Light beam MEMS quick regulation and control system

A control system and fast technology, applied in the field of lasers, can solve problems affecting processing accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

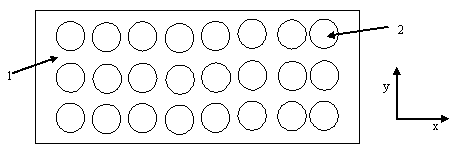

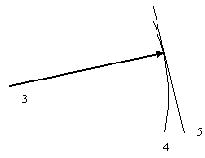

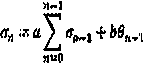

[0015]In this embodiment, the MEMS quick adjustment mirror system 1 is composed of a plurality of single MEMS microlenses 2, the single MEMS microlens 2 can be rolled along the X and Y axes, and the microlens can be rolled along the X axis to adjust the input laser spot in the X direction. The movement of the microlens along the Y-axis direction and the rolling of the microlens along the Y-axis direction can adjust the movement of the input laser spot in the Y-axis direction. Therefore, the MEMS fast adjustment mirror system 1 can arbitrarily adjust the position of the laser spot in the two-dimensional plane formed by the XY axis. The MEMS fast adjustment mirror system 1 is located in the second space where the control system constitutes the core space of the control system, and the MEMS fast adjustment mirror system 1 has a coherent micro lens 2 formed by a single MEMS microlens 2 that can realize various ergodic processes. The lens matrix, the single MEMS microlens 2 has wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com