A mechanical vibration-electric energy conversion device with integrated mechanical rectification mechanism

A technology of mechanical rectification and mechanical vibration, applied in electromechanical devices, transmission devices, control of mechanical energy, etc., can solve problems such as low reliability, aggravated wear, and screw bending, so as to improve energy utilization and reliability, and improve power generation. Efficiency and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

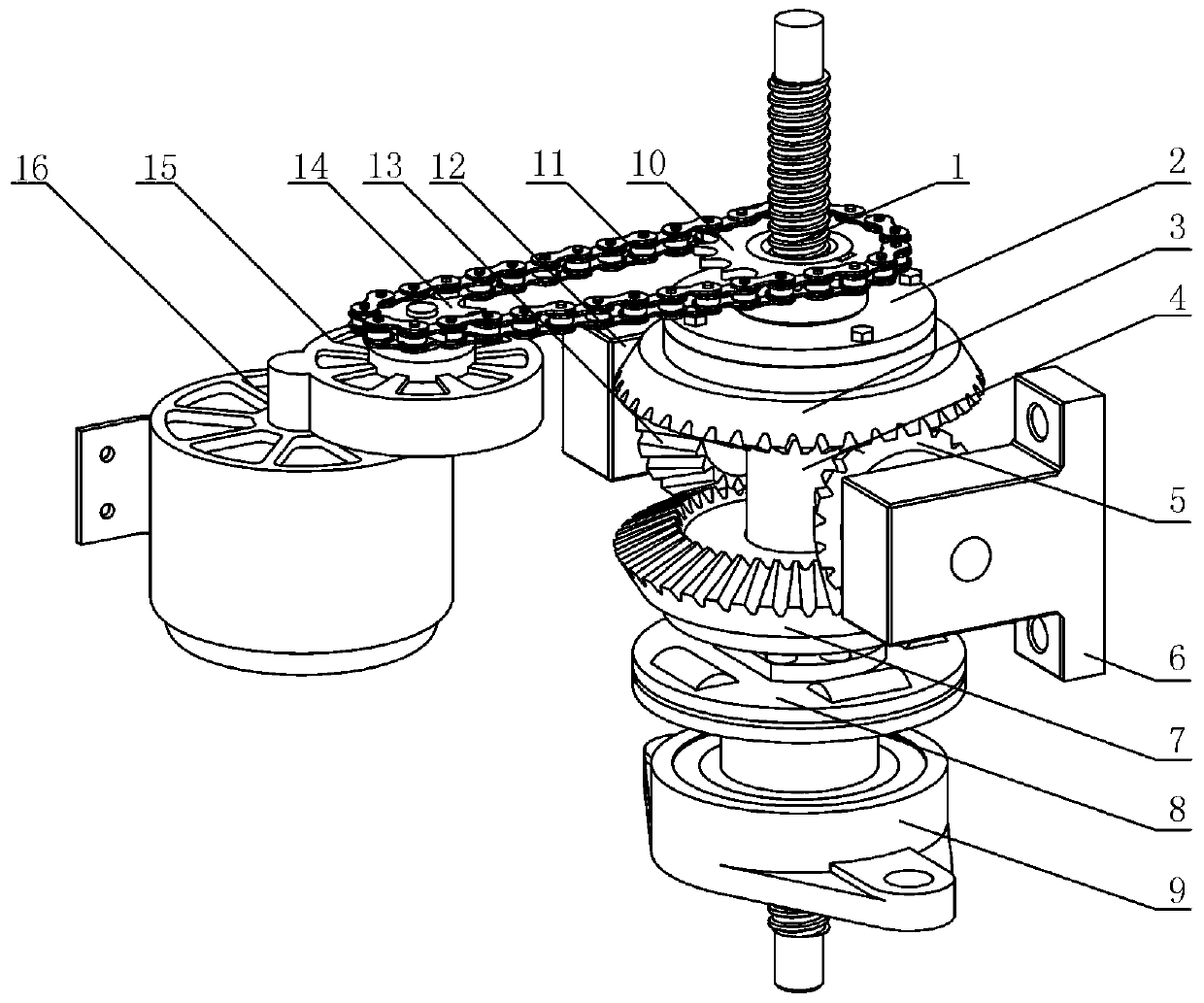

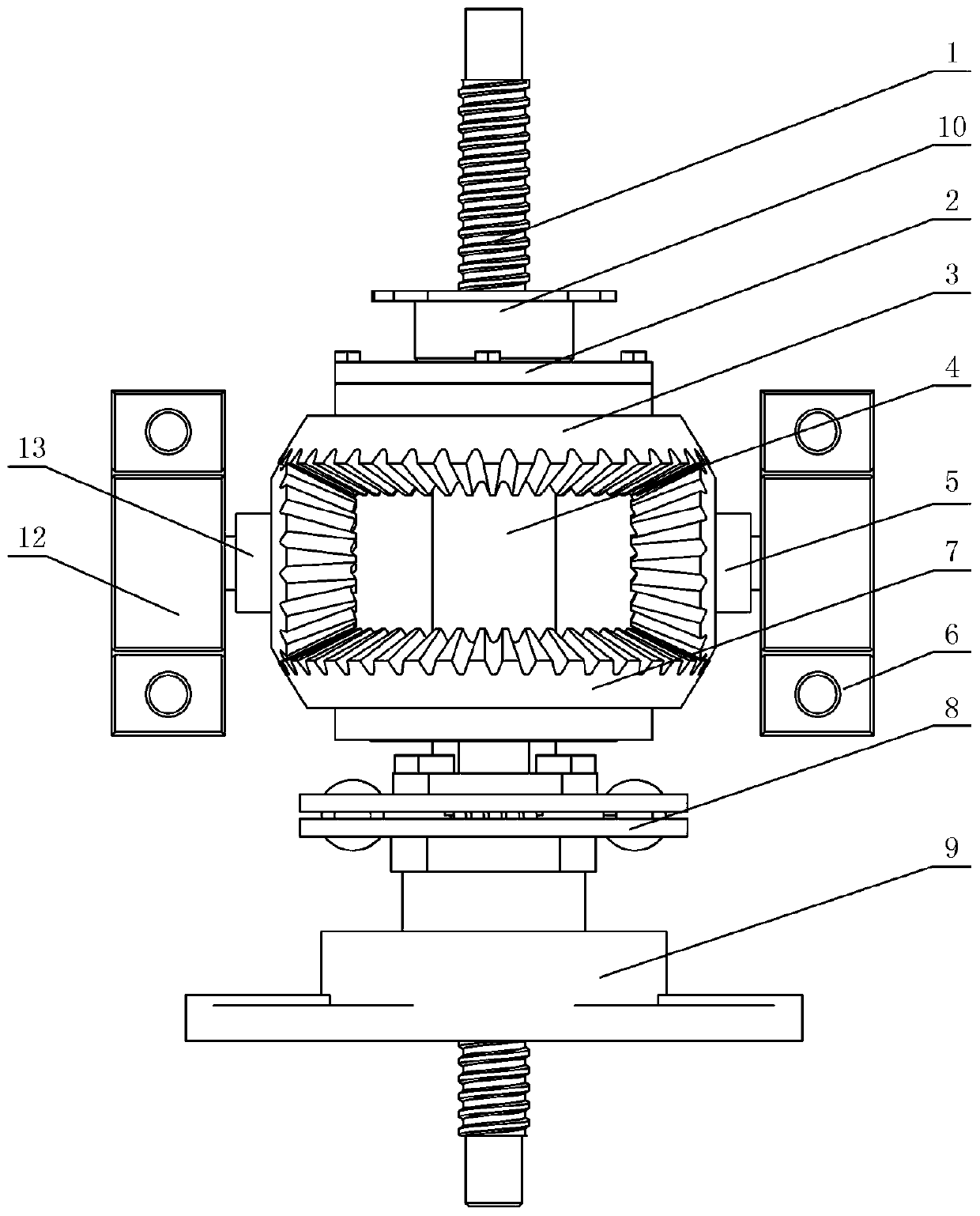

[0035] The specific implementation of the mechanical vibration-electric energy conversion device integrated with the mechanical rectification mechanism of the present invention will be described in detail below with reference to the accompanying drawings.

