Homogenization emulsification machine

A homogeneous emulsification and emulsification tank technology, applied in mixers, mixer accessories, chemical instruments and methods, etc., can solve problems such as poor emulsification effect, and achieve the effects of improving production quality, improving quality, and improving emulsification quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

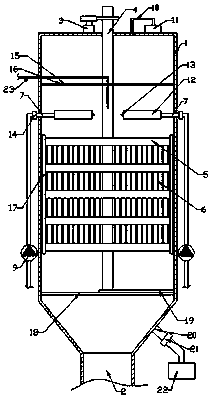

[0024] As the best embodiment of the present invention, this embodiment discloses a homogeneous emulsifier, the specific structure is as follows figure 1 As shown, it includes an emulsification tank 1, the bottom of the emulsification tank 1 is provided with a discharge port 2, the discharge port is provided with a sampling port 20, and the sampling port 20 is provided with a gravity check valve 21 and a collecting bottle 22; The top of the emulsification tank 1 is provided with a motor 3, and a rotating shaft 4 is installed in the emulsification tank 1, and the rotating shaft 4 is connected with the motor 3; There are multiple stirring steel wires 6 in the two joints; the edge of the stirring steel wire 6 is provided with a scraper 17 in contact with the inner wall of the emulsification tank 1; The inlet 7 and the oil phase inlet 8, the water phase inlet 7 and the oil phase inlet 8 are located on one side of the emulsification tank 1 and connected with a semicircular branch p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com