Heterogeneous rigid-flexible board and multilayer board card manufacture method based on same

A production method and multi-layer board technology are applied in the fields of printed circuit manufacturing, structural connection of printed circuits, printed circuit components, etc., which can solve the problems of low production efficiency, inconformity with individualization, and multiple interfaces with multiple components, etc., to achieve The structure is simple, the production efficiency is improved, and the connection relationship is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

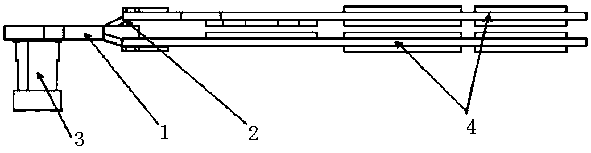

[0042] Such as Figure 1-Figure 3 As shown, a heterogeneous rigid board includes a rigid printed board, a flexible printed board, and an inter-board connector. The inter-board connector used to control the stacking height between two adjacent rigid printed boards is welded on the rigid printed board. At one end of the board, the adjacent rigid printed boards communicate with each other through the inter-board connector. One end of the flexible printed board is printed and connected to the rigid printed board and the other end is detachably connected to the board. The rigidity of the corresponding connection Printed boards and boards communicate with each other through flexible printed boards.

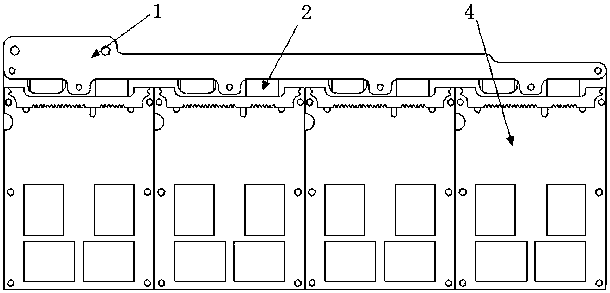

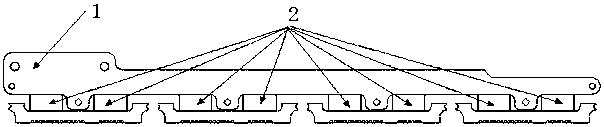

[0043] In this example, if Figure 4 , Figure 5 As shown, a heterogeneous rigid board unit includes a rigid printed board, a flexible printed board, and an inter-board connector. The rigid printed board and the flexible printed board are printed integrally, and the inter-board connec...

Embodiment 2

[0047] A heterogeneous rigid board, including a rigid printed board, a flexible printed board, and an inter-board connector, the inter-board connector used to control the stacking height between two adjacent rigid printed boards is welded at one end of the rigid printed board , signals are communicated between adjacent rigid printed boards through board-to-board connectors, one end of the flexible printed board is printed and connected to the rigid printed board and the other end is detachably connected to the card, and the correspondingly connected rigid printed board , Boards communicate with each other through flexible printed boards.

[0048] In this example, if Image 6 , Figure 7As shown, a heterogeneous rigid board unit includes a rigid printed board, two flexible printed boards, an inter-board connector, a rigid printed board and a flexible printed board on both sides of the rigid printed board / bottom Made of integrated printing, the inter-board connector is welded ...

Embodiment 3

[0051] This embodiment is optimized on the basis of Embodiment 1 or 2. The end of the flexible printed board connected to the board is provided with half-star and half holes for welding and fixing pin pins of the board. The star-moon half-hole is a metallized star-moon half-hole.

[0052] The use of star-moon half-holes can increase the tension of the copper skin on the bottom layer of the surface, prevent the copper skin from falling off, and increase the connection of the bottom layer of the surface.

[0053] Other parts of this embodiment are the same as those of Embodiment 1 or 2 above, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com