Underwater dragging motor of waterproof sealing using oil liquid jacking and capable of deep diving and free of maintenance for underwater diving projects or devices

A drag motor, waterproof sealing technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem that the drag motor has not yet been proposed or introduced, and cannot be permanently used underwater or idle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to realize the above-mentioned purpose of the present invention, intend to adopt following technical scheme:

[0030] The present invention includes:

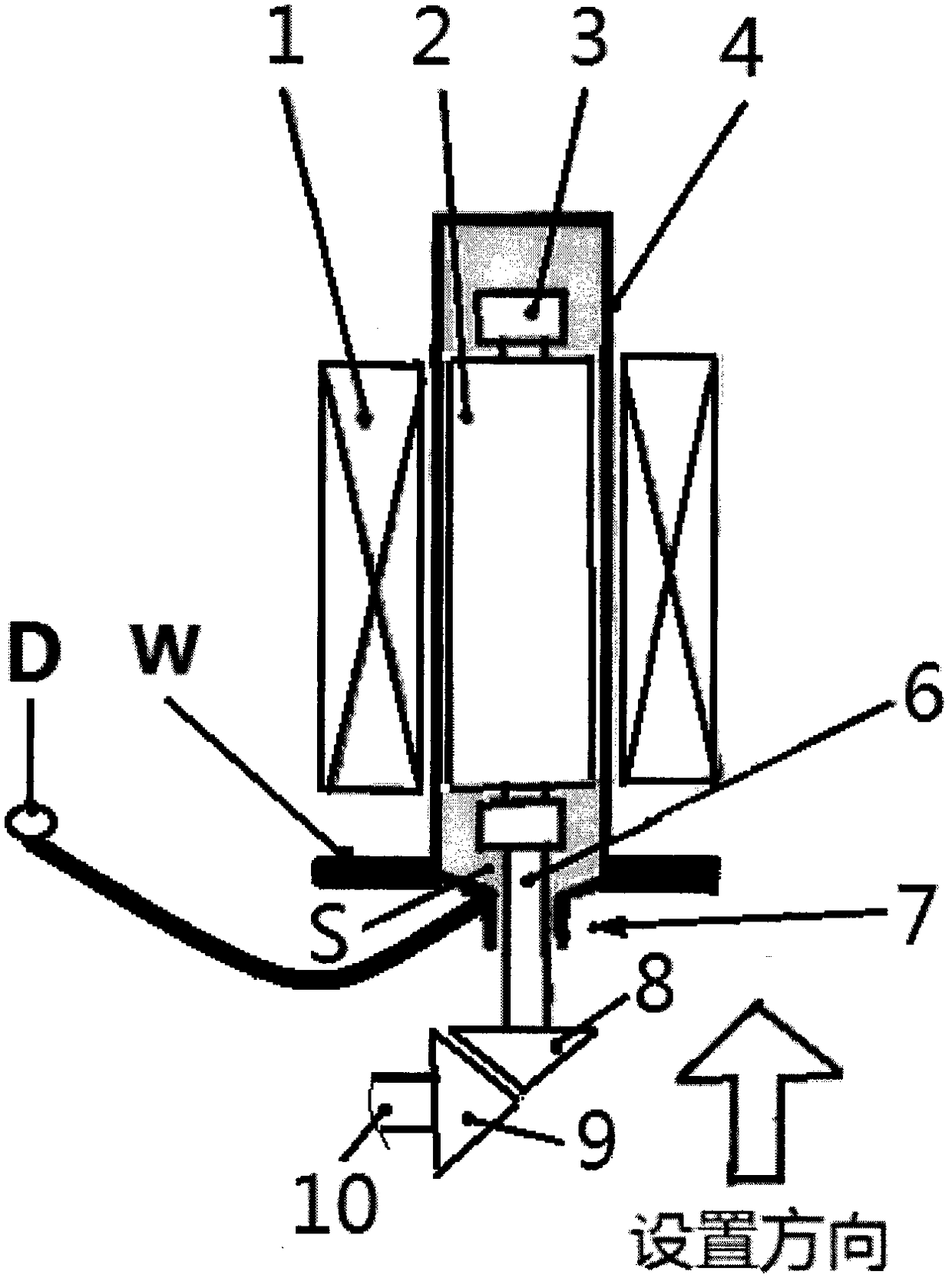

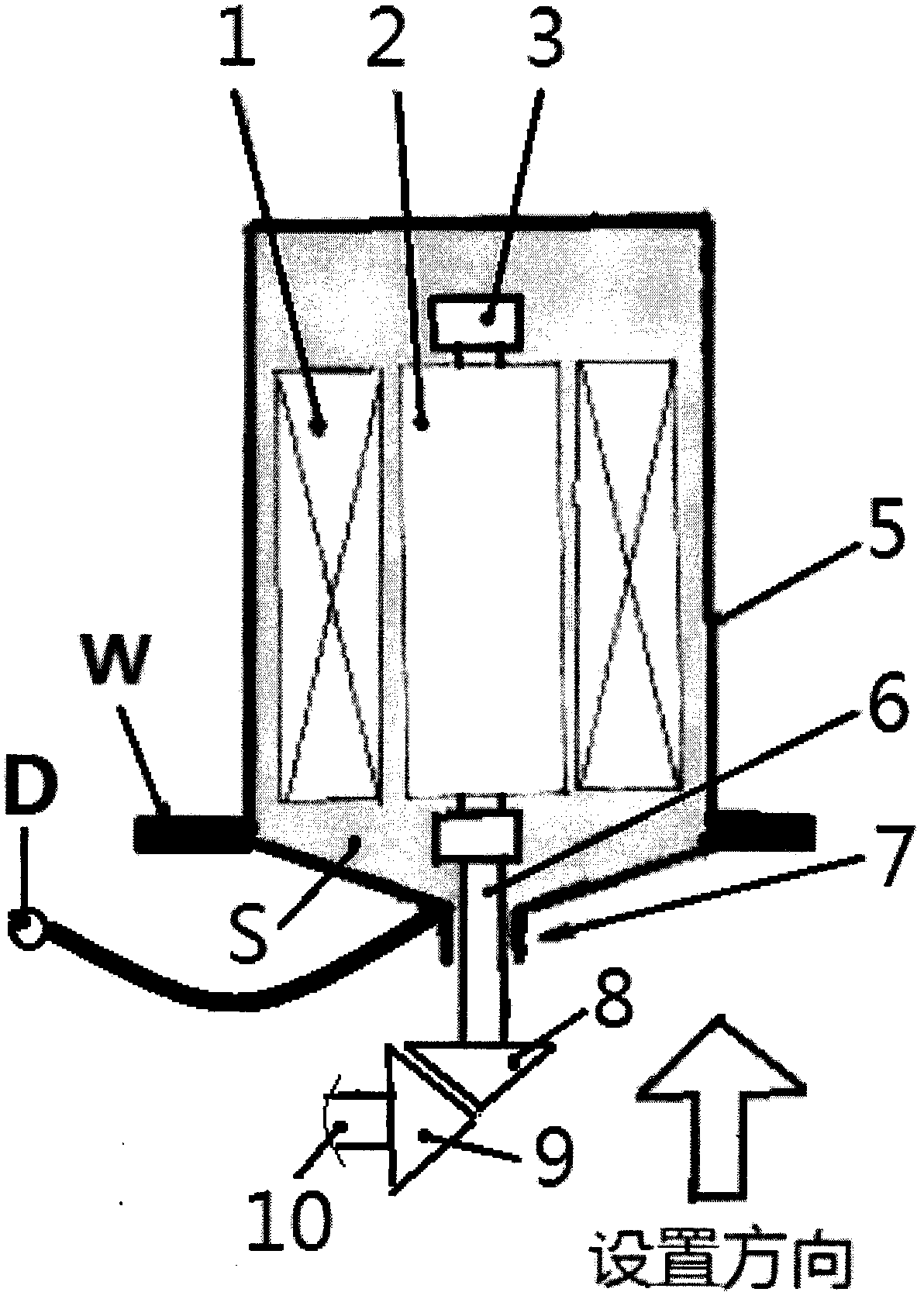

[0031] It includes: a drive motor with a conventional structure consisting of a rotor 2 and a stator 1 embedded in a winding to implement torque output through its rotating shaft 6;

[0032] It is characterized by:

[0033] At least the rotor 2 is surrounded in a three-dimensional form by the narrow metal-sealed isolation shield 4 or the wide-type metal-sealed isolation shield 5, and the bottom of the narrow-type metal-sealed isolation shield 4 or the wide-type metal-sealed isolation shield 5 is provided with a Down through the shaft 6 of the motor shaft seal 7;

[0034] The bottom of the narrow metal-sealed isolation shield 4 or the wide-type metal-sealed isolation shield 5 passes through the pipe union or is directly provided with an oil filling nozzle D;

[0035] The narrow metal-sealed isolation shield 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com