Preparation method of durable heat preservation container and heat preservation container prepared by using same

A thermal insulation container, a durable technology, applied in the field of thermal insulation containers, vacuum insulation containers, can solve the problems of non-durability, poor airtightness, cracking of glass glue, etc., achieve high yield, reduce the probability of vacuum leakage, and durable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

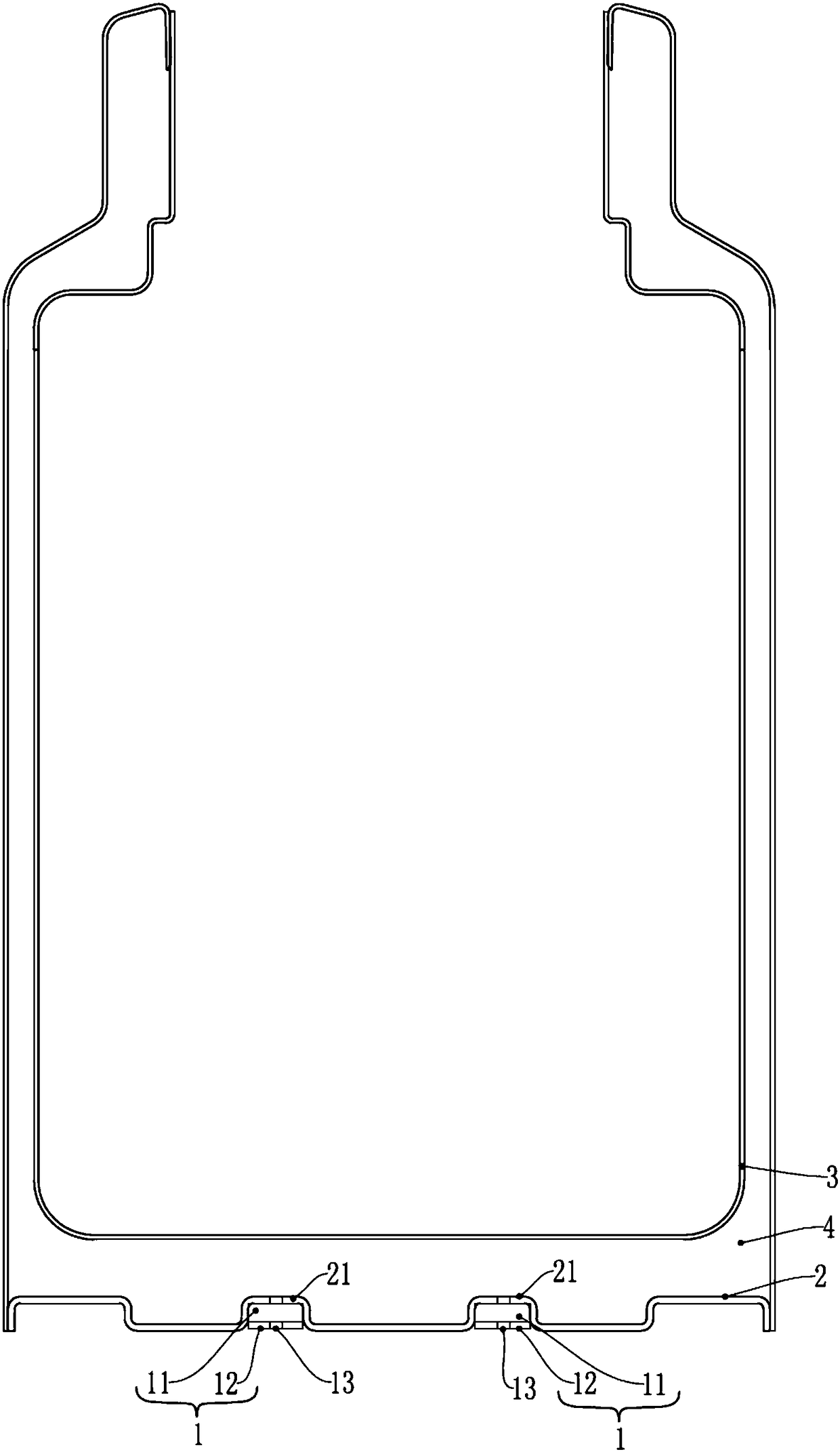

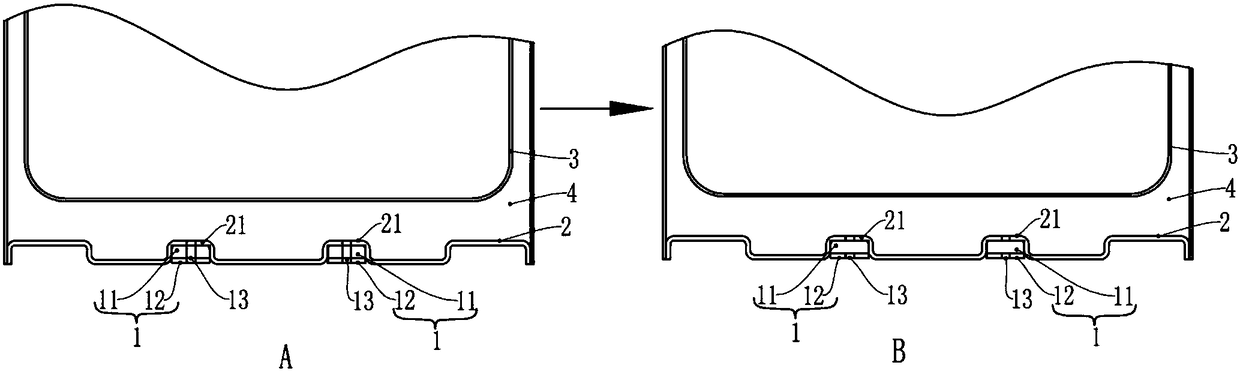

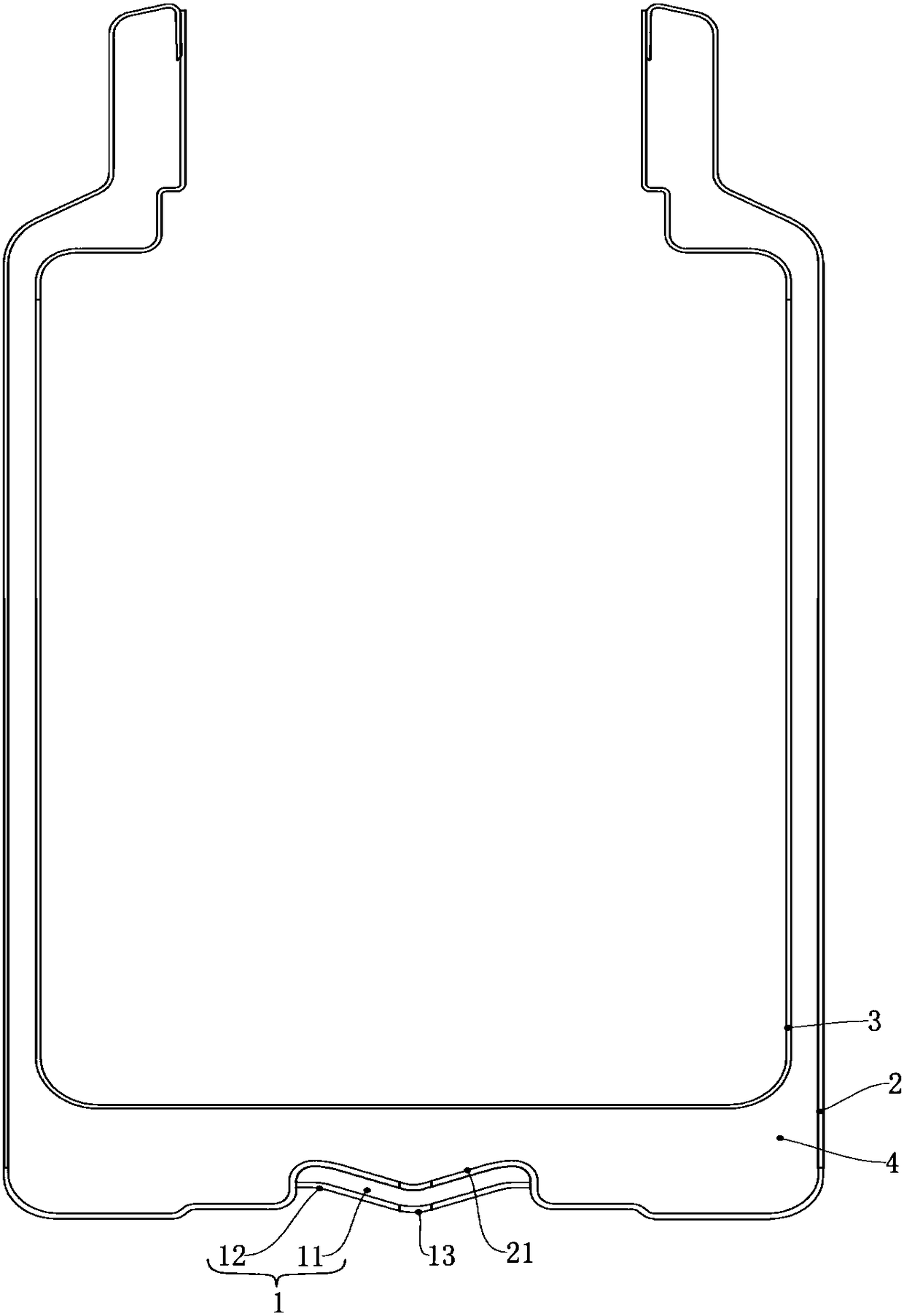

[0046] The durable insulation container preparation method of the present embodiment, as figure 1 As shown, the heat preservation container is a heat preservation container formed by vacuumizing between the outer shell 2 and the inner shell 3 made of metal, and a sealed vacuum heat preservation cavity 4 is formed between the outer shell 2 and the inner shell 3. The preparation The method includes the following steps:

[0047] Step A, prepare the auxiliary part 1, the auxiliary part 1 is formed by stacking the low-temperature sealing layer 11 and the high-temperature covering layer 12 and welding each other, and the low-temperature sealing layer 11 is made of metal that will melt at the melting temperature, so The high-temperature covering layer 12 is made of a metal that will not melt at the meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com