Optical fiber micro-displacement sensing and calibrating device and method

A correction device and micro-displacement technology, applied in the field of displacement sensing, can solve the problems of difficult detection and correction of small optical fiber deviations, and achieve excellent sensing and correction effects, wide application range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

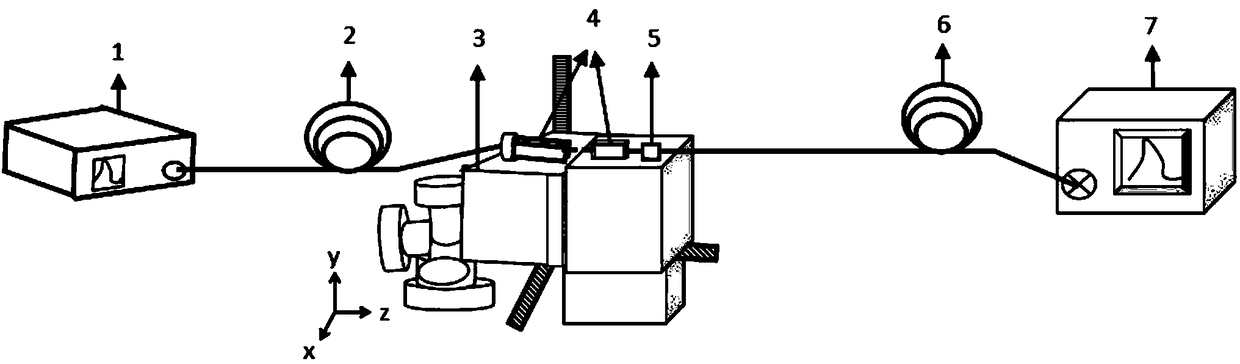

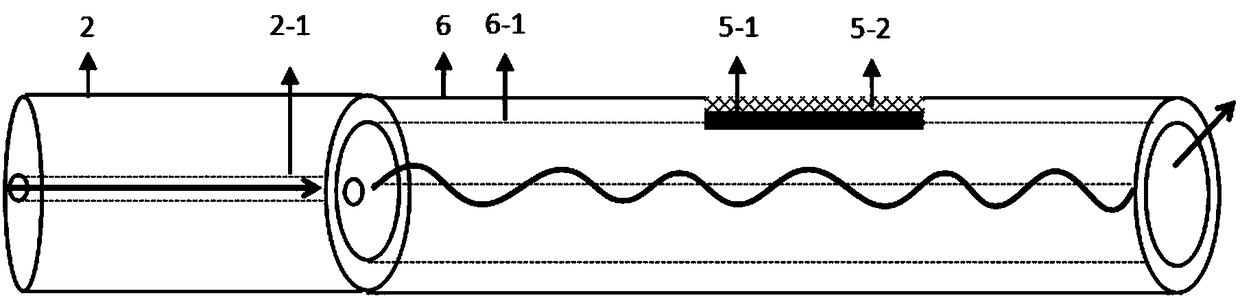

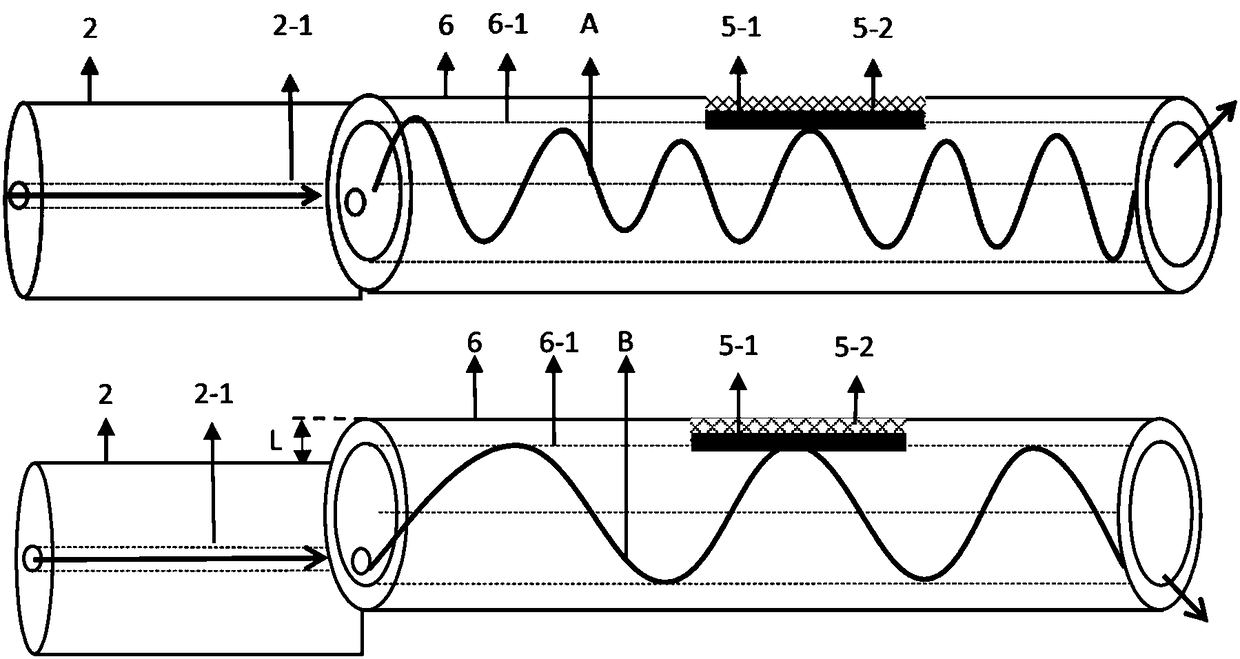

[0046] Combine below figure 1 , 2 , 3, 4 illustrate this embodiment, the present invention is an optical fiber micro-displacement sensing and correction device and method, which can detect the change of the position of the optical fiber with high sensitivity, long distance, and real-time, so as to perform correction and enhance the controllability of the optical fiber , the operation is simple and easy to implement, and it solves the problem that the small deviation of the optical fiber caused by the small size of the optical fiber is difficult to find and correct when the position of the outgoing light of the optical fiber is specified.

[0047] The optical fiber micro-displacement sensing and correction device is composed of a light source 1, a three-dimensional micro-displacement platform 3, an optical fiber fixture 4, a micro-displacement SPR sensing probe 5, a gradient multimode optical fiber 6 and a spectrometer 7;

[0048] The light source 1 is a supercontinuum light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com