Sewer repairing trolley and sewer pipeline repairing method

A technology for sewers and cement pipes, applied in chemical instruments and methods, pipe components, motor vehicles, etc., can solve problems affecting the personal safety of construction personnel, affecting traffic, and poor working conditions for construction personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

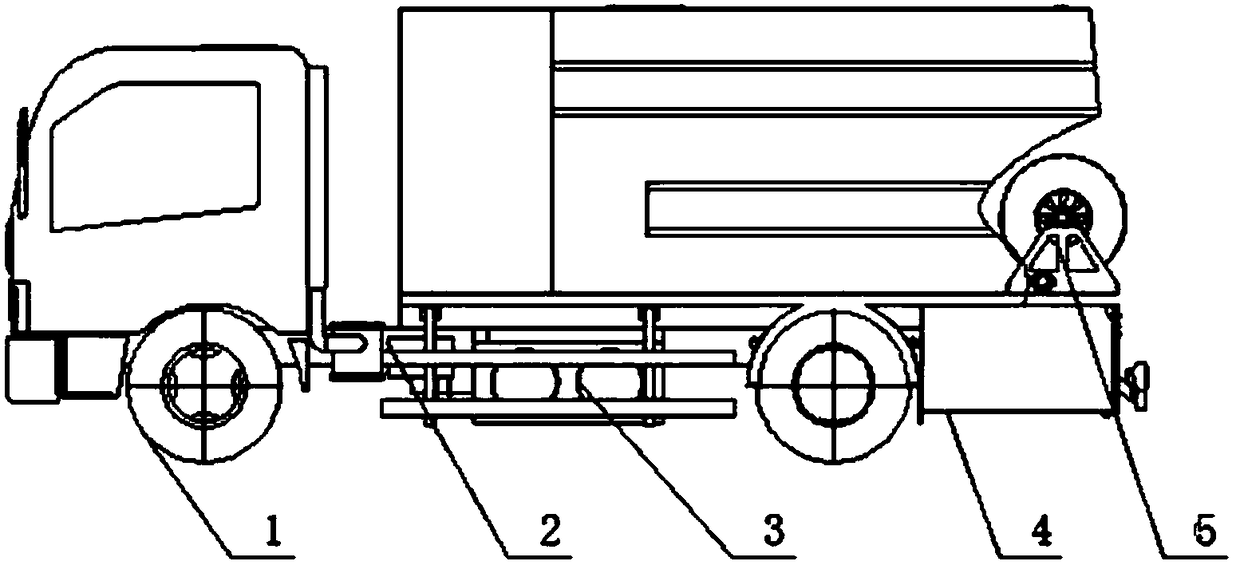

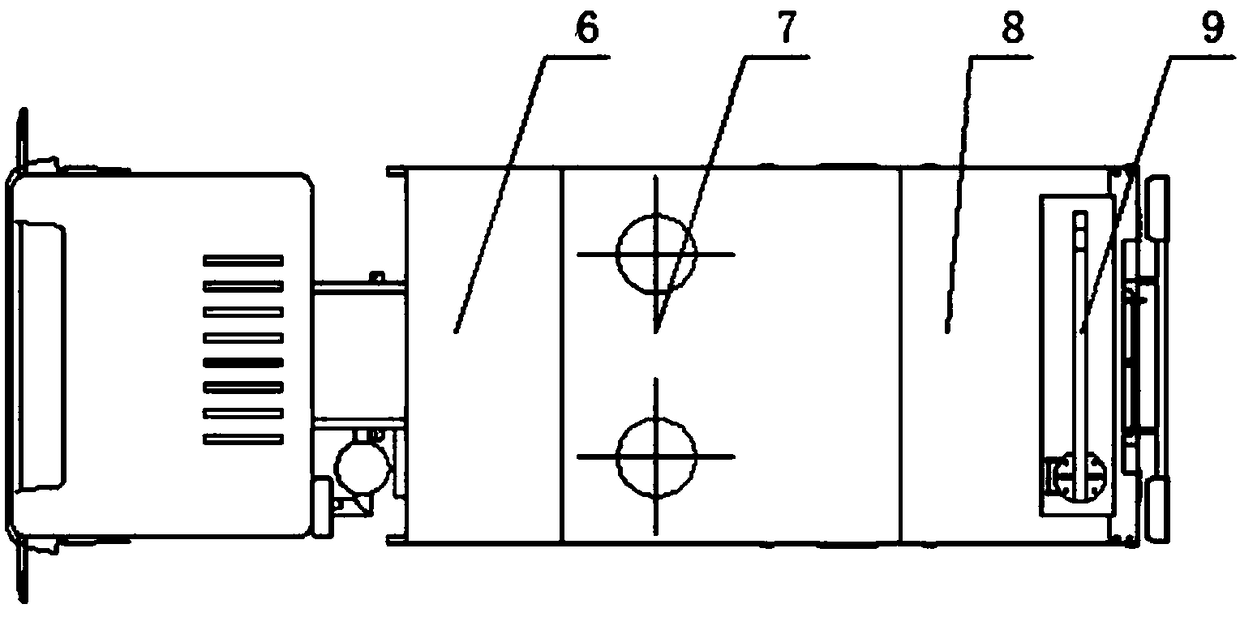

[0033] Such as figure 1 , figure 2 As shown, a sewer repair vehicle includes a chassis vehicle 1, a subframe 2 installed on the chassis vehicle, a hydraulic system 3, a water tank 6 installed on the subframe 2, and a cement slurry preparation system 7. The pipeline robot 10 and the shaper 14 in the