Motorcycle gear shot blasting tool

A motorcycle and gear technology, applied in the field of motorcycle gear shot blasting tooling, can solve problems such as gears being easily knocked off by steel shot, unclean product shot blasting, bump marks on the surface, etc. The effect of bumping and preventing bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

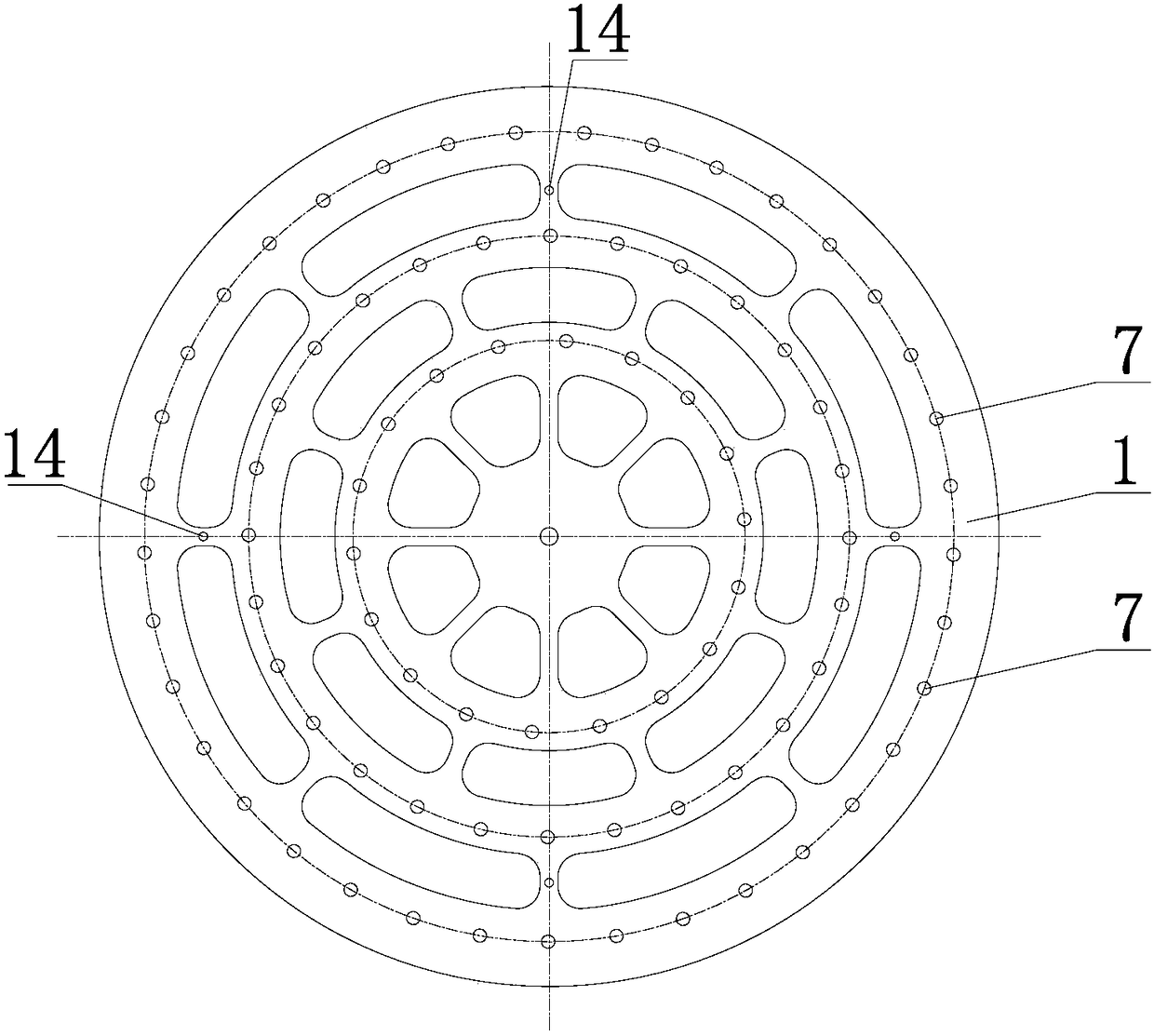

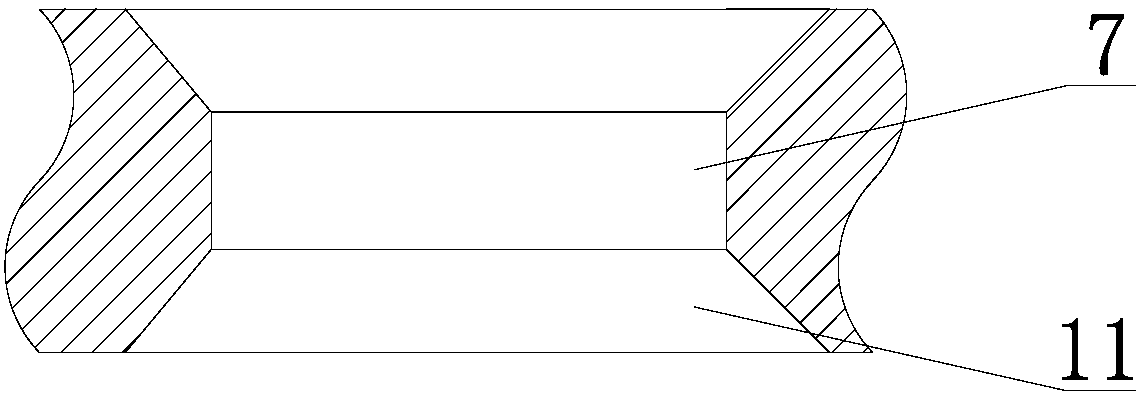

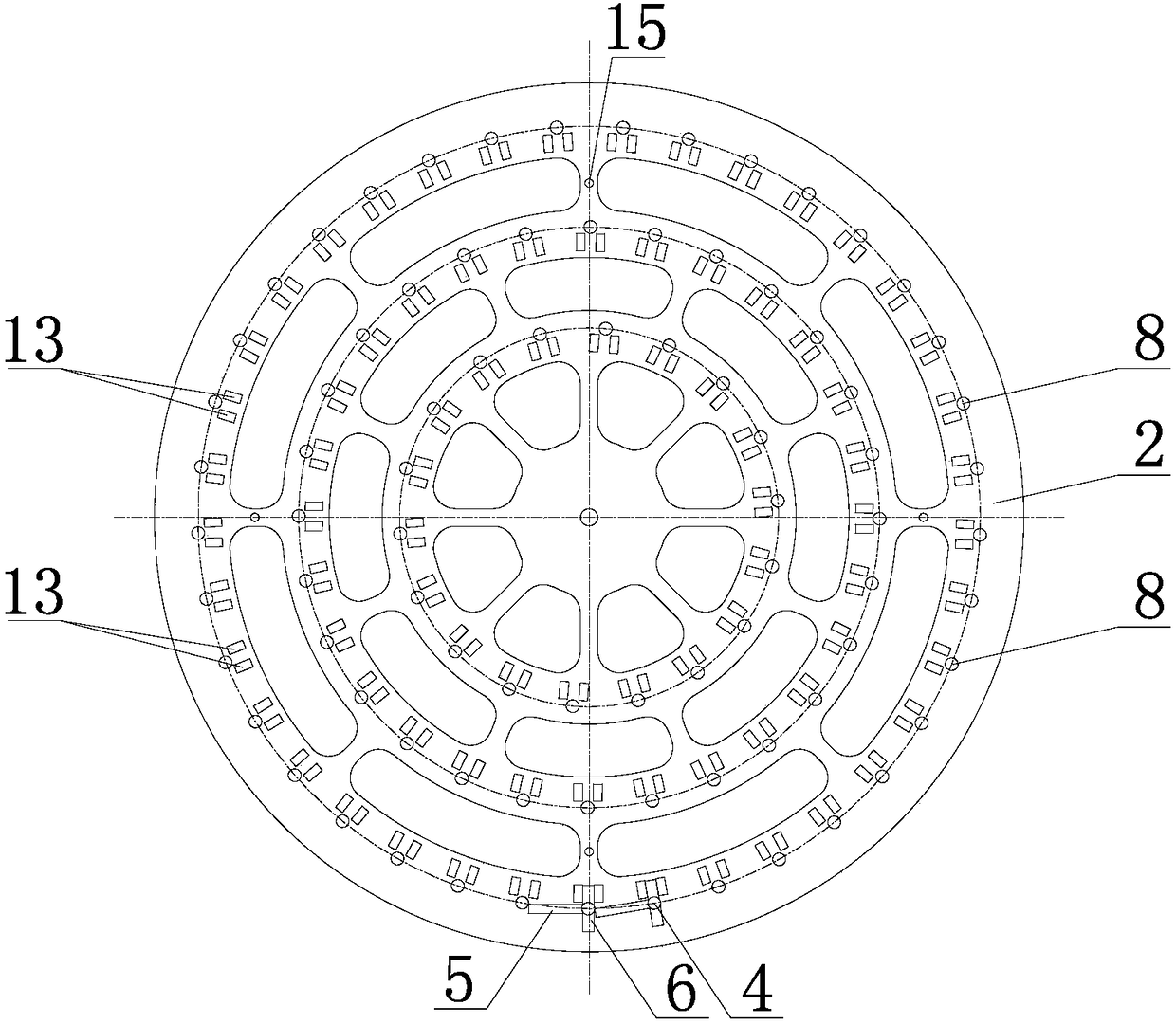

[0031] Such as Figure 5 The motorcycle gear shot blasting tool shown includes a circular upper chassis 1, a circular lower chassis 2 and a support column 3 arranged between the upper chassis 1 and the lower chassis 2, and the upper chassis 1 and the lower chassis 2 Coaxially arranged, there are four support columns 3 and they are distributed in a circular array along the central axis of the lower chassis 2 . Such as figure 1 with image 3 As shown, between the upper chassis 1 and the lower chassis 2, at least one layer of combined hook rings composed of several combined hooks is provided. fixed structure.

[0032] Such as figure 1 with image 3 As shown, there are three tiers of combination hook loops: an outer comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com