Method for synthesizing gaphene by carbon oxide-assisted chemical vapor phase deposition

A chemical vapor deposition, oxide-assisted technology, applied in the direction of graphene, nano-carbon, etc., can solve problems such as the decrease of nucleation density and the enhancement of oxygen atom etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] In this example, a copper foil with a purity of 99.998% and a thickness of 25 µm was used as the substrate.

[0033] 1. Trial experiment:

[0034] First, put the cut copper foil into the electrochemical polishing device, use the copper foil as the anode and the graphite as the cathode, and polish it with a voltage of 1.5V-2.0V for 10 minutes. After taking it out, rinse it with deionized water and use nitrogen with a purity of 99%. blow dry. The polished copper foil is heated in air at 180°C~220°C for 4~10 minutes to oxidize it.

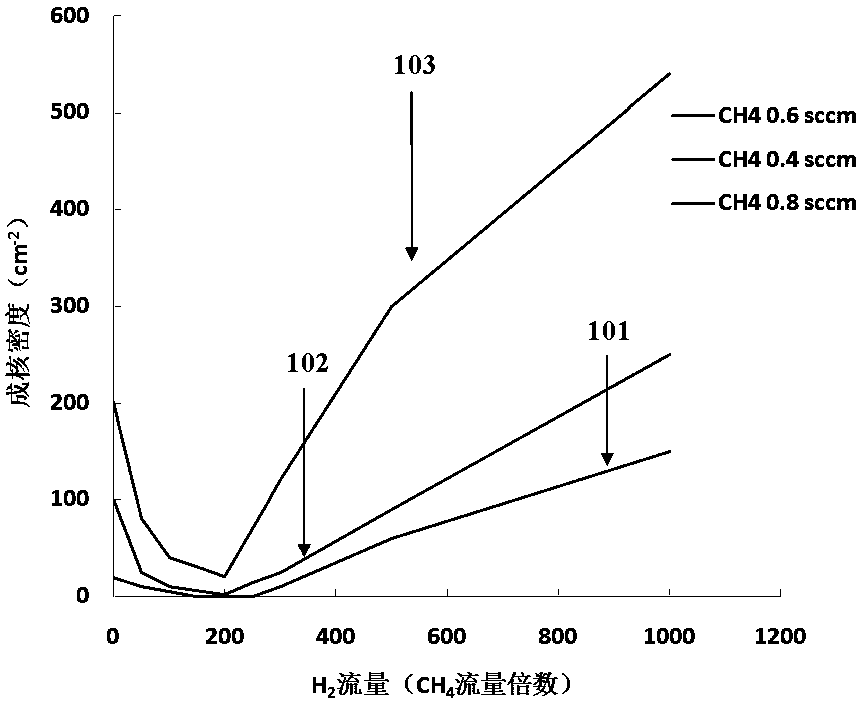

[0035] Put the oxidized copper foil substrate into the furnace chamber of the chemical vapor deposition system, and then vacuumize the furnace chamber. Introduce 100 sccm of argon gas into the furnace chamber, and start to raise the temperature of the furnace chamber at the same time. After the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com