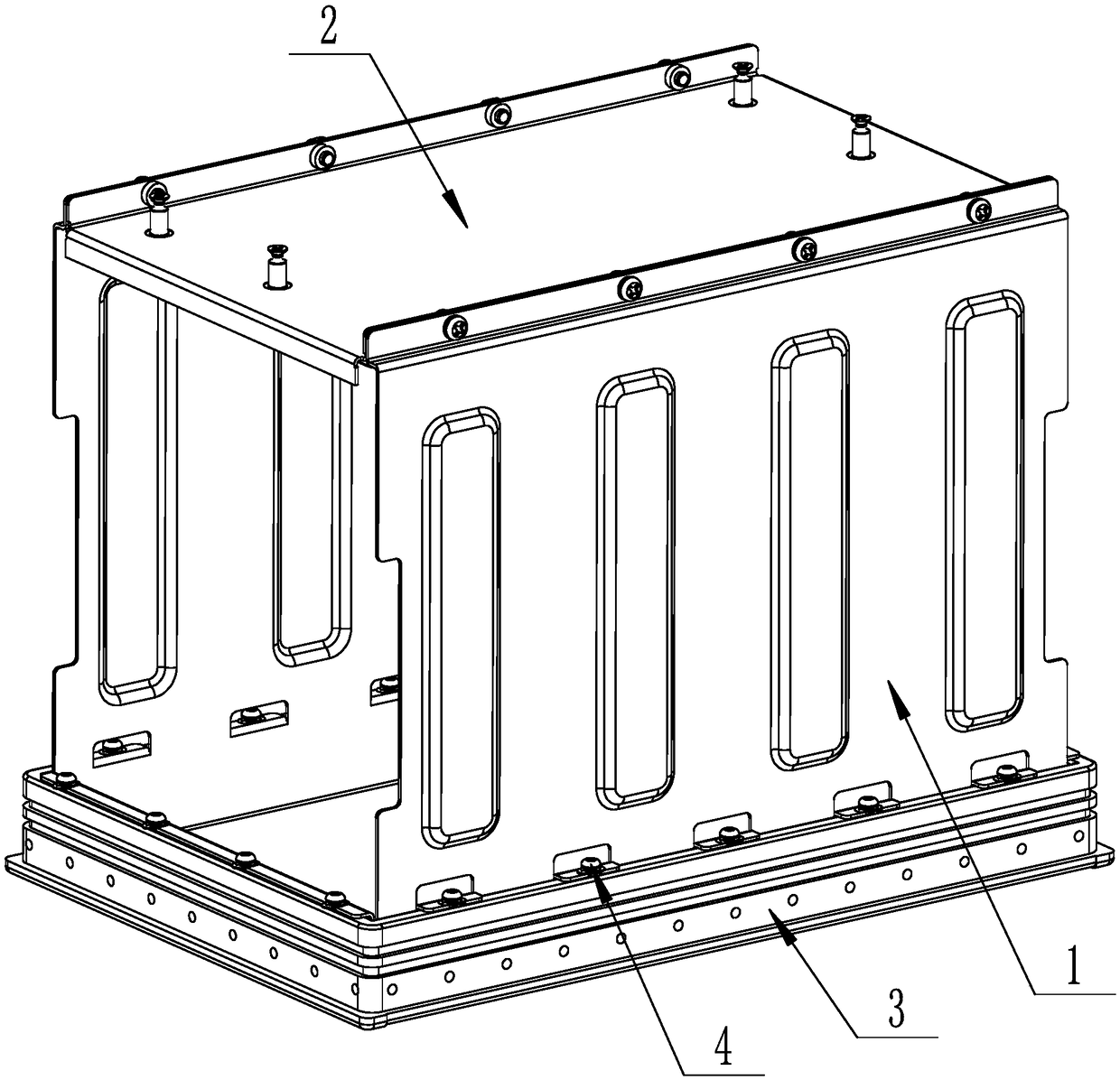

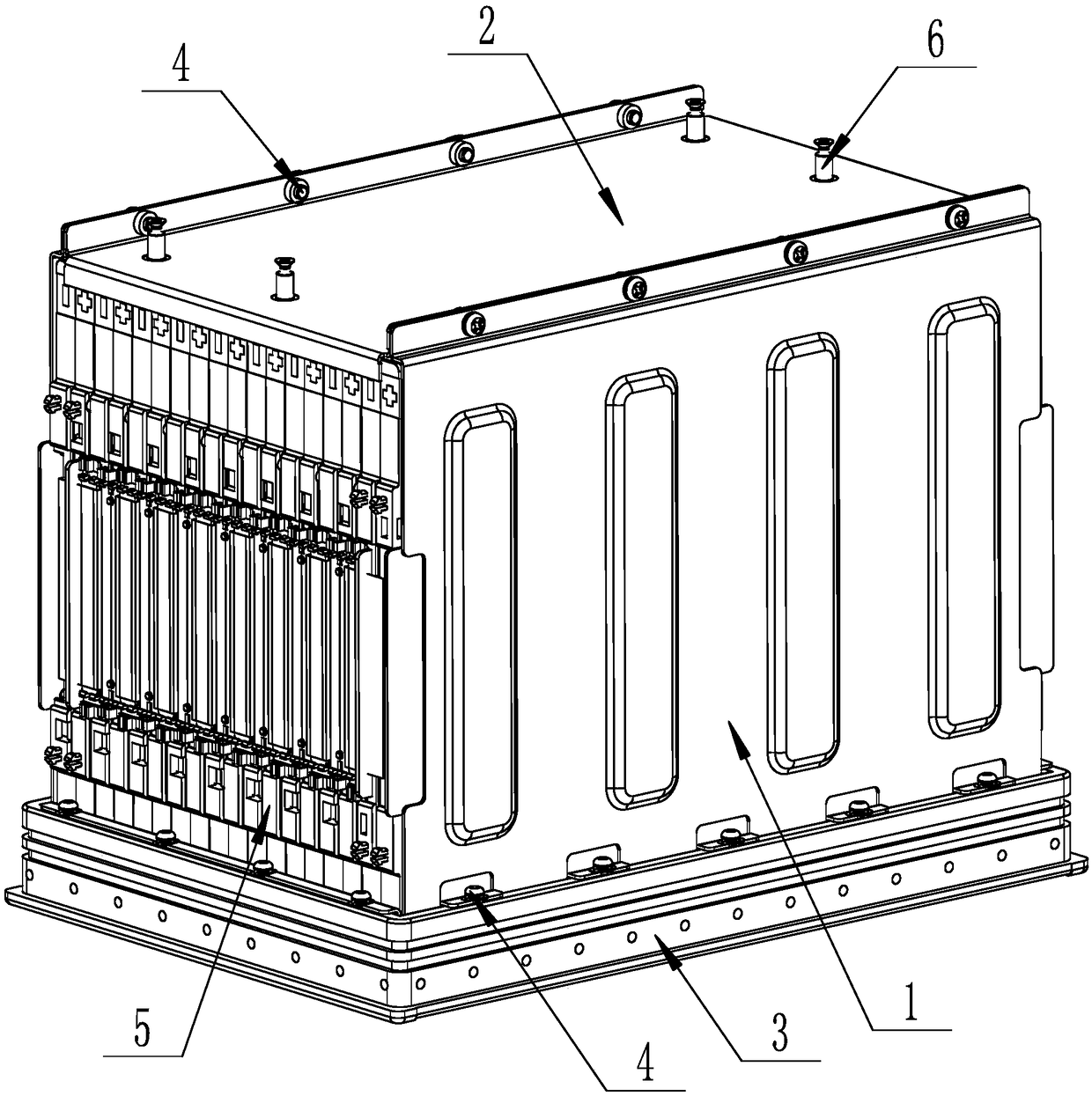

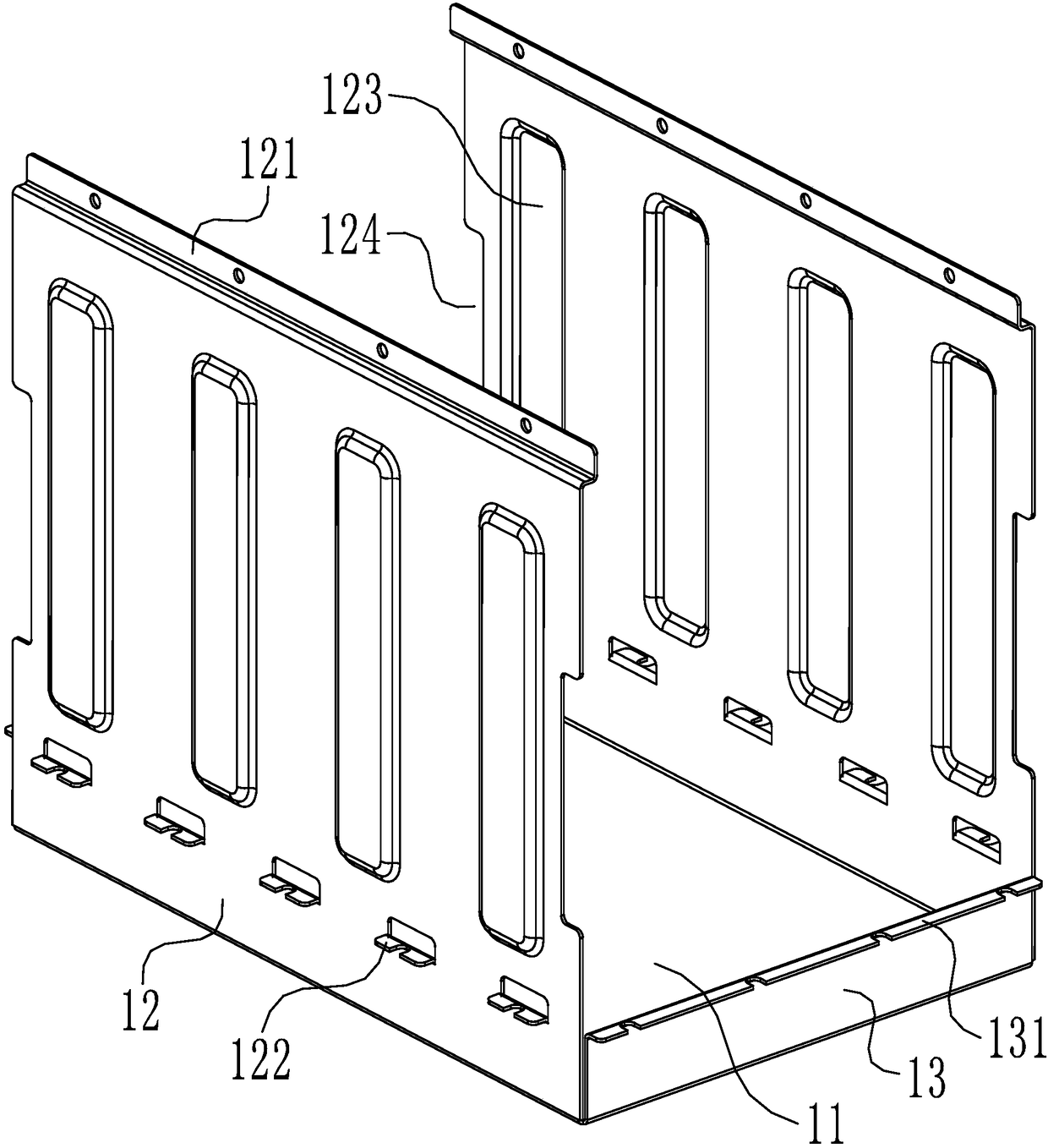

[0025] See figure 1 with figure 2 , a cell module installation and fixing structure, including a module fixing base 1, a module fixing top plate 2 and a base 3, a frame structure is formed by enclosing the module fixing base 1 and the module fixing top plate 2, and combined with the base 3, The cell module 5 can be stably and reliably installed and fixed, and has a compact structure and high support strength.

[0026] See figure 1 , figure 2 with Figure 5 , the base 3 is made of aluminum alloy, which not only has high strength, but also has low wear rate, good wear resistance, and light weight, which meets the requirements of vehicle lightweight design. The base 3 is a rectangular box-shaped structure with an upper opening. The outer edge of the bottom wall 32 of the base 3 has an outwardly protruding annular boss 33, and two annular bosses 33 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com