Safety and wind-resistant metal roofing structure system and installation technology thereof

A metal roofing and roofing system technology, applied in the direction of roofing, building structure, roof covering, etc., can solve the problems of releasing the roof's wind resistance and stress generation, so as to improve the ability to resist external forces, improve stability, and improve resistance The effect of the windbreak problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

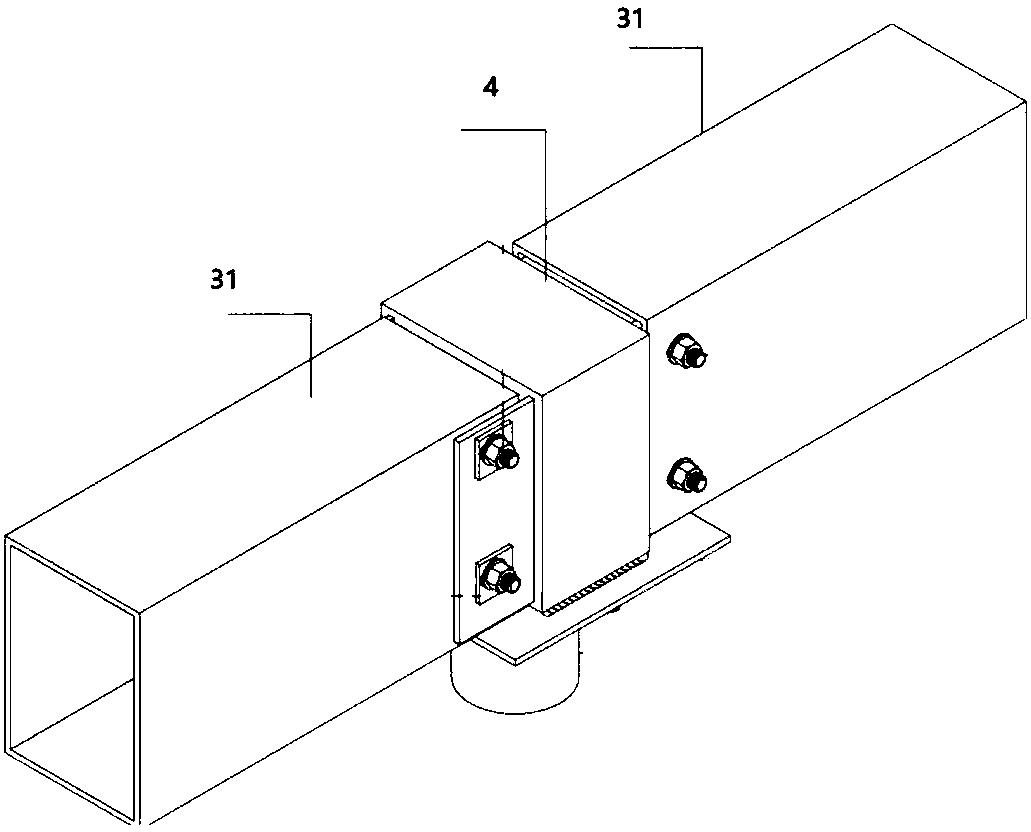

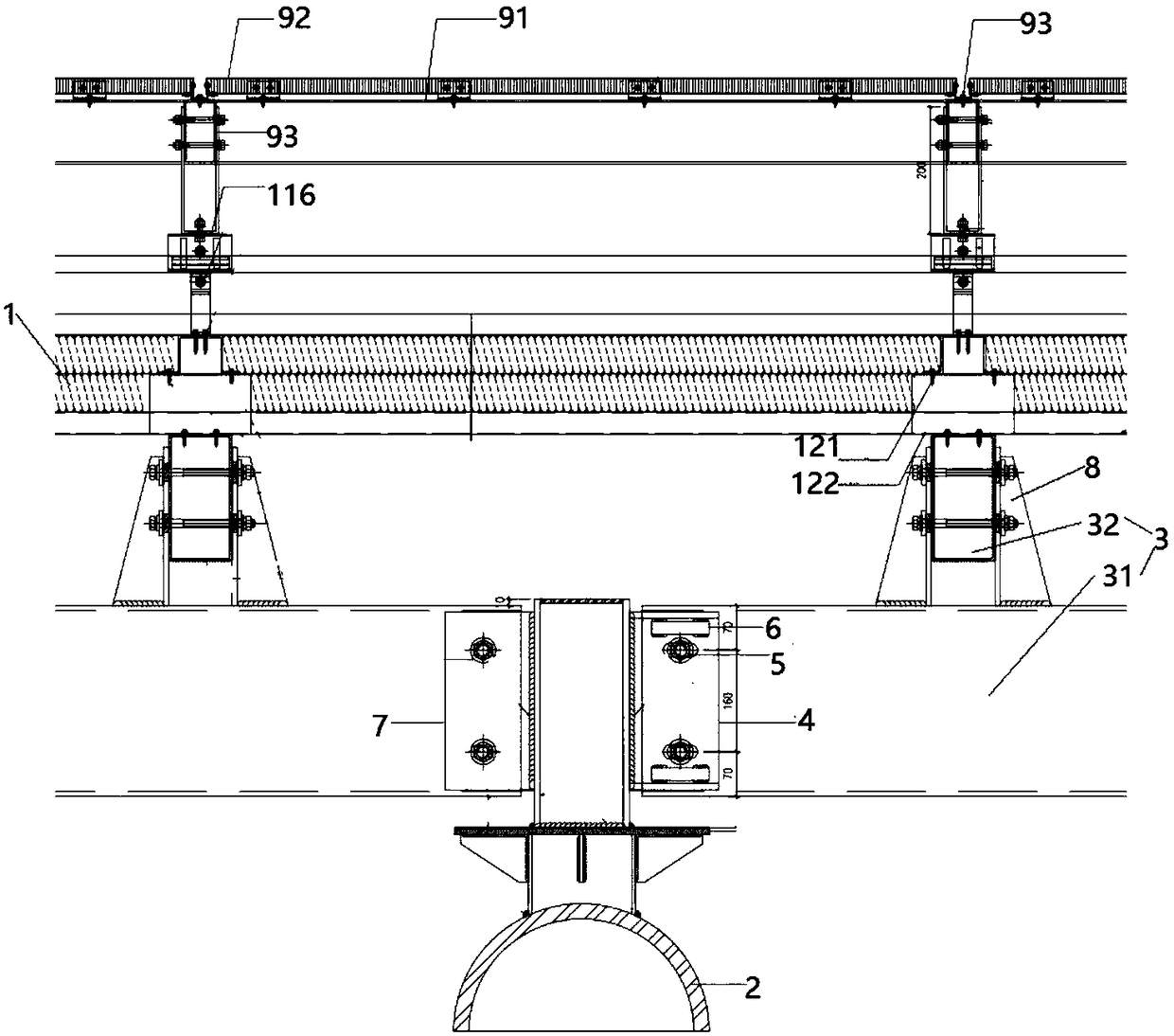

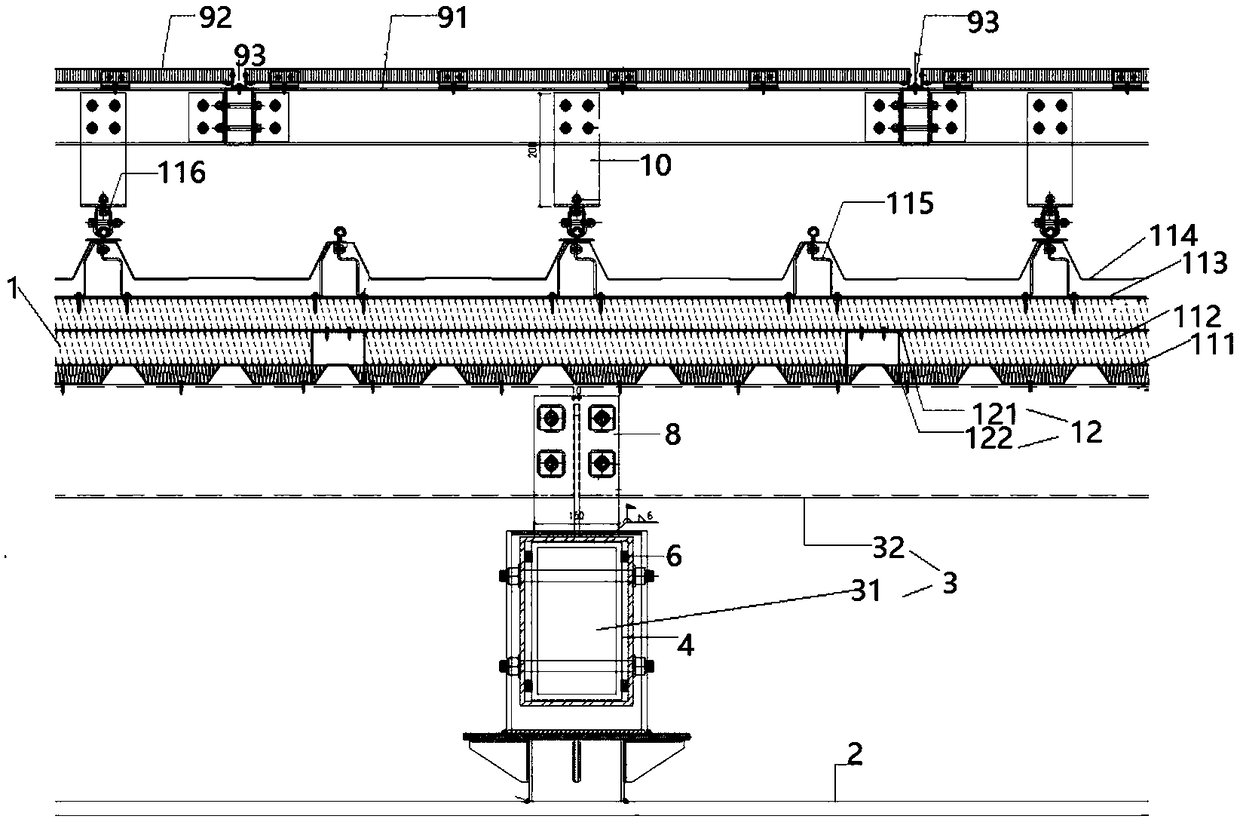

[0031] As shown in the figure, a safe, wind-resistant metal roof construction system includes: a roof system 1, a main steel structure 2 and a roof decoration structure 9, and the roof system 1 is connected to the main steel structure 2 through sandalwood bars 3 , wherein, the