Processing mold of hollow bar-shaped konjak

A technology for processing molds and strips, which is applied in the field of hollow strip konjac processing molds to achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

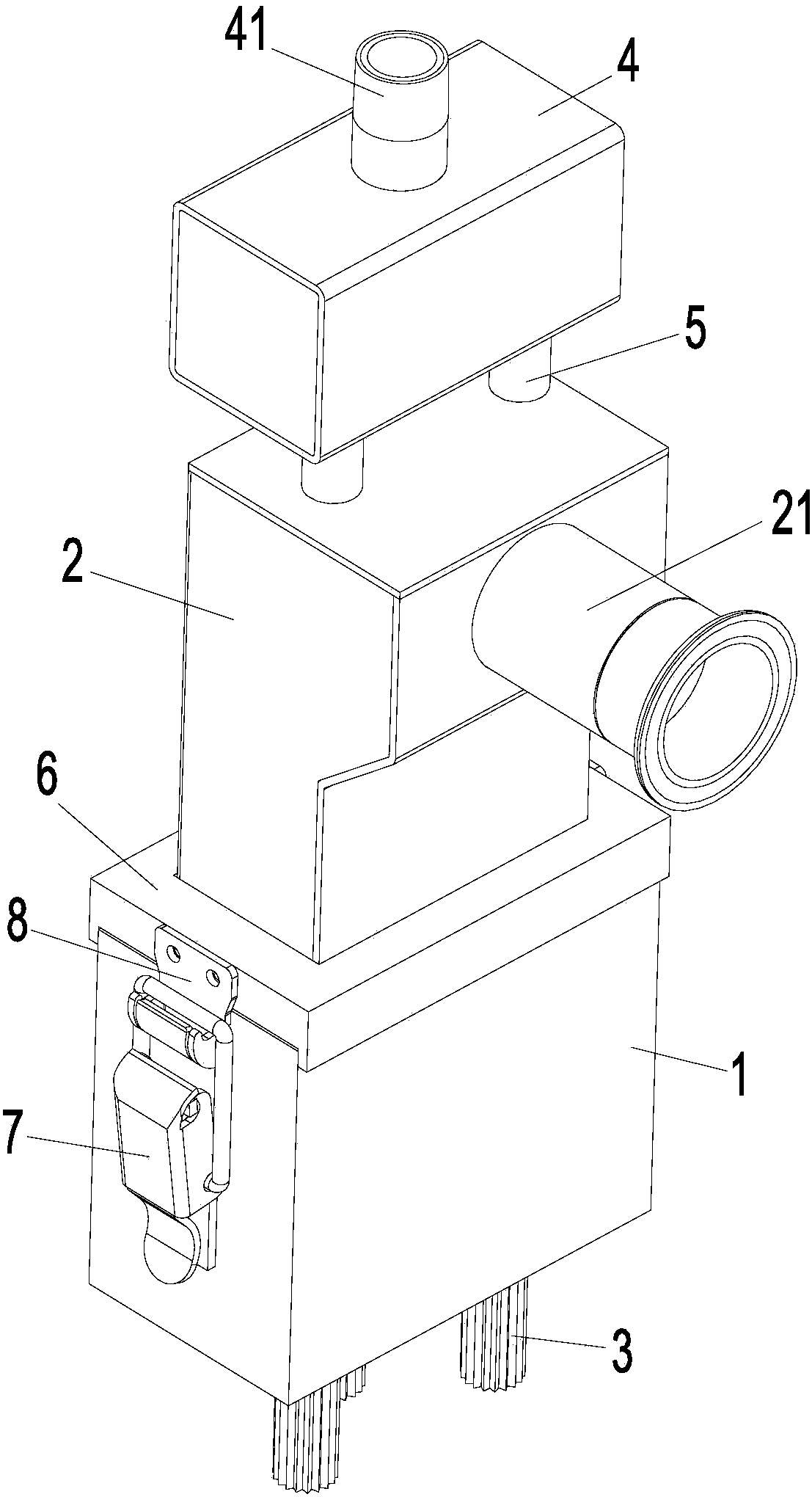

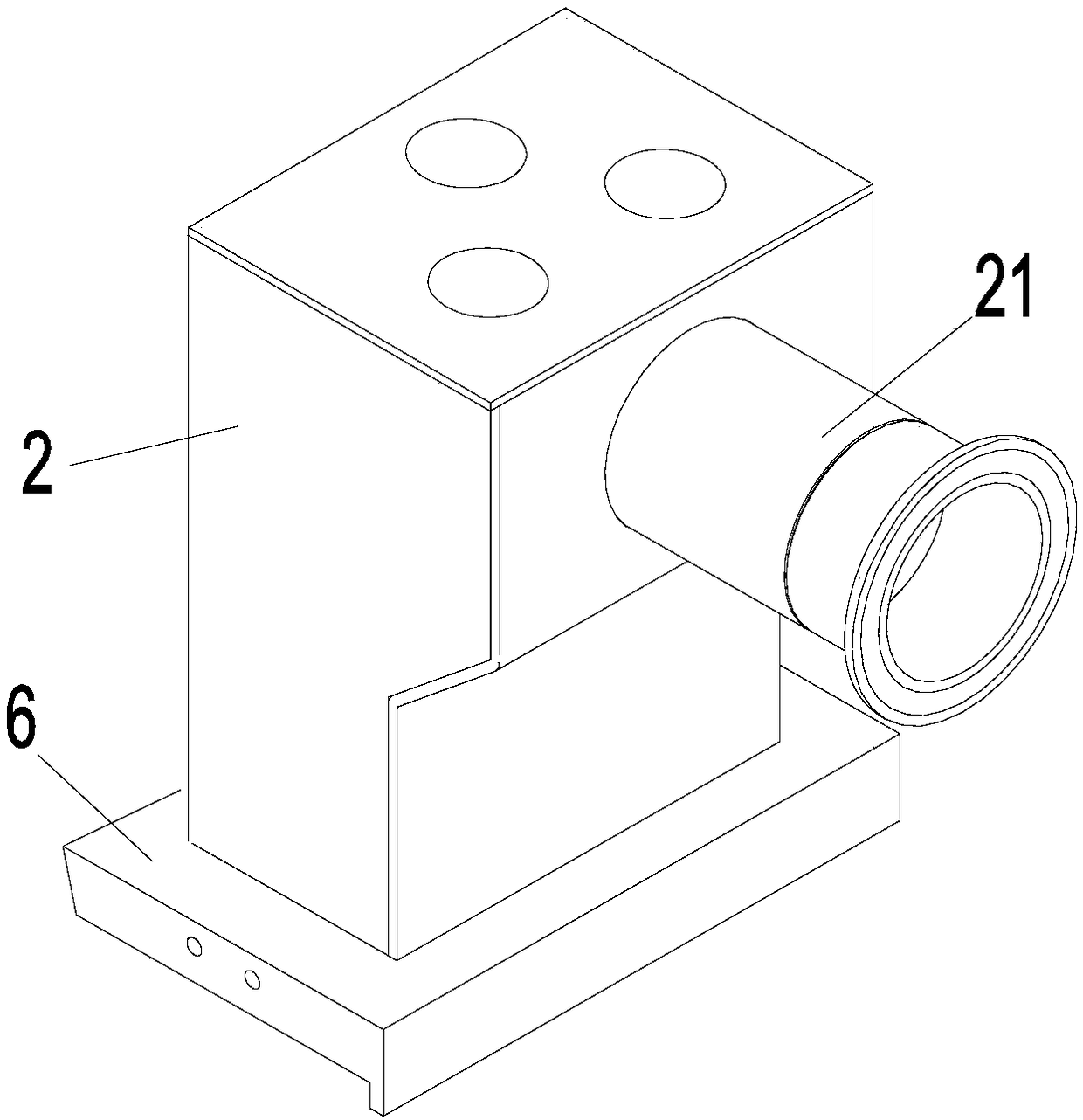

[0033] In the present embodiment, a hollow strip konjac processing mold, such as Figure 1 to Figure 5 As shown, it includes an outer mold 1, a material box 2 and an inner mold 3. The material box 2 is provided with a material inlet 21 and a material outlet. Through the material inlet 21, the user can connect a gear pump to mix the konjac raw material Inject in the material box 2, and make to keep certain pressure in the material box 2, konjac raw material will flow out from the material outlet of above-mentioned material box 2. In this embodiment, the above-mentioned outer mold 1 is provided with a forming through-hole 11, and the above-mentioned forming through-hole 11 is communicated with the material outlet of the above-mentioned material box 2, and the above-mentioned inner mold 3 is connected on the wall of the above-mentioned material box 2 and passes through it in turn. At this time, a forming gap will be formed between the inner mold 3 and the hole wall of the above-m...

