Driving wheel mechanism and driven wheel mechanism

A technology of driving wheels and driven wheels, which is applied in motor vehicles, tracked vehicles, transportation and packaging, etc., can solve problems such as track lateral movement, track falling off, and affecting equipment reliability, so as to reduce the occurrence rate and have a good guiding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with specific embodiments.

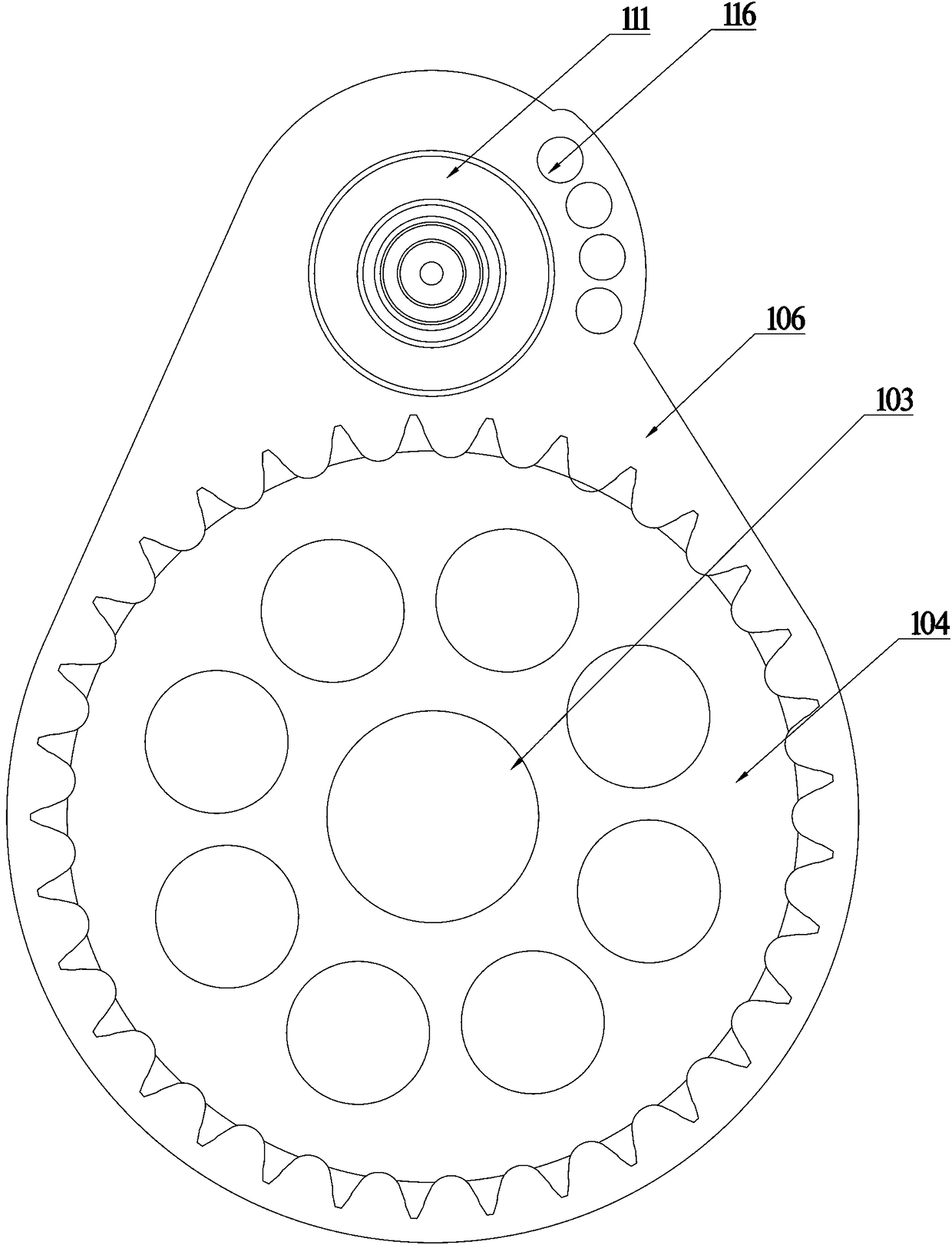

