Self-adaptive support structure of collapse preventing and treating engineering and method thereof

A support structure and prevention engineering technology, applied in the direction of building types, buildings, protected buildings/shelters, etc., can solve problems such as sloppy construction of support columns, insufficient depth of support column foundation, poor stability of upper rock mass, etc. To achieve the effect of shortening the project rescue time, shortening the construction time and reducing the disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

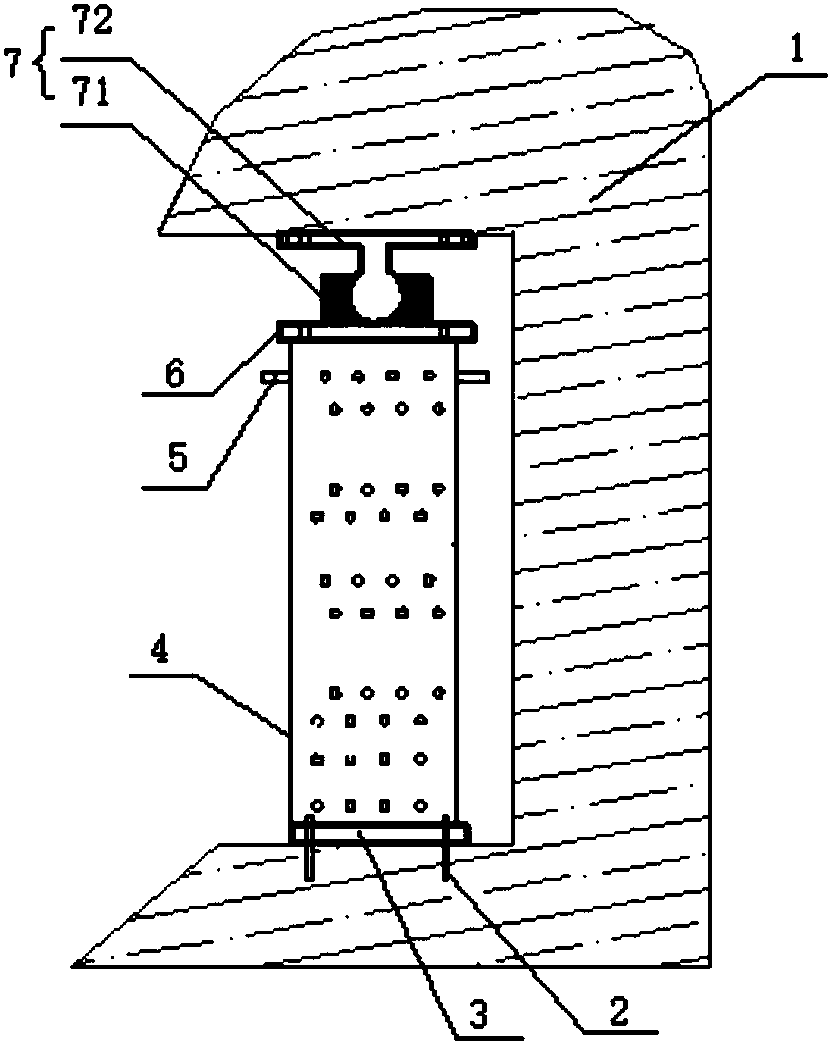

[0038] Such as figure 1 As shown, an adaptive support structure for collapse prevention engineering includes a first steel backing plate 3, a support column 4, a second steel backing plate 6 and an adaptive top brace 7, wherein the first steel backing plate 3 is placed on a dangerous rock mass 1, the bottom of the concave cavity, the first steel backing plate 3 is fixed on the bottom of the dangerous rock mass 1 concave cavity through the technology of steel bar 2 planting, the supporting column 4 is located on the first steel backing plate 3, the bottom of the supporting column 4 and the first steel pad The plate 3 is fixed by welding, the second steel backing plate 6 is fixed on the top of the supporting column 4, the second steel backing plate 6 and the supporting column 4 are fixed by welding, and the adaptive top brace 7 is fixed on the second steel backing plate by bolts 6, the top of the self-adaptive top brace 7 contacts the top of the concave cavity of the dangerous r...