Embodiment 2

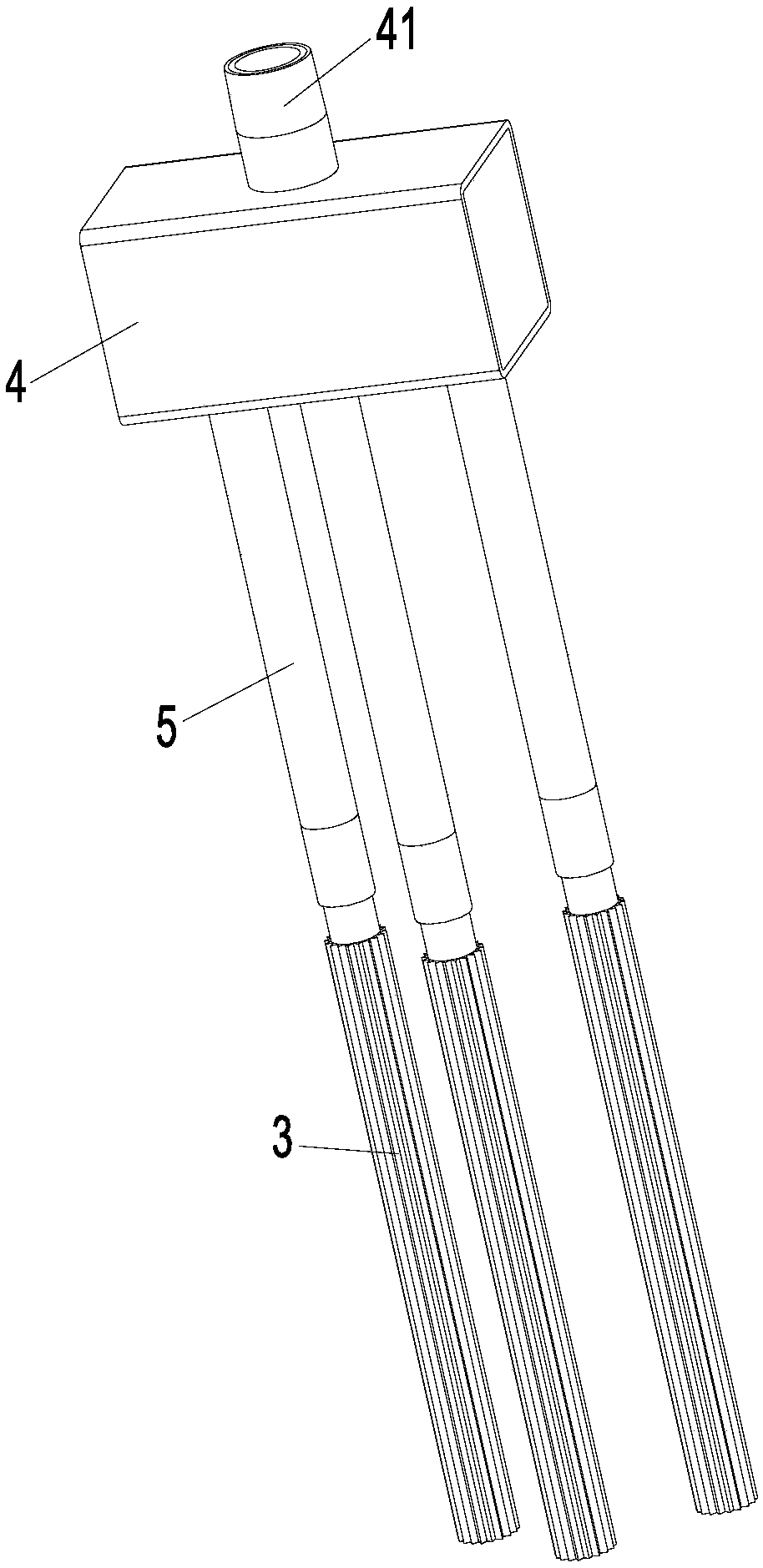

[0035] This embodiment is further improved on the basis of Embodiment 1. In this embodiment, as figure 1 and figure 2 As shown, it also includes a heating structure through which the inner mold 3 is fixedly connected to the wall of the material box 2 . Specifically, the heating structure is defined to include a water tank 4 and a hard water pipe 5. A water inlet 41 is provided on the above-mentioned water tank 4. When in use, the water inlet 41 is communicated with a water pump, and the user can pass the water pump into the water tank 4. Inject hot water (preferably 90° C.), one end of the above-mentioned hard water pipe 41 is communicated with the above-mentioned water tank 4, and the above-mentioned inner mold 3 is defined as a hollow tubular structure, and one end of the inner mold 3 is communicated with and arranged on the above-mentioned hard water pipe 41. another side. During installation, the above-mentioned hard water pipe 41 is passed through the above-mentioned m...

Embodiment 3

[0038] This embodiment is further improved on the basis of the above embodiments, in this embodiment, such as figure 1 , figure 2 and Figure 5 As shown, the inner mold 3 is limited to be strip-shaped, and the outer wall of the inner mold 3 is provided with a surface-expanding groove 31 along its axial direction, so as to increase the contact area between the hollow strip konjac and the inner mold 3, so that the forming The hollow strips of konjac taste more evenly mixed, roasted better and tastes more delicious.

[0039] Specifically, the above-mentioned expanding groove 31 is defined as a V-shaped groove, and the number of expanding grooves 31 on the inner mold 3 is limited to 18, and the 18 expanding grooves 31 are defined as a circular array centered on the axis of the inner mold 3 Distributed on the outer wall of inner mold 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com