main sandal bar 3 is provided with a main sandal bar 31 and a secondary sandal bar 32, and the main sandal bar 31 is arranged on the top of the main steel structure 2, and is connected with the main steel structure 2 through a connecting piece, and The main sandalwood bar 31 is provided with a sleeve 4, and the main sandalwood bar 31 is provided with an oblong hole 5, and the sleeve pipe 4 and the main sandalwood bar 31 are connected through the oblong hole 5 by a bolt assembly, and are connected through the ear plate 6 The two are positioned, a backing plate is provided between the bolt assembly and the oblong hole 5, the sleeve 4 is connected to the main bar 31 through the connecting steel plate 7, and ...

Embodiment 2

[0041] As shown in the figure, a safe, wind-resistant metal roof construction system includes: a roof system 1, a main steel structure 2 and a roof decoration structure 9, and the roof system 1 is connected to the main steel structure 2 through sandalwood bars 3 , wherein, the main sandal bar 3 is provided with a main sandal bar 31 and a secondary sandal bar 32, and the main sandal bar 31 is arranged on the top of the main steel structure 2, and is connected with the main steel structure 2 through a connecting piece, and The main sandalwood bar 31 is provided with a sleeve 4, and the main sandalwood bar 31 is provided with an oblong hole 5, and the sleeve pipe 4 and the main sandalwood bar 31 are connected through the oblong hole 5 by a bolt assembly, and are connected through the ear plate 6 The two are positioned, a backing plate is provided between the bolt assembly and the oblong hole 5, the sleeve 4 is connected to the main bar 31 through the connecting steel plate 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com