sewer, the shaper is connected with the pipeline robot and can rotate around its own central axis and open outward; the rear end of the sub-frame is equipped with a hose reel 5, the The hose reel 5 is wound to control the pipeline robot 10 , the shaper 14 , and the power line pipe 32 for controlling the walking and grouting of the pipeline robot 10 . A box body 8 is installed at the rear of the subframe, and the top of the box body is provided with a boom 9 for hoisting a pipeline robot 10 and a shaper 14 . The bottom of the sub-frame is installed with a placement box 4 for accommodating the pipeline robot 10 and the shaper 14 .

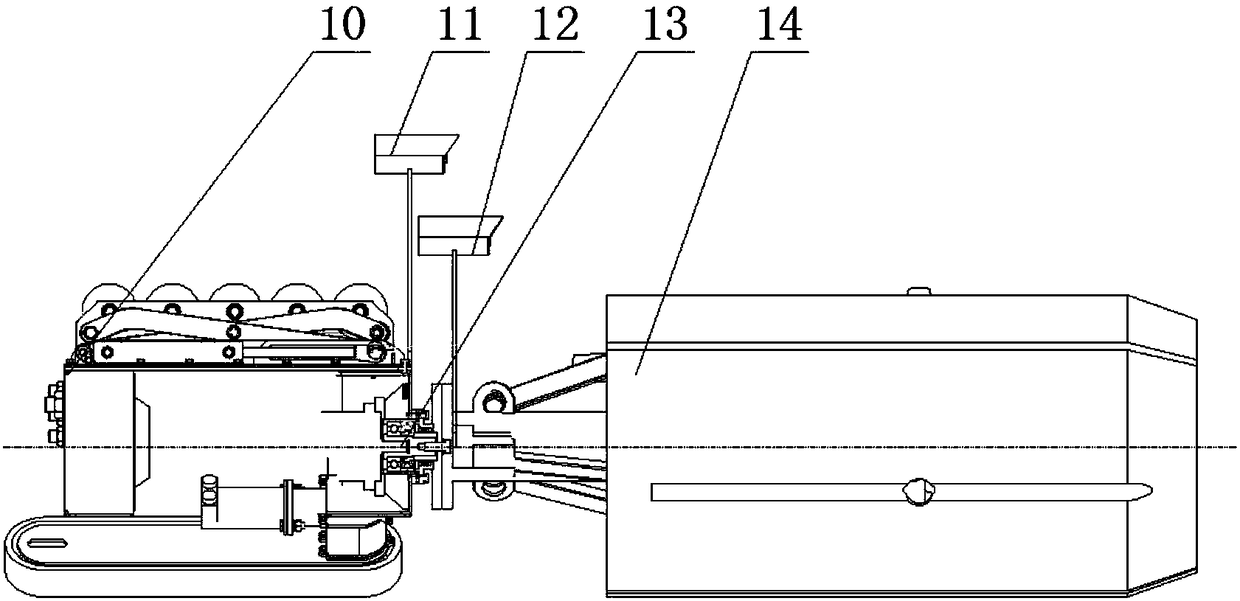

[0034] Such as Figure 3-Figure 5 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com