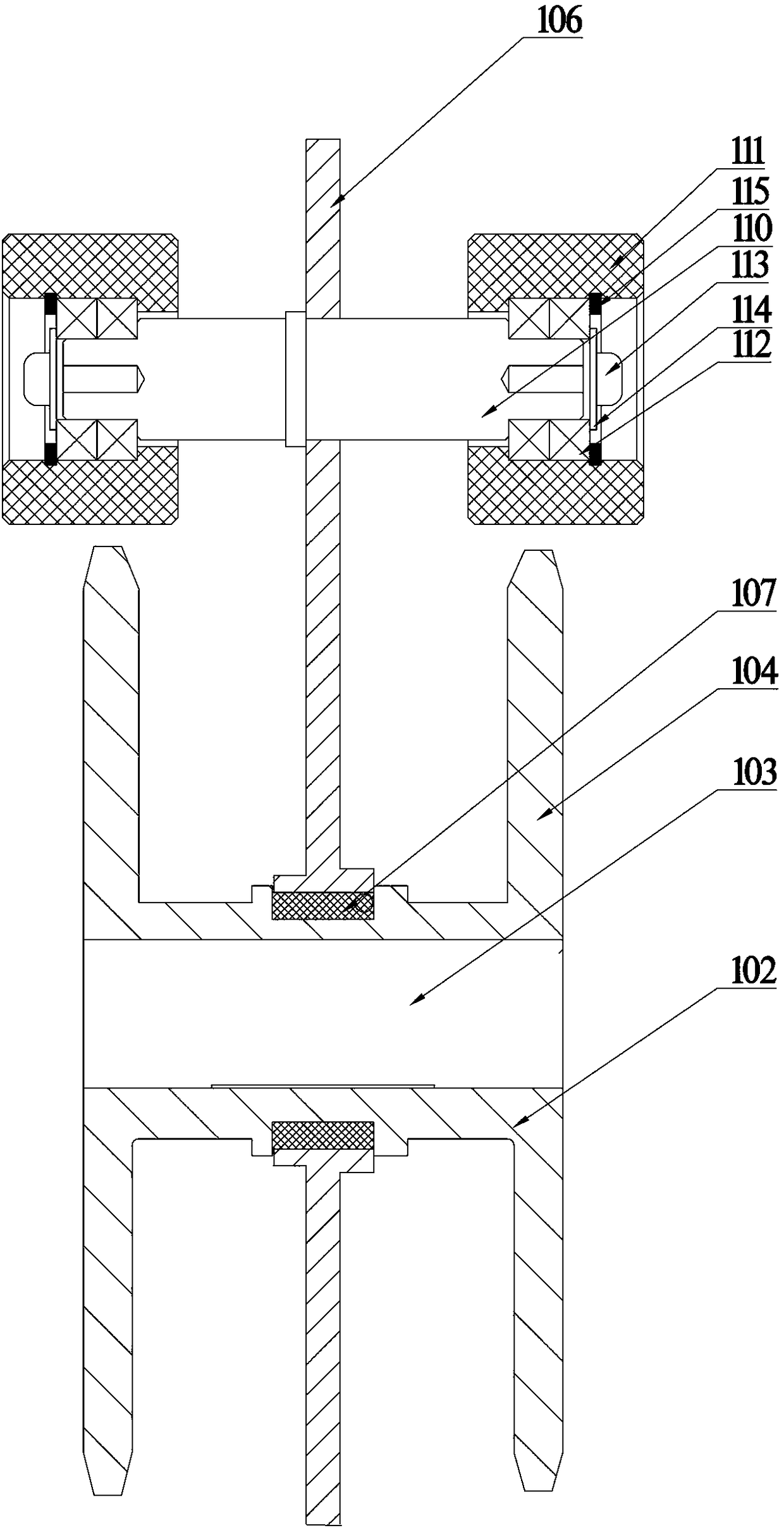

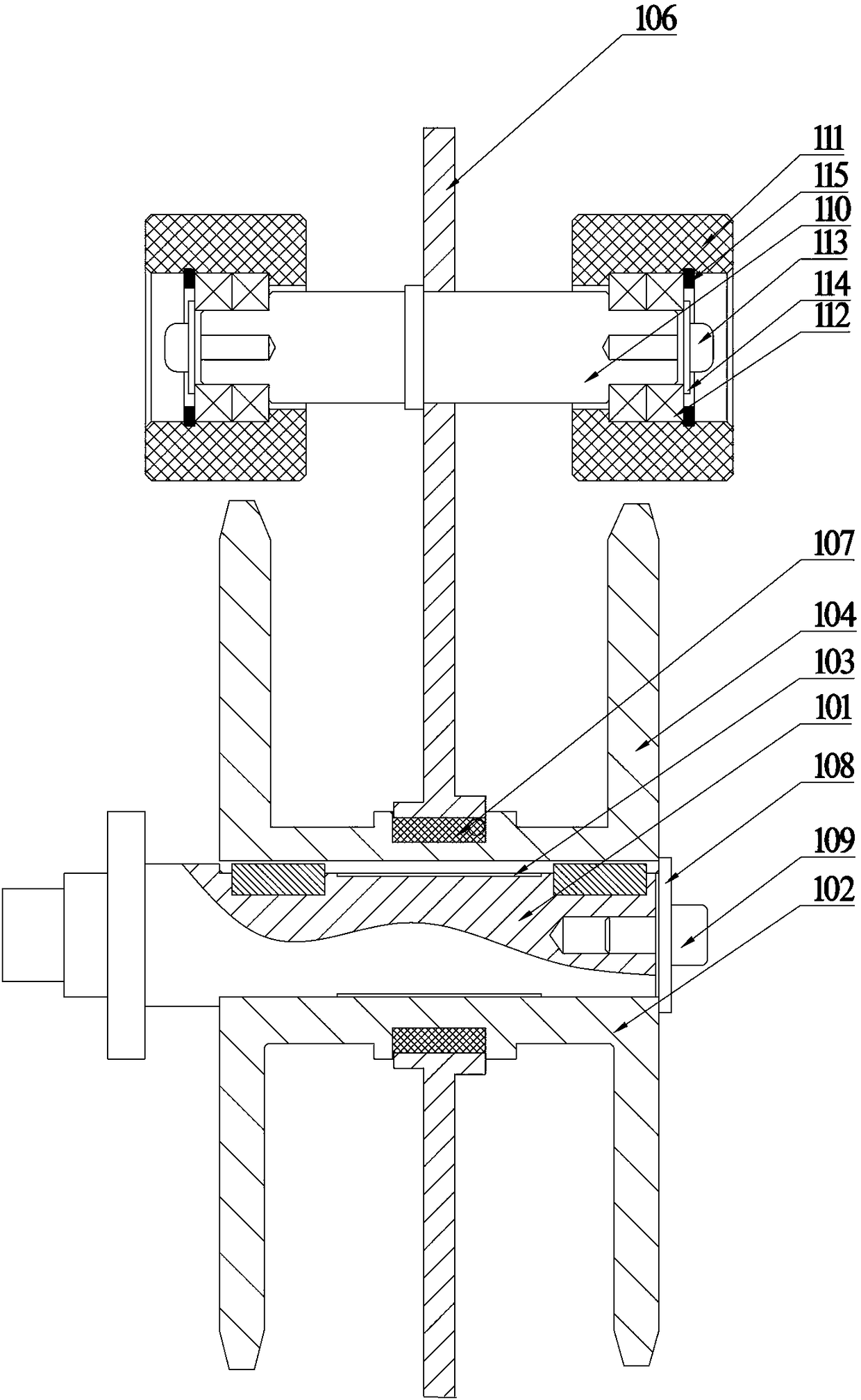

[0032] as attached figure 1 and 2 A kind of drive wheel mechanism shown, it comprises drive sprocket 100, and described drive sprocket comprises drive sprocket body 102, and the axle center of described drive sprocket body 102 is provided with drive shaft hole 103, and described drive sprocket The body 102 is provided with more than two driving sprocket discs 104, in this embodiment, two driving sprocket discs 104, and a driving guide plate 106 is arranged between the two driving sprocket discs 104, and the driving guide plate 106 It forms a rotation fit with the drive sprocket body 102 , and a copper sleeve 107 is installed between the drive guide plate 106 and the drive sprocket body 102 , which reduces the rotation resistance.

[0033] The driving guide plate 106 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com