Embodiment 2

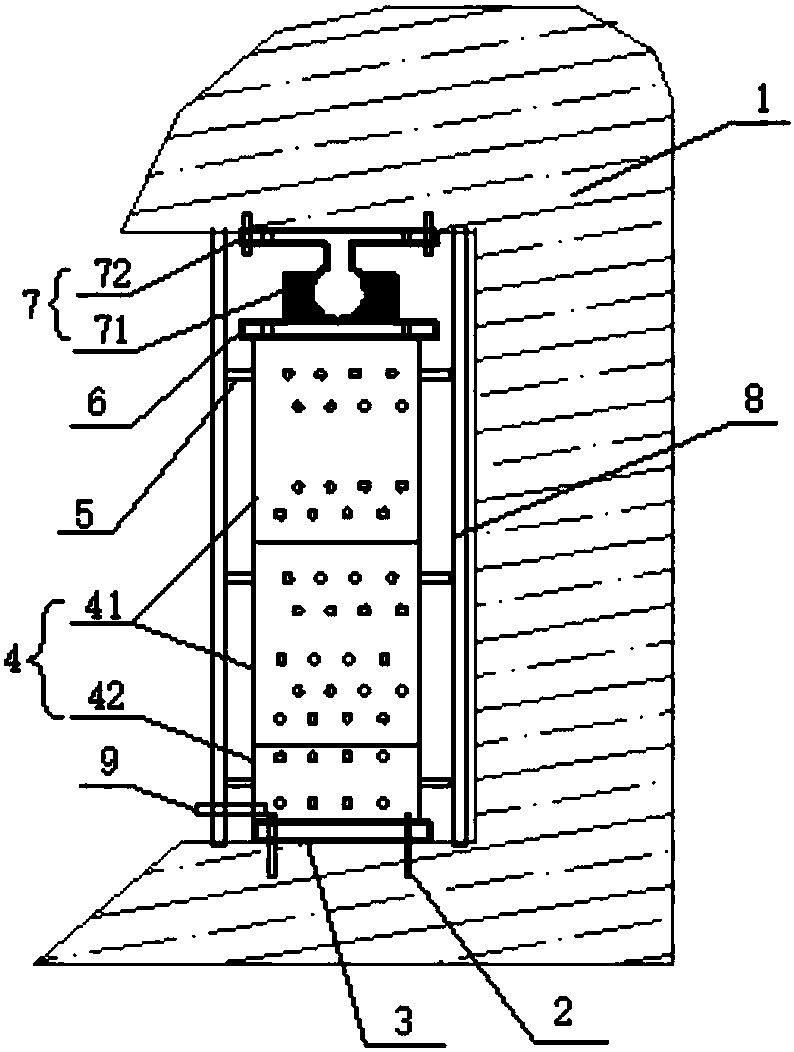

[0042] Such as figure 2 As shown, an adaptive support structure for collapse prevention engineering includes a first steel backing plate 3, a support column 4, a second steel backing plate 6 and an adaptive top brace 7, wherein the first steel backing plate 3 is placed on a dangerous rock mass 1 The bottom of the concave cavity, the first steel backing plate 3 is fixed on the bottom of the dangerous rock mass 1 cavity through the technology of steel bar 2 planting bars, the supporting column 4 is located on the first steel backing plate 3, and the supporting column 4 is a multi-section spiral steel pipe 41 Assembled and formed, the spiral steel pipes 41 are fixed by self-locking screw connections, the bottom of the support column 4 and the first steel backing plate 3 are fixed by welding, and the top of the support column 4 is fixed with a second steel backing plate 6, the second steel backing The plate 6 and the support column 4 are fixed by welding, and the self-adaptive to...

