Semi-open type water bearing plug-flow aerator

A water bearing, semi-open technology, applied in water aeration, water treatment parameter control, water/sludge/sewage treatment, etc., can solve the problems of unreasonable transmission parts in water, inconvenient assembly and disassembly, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the invention will be further described below in conjunction with the accompanying drawings:

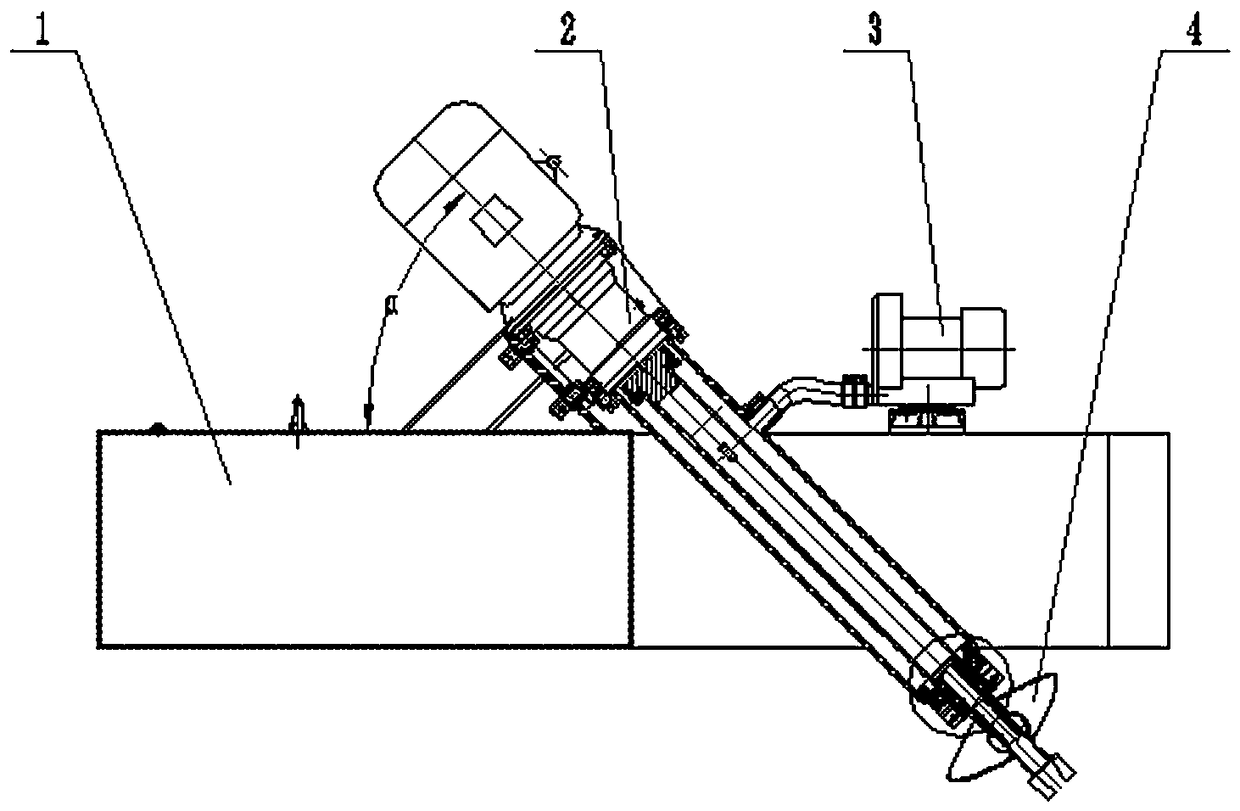

