Full-automatic intelligent control electric steel pipe cutting machine device

An intelligently controlled and fully automatic technology, applied in the direction of pipe shearing device, shearing device, positioning device, etc., can solve the problems of steel pipe clamping, complex structure, low intelligence of cutting equipment, etc., to reduce the burden on workers and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

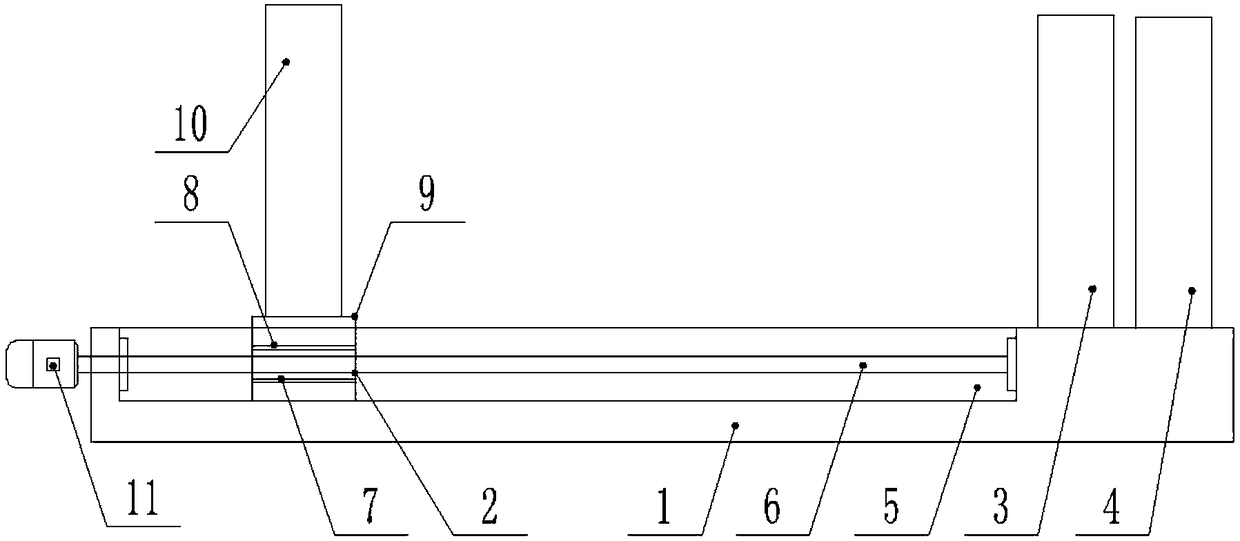

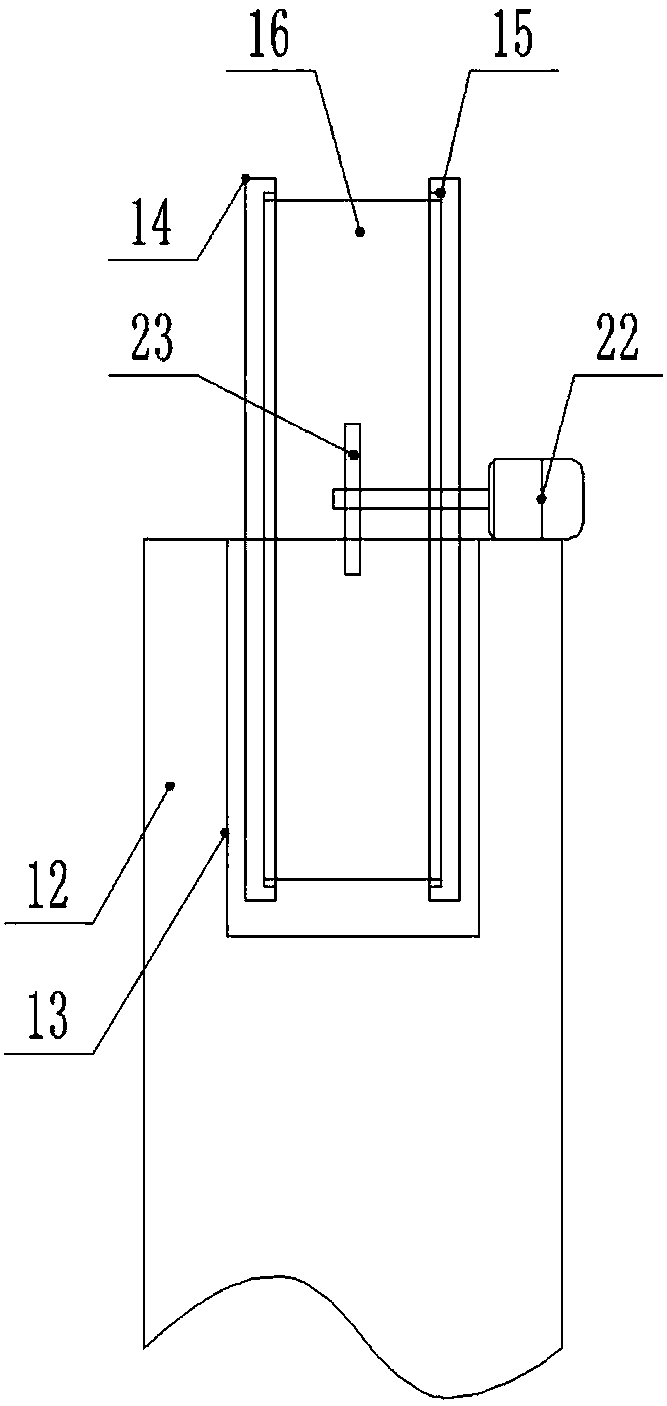

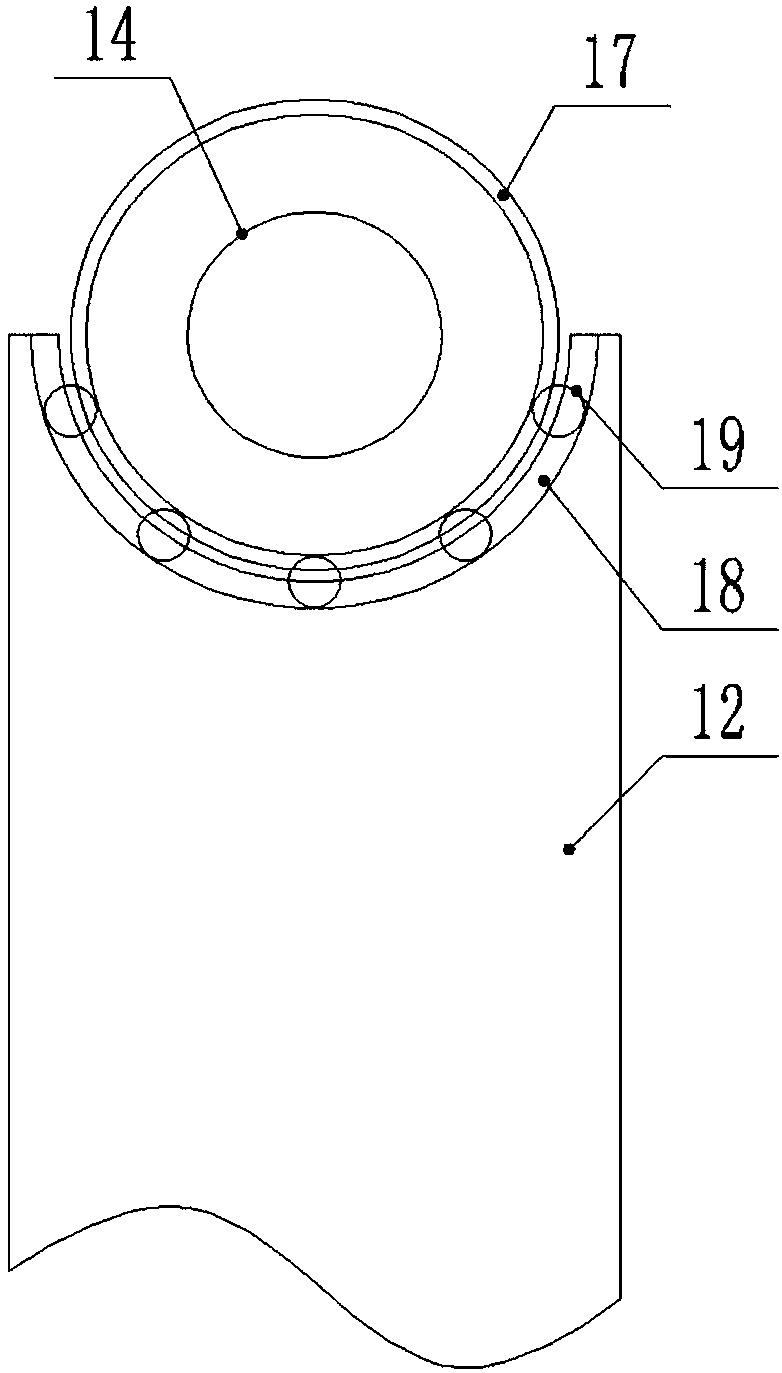

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8As shown, a fully automatic and intelligently controlled electric steel pipe cutting machine device includes a mounting base 1, a sliding fastening device 2 is provided above the mounting base 1 and along one end of its length direction, and a sliding fastening device 2 is provided above the mounting base 1 and along its The other end of the length direction is provided with a clamping device 3 and a cutting device 4. The sliding fastening device 2 is formed by the middle part of the upper end of the installation base 1 and has a certain length of rectangular chute 5 and rectangular chute 5 along its length direction. The screw mandrel-6 provided in the middle of the inner cavity along its length direction, the moving nut-7 set on the screw mandrel-6, the movable connection assembly-8 set on the outside of the moving nut-7, is arranged in the rectangular chute 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com