Paper receiving device for corrugated paperboard

A technology of corrugated cardboard and paper splicing mechanism, which is applied in the direction of stacking receiving device, transportation and packaging, thin material processing, etc. It can solve the problems of paper splicing confusion, failure to meet rapid production, and inability to quickly retract and unwind, etc., to achieve fast paper splicing Retractable, high stability, to meet the effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

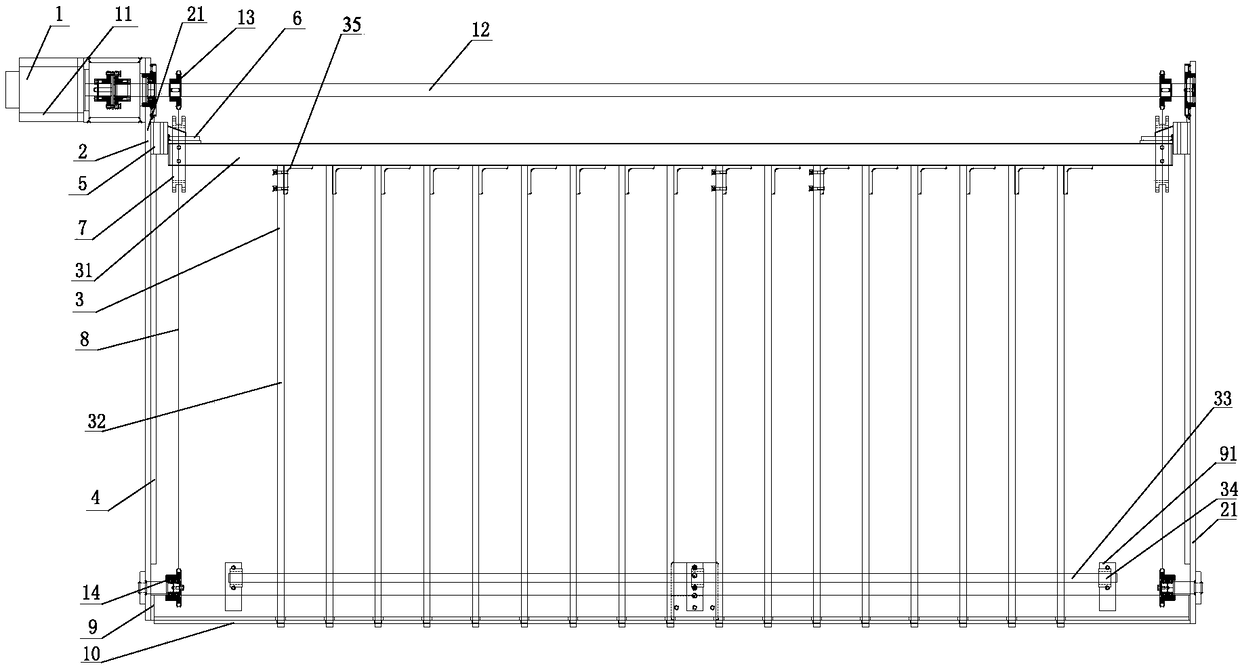

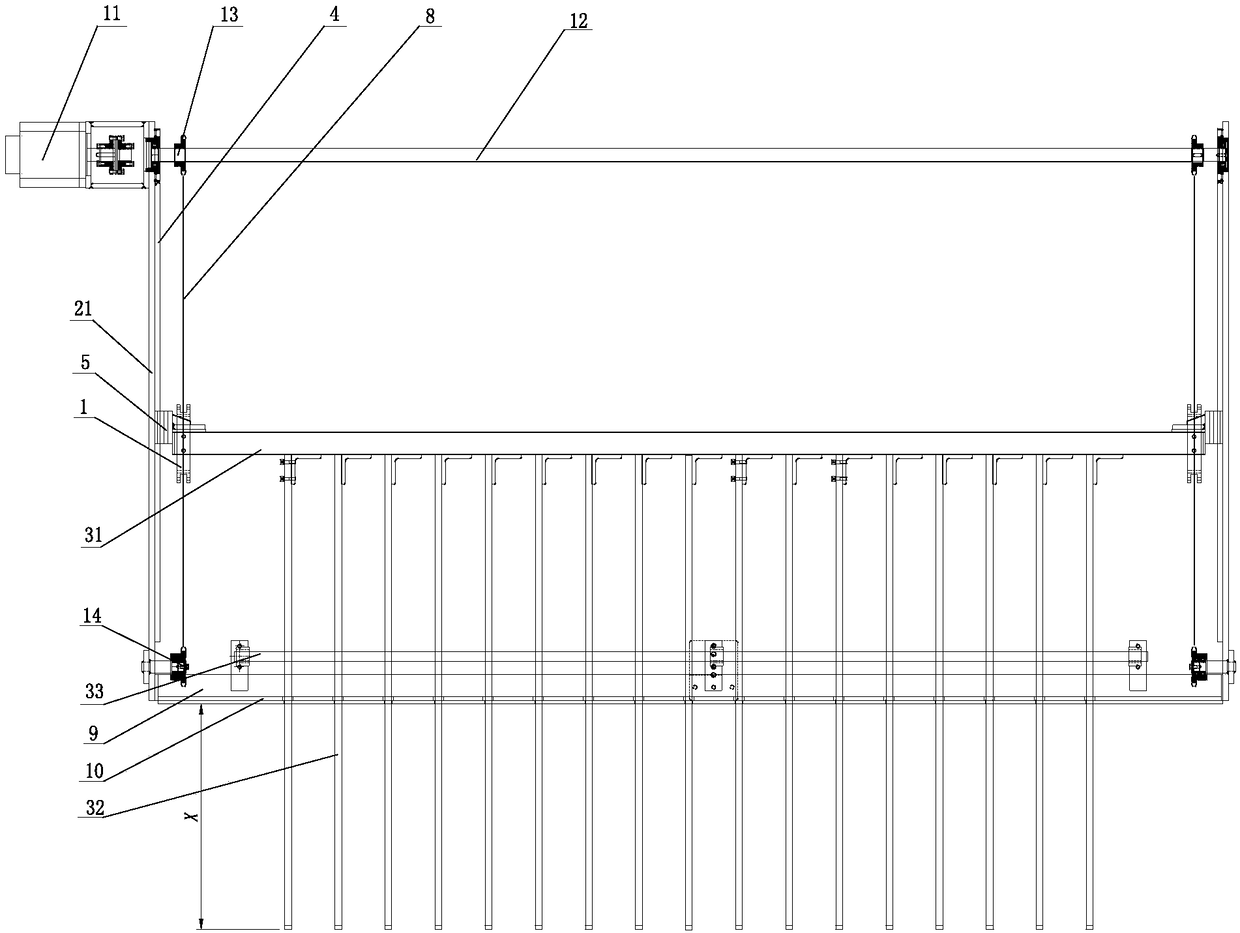

[0016] like figure 1 and figure 2 As shown, a paper splicing device for corrugated cardboard includes a paper splicing transmission mechanism 1, a support mechanism 2 and a paper splicing mechanism 3. The paper splicing transmission mechanism 1 is installed on the upper part of the support mechanism 2, and the support mechanism 2 is left and right. A symmetrical structure composed of parts, the inner side of the left and right parts of the support mechanism 2 are provided with a linear slide rail 4, the linear slide rail 4 is provided with a linear slider 5, and the paper receiving mechanism 3 includes the upper paper receiving rod beam 31 and Several paper rods 32 fixed below the paper rod beam 31, the two ends of the paper rod beam 31 are fixedly connected with the linear slider 5 through the connecting block 6, and the two ends of the paper rod beam 31 are also fixed with chain connecting plates 7. The paper receiving transmission mechanism 1 is connected with the chain c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com