Acoustic emission signal-based PBX damage evolution CT in-situ analysis method

An acoustic emission signal and damage evolution technology, which is applied in the direction of material analysis, material analysis, and measurement devices using wave/particle radiation, can solve the problems of increased experimental costs and the inability to capture microcrack initiation and propagation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

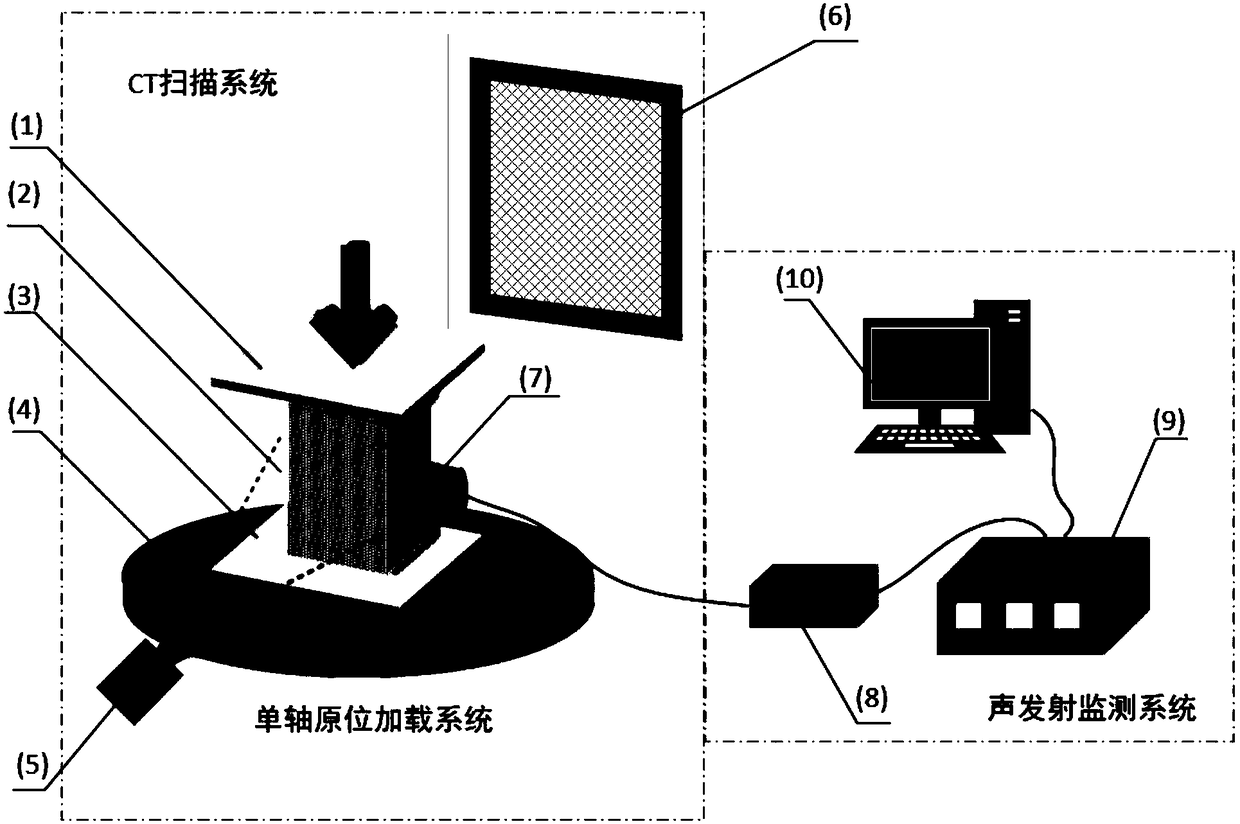

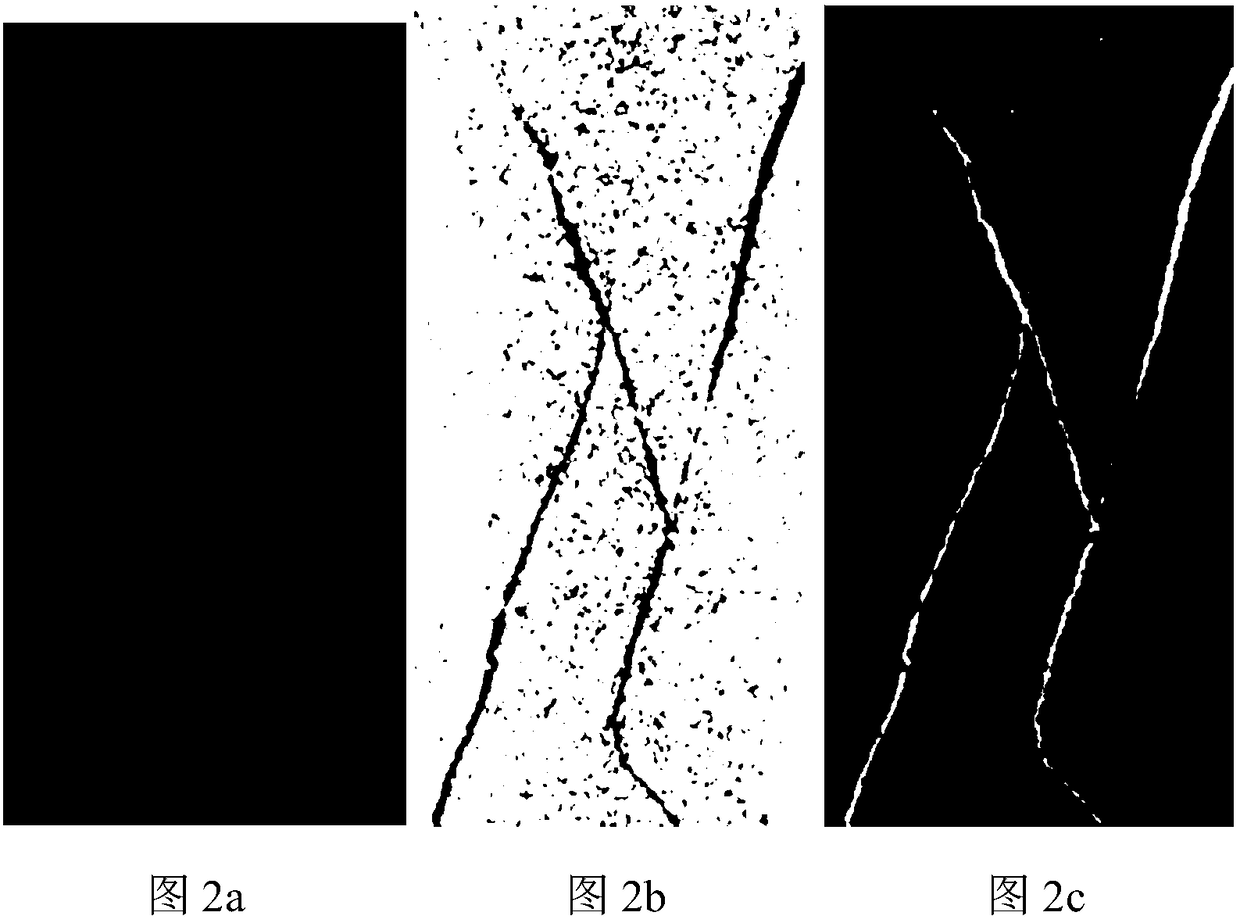

[0044] Such as figure 1 As shown, the detection steps of the method of the present invention are as follows: firstly build a CT in-situ loading and damage detection experimental system, which is composed of a single-axis in-situ loading system, a CT scanning system and an acoustic emission monitoring system; simultaneously implement mechanical loading and acoustic emission Signal acquisition, determine CT scanning load nodes according to the characteristics of acoustic emission signals, and collect CT images at different loading stages; extract the crack shape in CT scanning images, and perform three-dimensional visualization and quantitative analysis; combine material loading curves, acoustic emission signal characteristics, CT Image the three-dimensional features of cracks, and quantitatively describe the damage evolution of PBX specimen 2 during the loading process.

[0045] Combine below figure 1 , figure 2 , image 3 , Figure 4 The present invention is further descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com