[0036] Please refer to figure 1 and figure 2 , the mechanical vibration-electric energy conversion device of the integrated mechanical rectification mechanism of this embodiment, its structure is specifically:

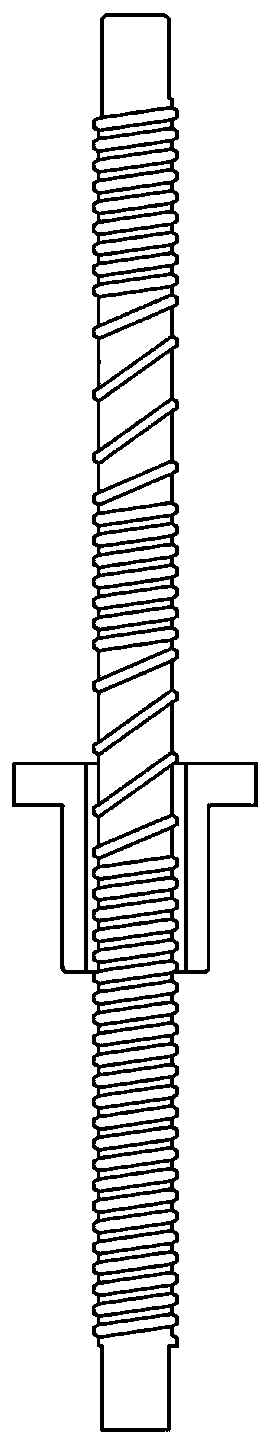

[0037] A motion conversion mechanism is provided to convert the linear motion of mechanical vibration into rotational motion, which is: the top end of the nut of the ball screw pair supported by the first bearing passes through the torsional shock absorber 8 and the connecting sleeve 4 of the mechanical rectification mechanism The bottom end is coaxial and fixedly connected, and the up and down movement of the screw 1 caused by vibration is converted into the bidirectional rotational movement of the nut through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com