Automatic cleaning apparatus of crystallization electrolyte of lithium battery electrolyte injection station

A lithium battery injection and automatic cleaning technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as product quality impact, difficulty in long-term implementation, and impact on the sealing of the injection cavity, so as to keep clean and tidy , to ensure normal operation and avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

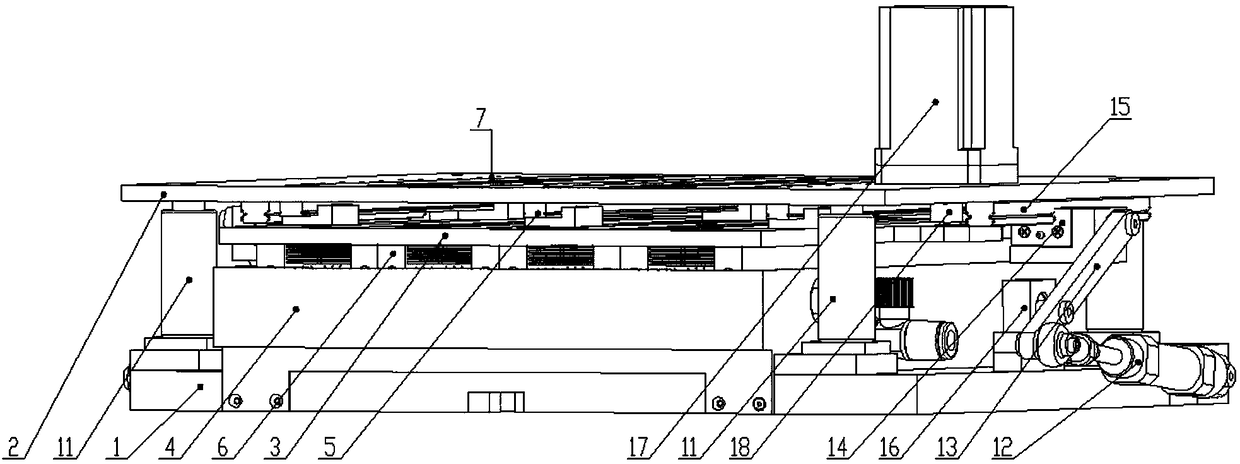

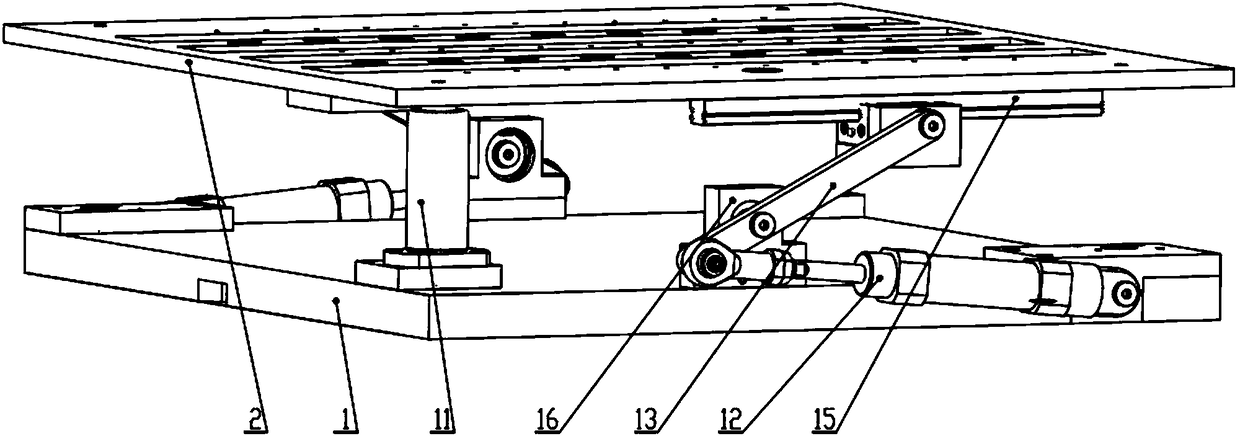

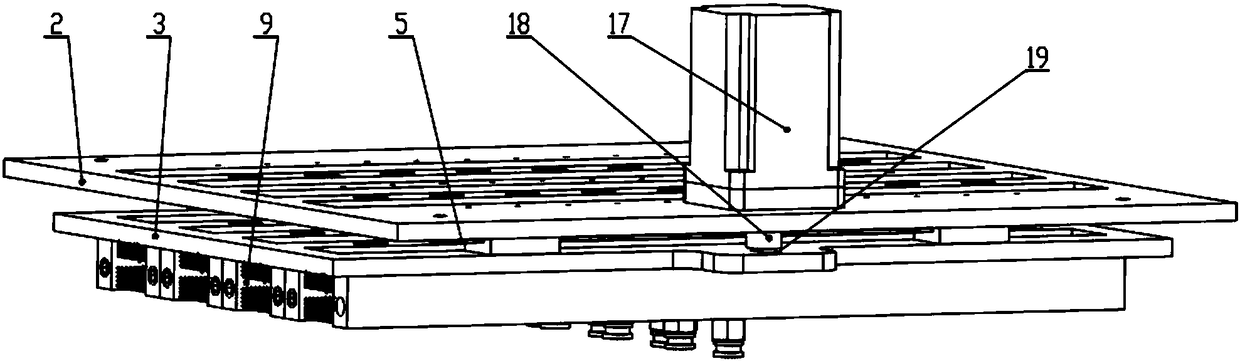

[0020] like figure 1 As shown, an automatic cleaning device for crystallized electrolyte of a lithium battery injection station includes a bottom plate 1, a fixed plate 2, a moving plate 3 and a water tank 4. The device is set on the bottom plate 1, the bottom of the fixed plate 2 is provided with a transverse guide rail 5, the moving plate 3 is slidably installed on the said transverse guide rail 5, and the fixed plate 2 is also provided with a device to drive the said moving plate 3 to slide back and forth along the transverse guide rail 5. The driving device, the moving plate 3 is fixed with a plurality of brushes 6 for cleaning the outer peripheral surface of the liquid injection chamber 21 of the lithium battery liquid injection station 20, and the fixed plate 2 is provided with a plurality of brushes 6 for the injection The liquid cavity 21 passes through to contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com