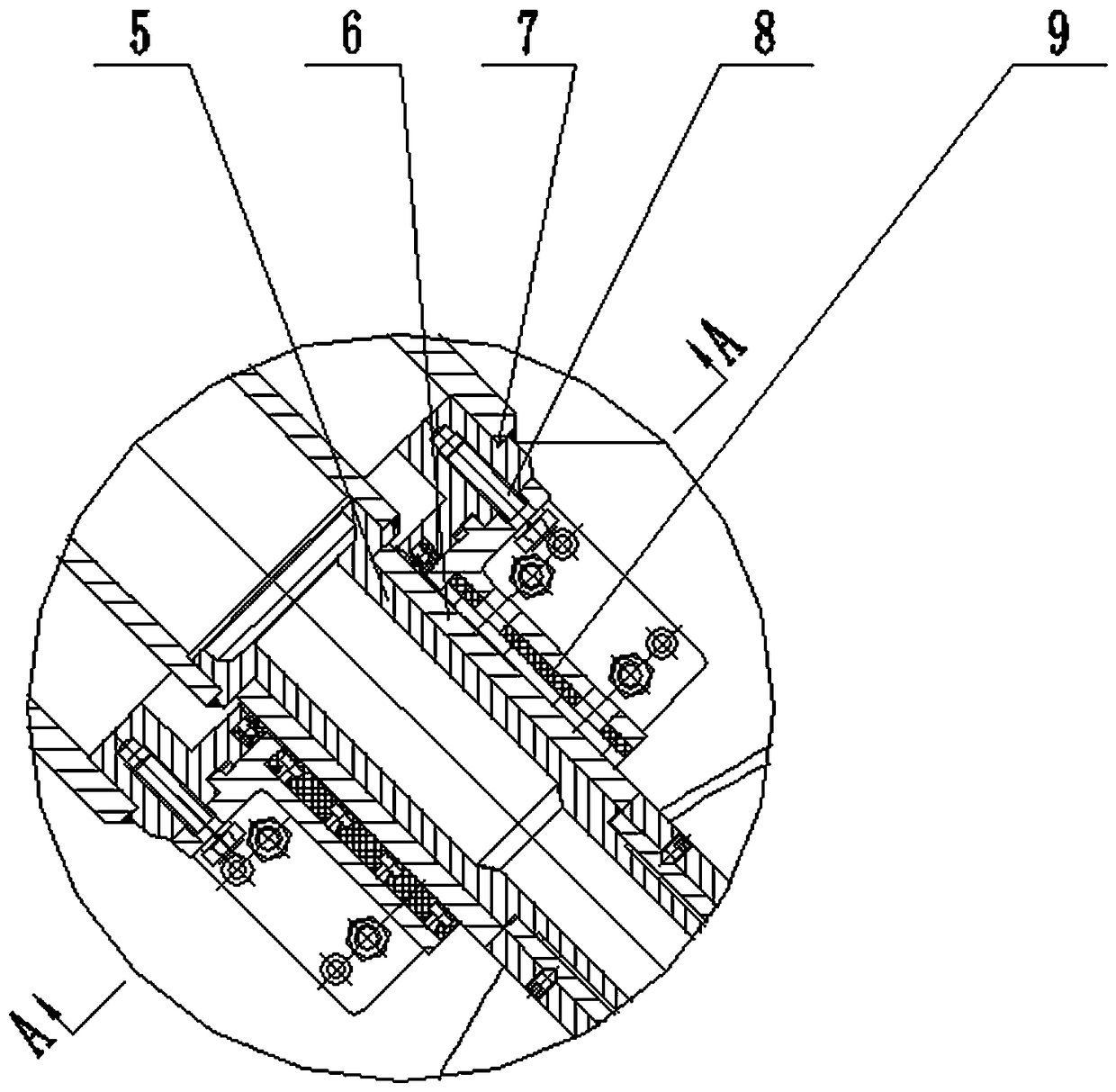

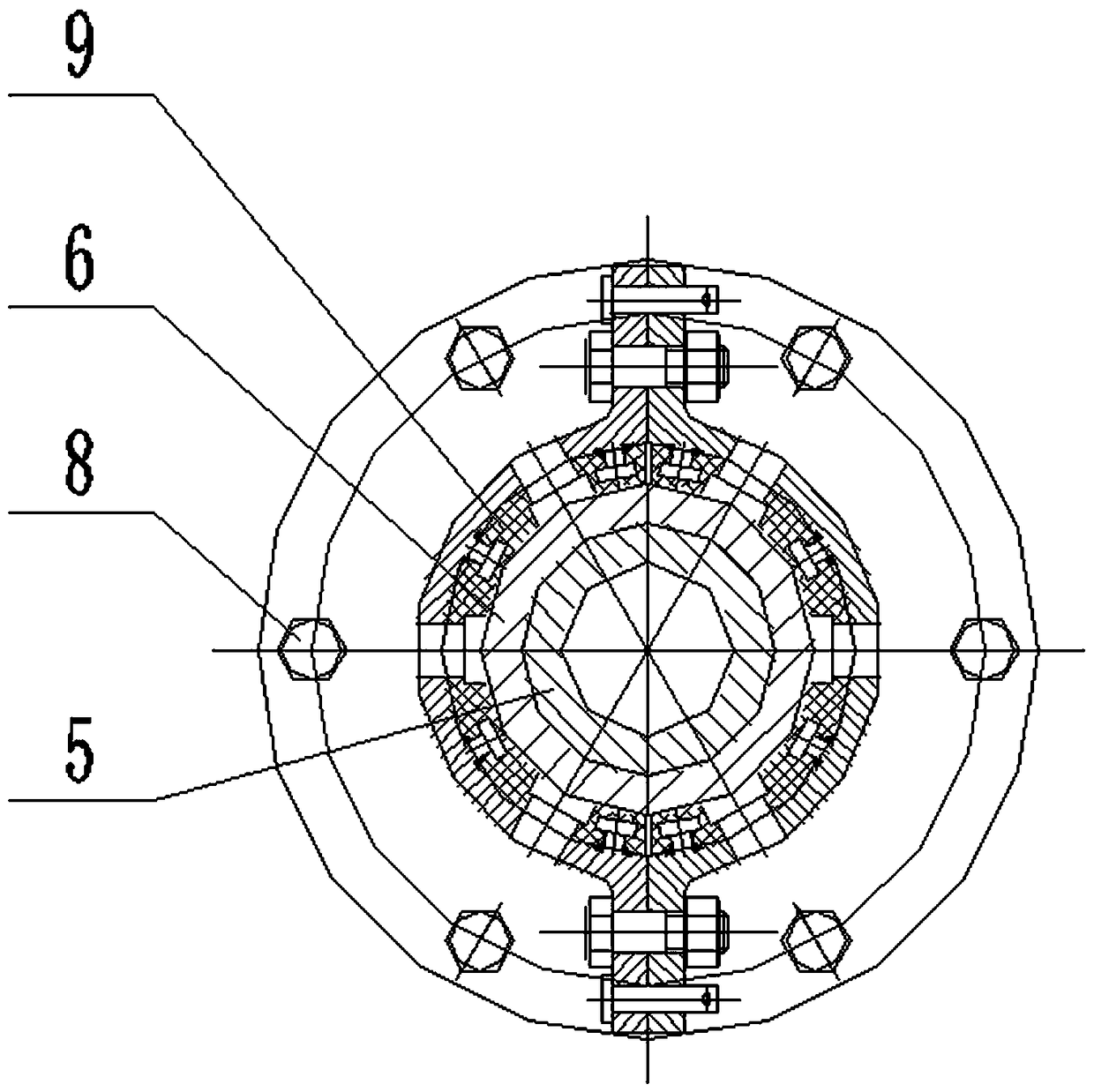

[0017] Figure 1-6 As shown, a semi-open water bearing plug-flow aerator includes a support body 1, a drive push-flow device 2, a blower 3, and an impeller 4. The drive push-flow device 2 is installed and fixed at the middle of the support body 1 at an angle of α. , the blower 3 is installed on the support body 1 and connected to the hollow support tube and the hollow transmission shaft in the coaxial gap socket in the middle of the driving push flow device 2, and is pressed out through the bottom of the hollow transmission shaft. The lower part of the hollow transmission shaft is connected to the impeller 4, and the hollow transmission shaft The lower part is the water bearing part 5 of the hollow drive shaft, the impeller is connected to the lower part of this part, the upper part of this part is set with a semi-open water bearing through the water bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com