Technology for preparing low-cost adsorbent by using coaly fly ash

An adsorbent, low-cost technology, applied in the direction of adsorption water/sewage treatment, inorganic chemistry, water/sludge/sewage treatment, etc., can solve problems such as heavy metal pollution, soil, water source and crop hazards, fly ash cannot be used, etc. Achieve high efficiency, low cost, and reduce the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A process for preparing a low-cost adsorbent from coal-based fly ash, comprising the following steps:

[0027] In step 1, coal-based fly ash is added into a reactor, and zeolization treatment is carried out under microwave irradiation conditions to obtain treated fly ash.

[0028] Step 2: Weigh the treated fly ash and sodium hydroxide according to the mass ratio of 1:5, and add 1L of water for mixing to obtain a suspension with a mass concentration of 10g / L.

[0029] Step 3, adding the suspension into the reaction tank for stirring to obtain a slurry. In this embodiment, the stirring temperature is 30°C-90°C, and the stirring time is 6h-18h.

[0030] In step 4, after the slurry is left to stand at room temperature for 1 h to 10 h, the supernatant is discarded, and the lower layer is irradiated with microwaves to obtain an adsorbent. In this embodiment, the microwave irradiation time is 10 minutes to 60 minutes.

[0031] Step 5, performing dilution or concentration pr...

Embodiment 2

[0037] In the present embodiment 2, regarding the same steps and conditions as in the embodiment 1, the same explanations are omitted.

[0038] In step 2 of this embodiment, take the fly ash and sodium hydroxide after treatment according to the mass ratio of 1:5, and add 1 / 3L water to mix to obtain a suspension with a mass concentration of 30g / L. The remaining implementation steps and conditions are the same as Example 1 is the same.

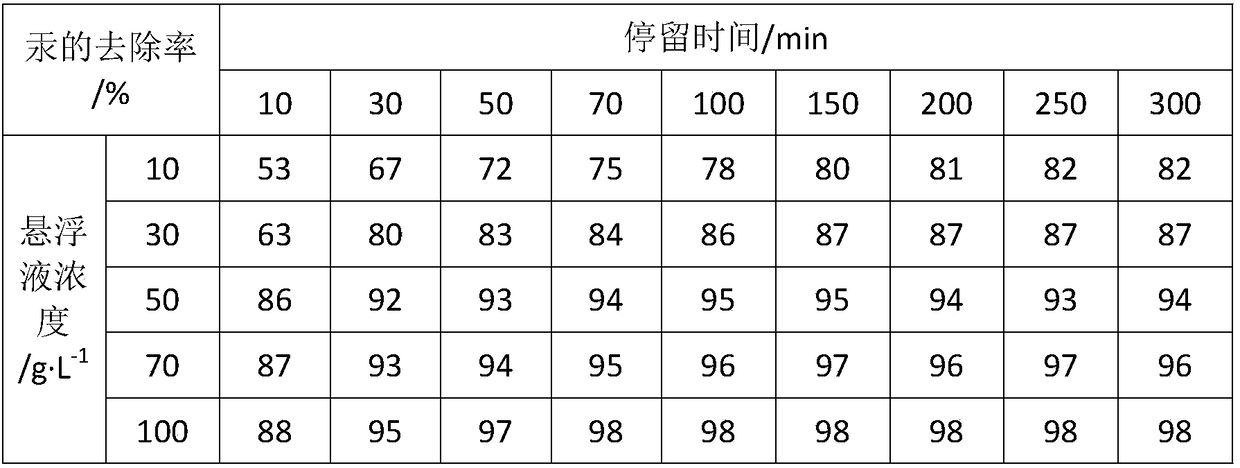

[0039] The experimental results show that the removal rate of heavy metals obtained after the industrial wastewater is mixed and adsorbed by the adsorbent prepared by the suspension with a mass concentration of 30g / L is shown in Table 1.

Embodiment 3

[0041] In the present embodiment 3, regarding the same steps and conditions as in the embodiment 1, the same explanations are omitted.

[0042] In step 2 in this embodiment, take the processed fly ash and sodium hydroxide according to the mass ratio of 1:5, and add 1 / 5L water to mix to obtain a suspension with a mass concentration of 50g / L. The rest of the implementation steps and conditions are the same as Example 1 is the same.

[0043] The experimental results show that the removal rate of heavy metals obtained after the industrial wastewater is mixed and adsorbed by the adsorbent prepared by the suspension with a mass concentration of 50g / L is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com