Electrospinning fiber injection device with controllable injection environment and control method of injection environment

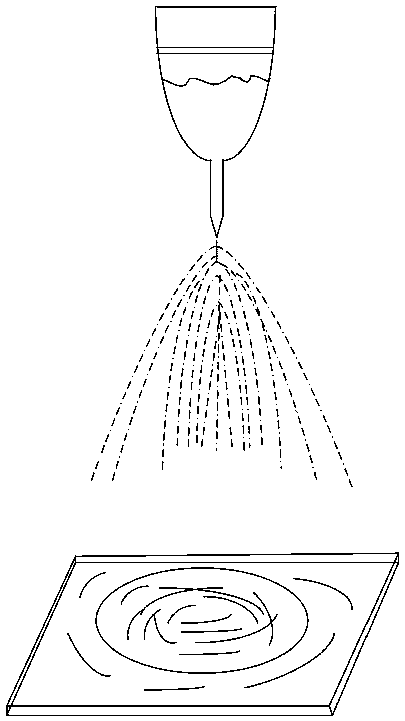

A technology of electrospun fiber and injection device, which is applied in fiber processing, textile and papermaking, and filament generation, etc. It can solve the problems of high-quality production or research of electrospun fibers, lack of reliability, stability of environmental parameters, and complex equipment structure, etc. problem, to achieve the effect of simple installation, wide application range and good observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

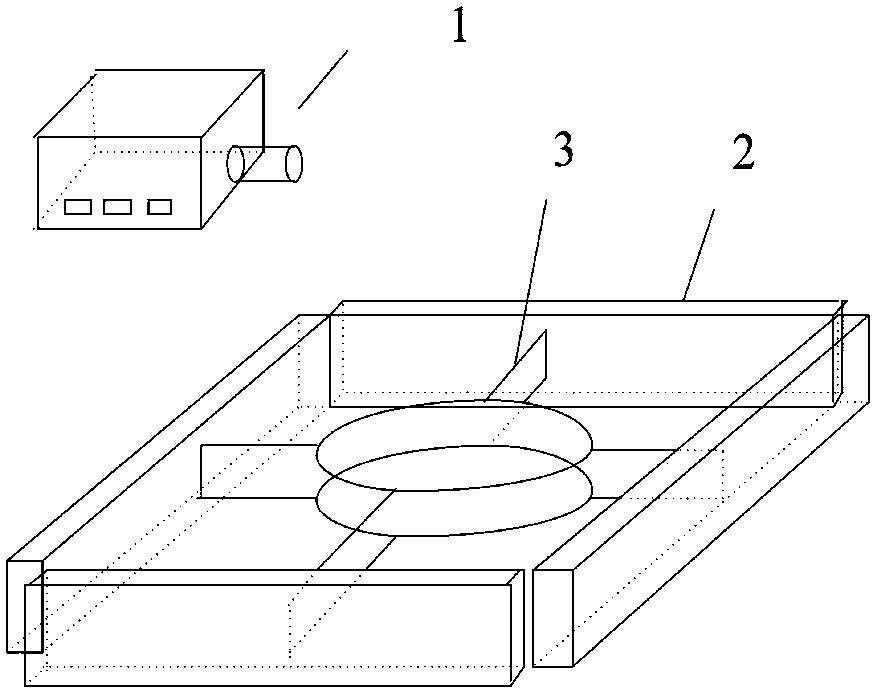

[0012] Embodiment 1: In order to solve the convenient, accurate, reliable and low-cost control of the temperature and humidity of the electrospun fiber jetting environment, this embodiment provides a combined electrospun fiber jetting environment control device based on a controllable air flow. The device consists of a constant temperature Composed of constant humidity air source, bracket, blowing slot, suction slot, filter screen, and suction fan.

[0013] Wherein: the constant temperature and constant humidity air source can output air with adjustable temperature and humidity, and the air flow is controllable. The constant temperature and constant humidity air source is a common device in the field of automatic control.

[0014] The blowing grooves are connected to the four blowing grooves by the above-mentioned constant temperature and humidity air source, the blowing grooves control the air flow to blow downward at a certain angle, and the four blowing grooves are installed...

Embodiment 2

[0021] Embodiment 2: A combined electrospun fiber injection environment control device based on controllable airflow, including a blowing groove and a suction groove, the described blowing groove is a closed and hollow support frame, and the blowing groove is The hollow layer is connected to the constant temperature and humidity blower to enter the hollow layer of the blowing groove, and the side wall of the support frame is used as a guiding device for air intake to form an air curtain. The described blowing groove is correspondingly provided with a suction groove, and the suction groove It is an enclosed and hollow support frame, in which the hollow layer is connected to the suction fan, and the air curtain formed by the blowing groove is discharged by the suction fan through the suction groove. From the above, an air curtain for the air flow between the blowing groove and the suction groove is formed, so that the spray environment is formed to form a closed space, and the ai...

Embodiment 3

[0036] Embodiment 3: a kind of electrospun fiber injection device with controllable injection environment, as an independent embodiment or as the embodiment of the scheme in embodiment 2, the described blowing slot is made up of four rectangular support frames, which The four rectangular support frames are connected through the left and right side walls to form an integrated or separate connection, the upper side wall of each rectangular support frame communicates with the blowing groove, and the inner side wall and the outer side wall are closed walls. Yet at least one inner wall of four rectangular bracing frames has a transverse air outlet, and the lower side wall has an air outlet, and the air curtain is sent out from the air outlet, wherein the inner wall of a rectangular support of the air blowing groove is opened. Out of the horizontal air outlet.

[0037] In one solution, the lower position of the inner wall of the rectangular support frame opposite the horizontal air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com