Embodiment 3

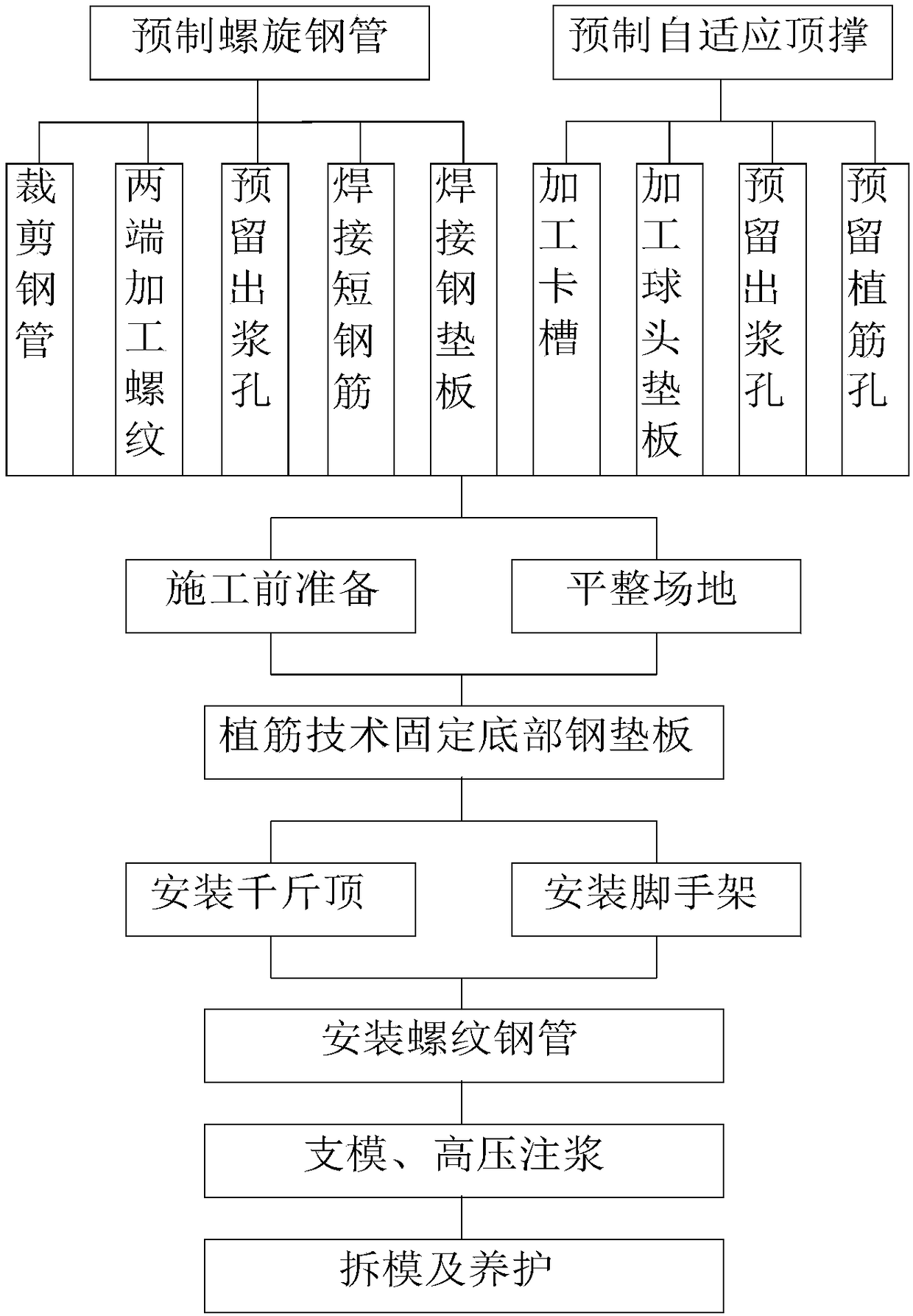

[0045] Such as image 3 Shown, utilize self-adaptive supporting structure of the present invention to prevent and treat the method for dangerous rock mass 1 collapse, specifically comprise the following steps:

[0046] 1) Prefabricated spiral steel pipe 41

[0047] For the convenience of transportation and secondary handling, the length of the spiral steel pipe 41 is 1.5m. At the steel pipe height 1.2m, weld four 15cm long short steel bars 5 for the jack to act on the spiral steel pipe 41 lifting operation, and pour the thickness of the protective layer after mold making. A slurry hole is reserved on the wall of the spiral steel pipe 41 .

[0048] A second steel backing plate 6 is welded on the top of one of the spiral steel pipes 41, and the second steel backing plate 6 has a concrete mortar overflow hole. All the other spiral steel pipes 41 do not have a steel backing plate.

[0049] 2) Prefabricated adaptive top support 7

[0050] Self-adaptive top support 7 base 71 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com