Worktable capable of adjusting lifting

A workbench and table top technology, applied in the field of mechanical devices, can solve problems such as inability to lift, inconvenient for staff, troublesome adjustment process, etc., to achieve the effect of facilitating work, improving practical applicability, and enhancing structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

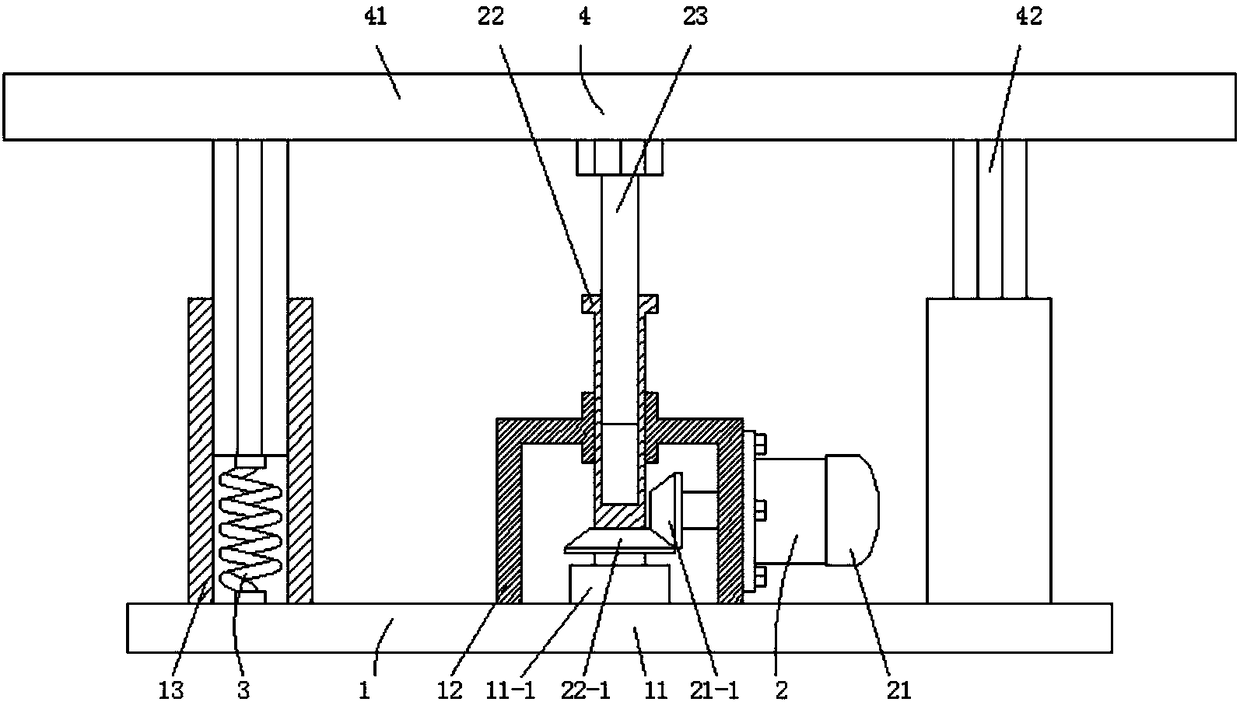

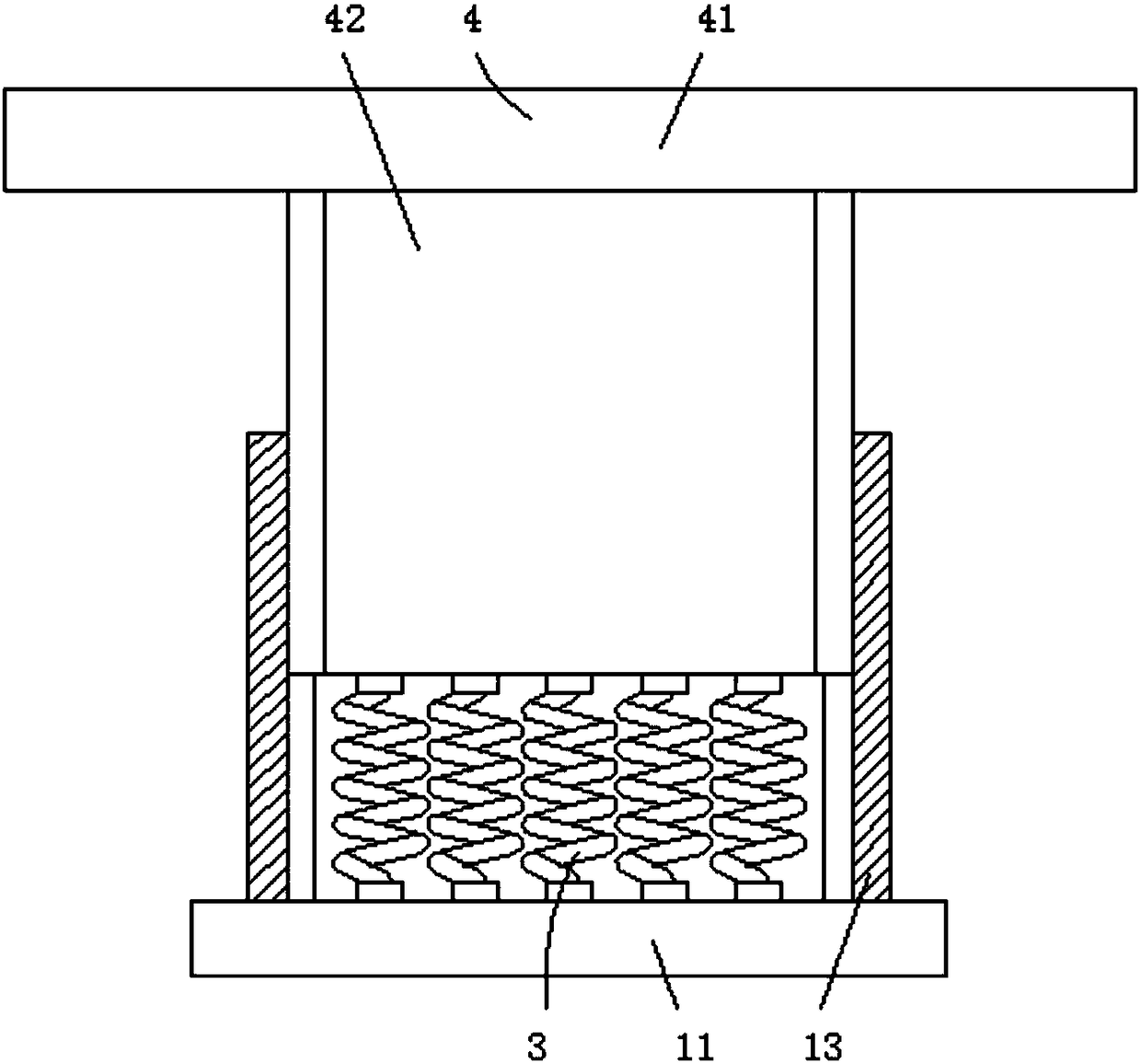

[0012] figure 1 and figure 2 The specific embodiment of the present invention is shown: a lifting and adjustable workbench, including a base assembly 1, a lifting mechanism 2, a spring 3 and a table assembly 4, the base assembly 1 includes a bottom plate 11, a transmission box 12 and a sliding guide column 13, The transmission box 12 is fixedly installed in the center of the base plate 11, and the sliding guide column 13 is provided with two, all fixedly mounted on the base plate 11, and symmetrically distributed relative to the central axis of the base plate 11, and the lifting mechanism 2 is composed of a motor 21 and The internal thread sleeve rod 22 is composed of, the motor 21 is fixedly installed on the side end of the transmission box 12, the output shaft of the motor 21 is connected with the side end of the transmission box 12 in rotation, and the output shaft end of the motor 21 is fixedly equipped with a drive Bevel gear 21-1, the internal thread sleeve rod 22 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com